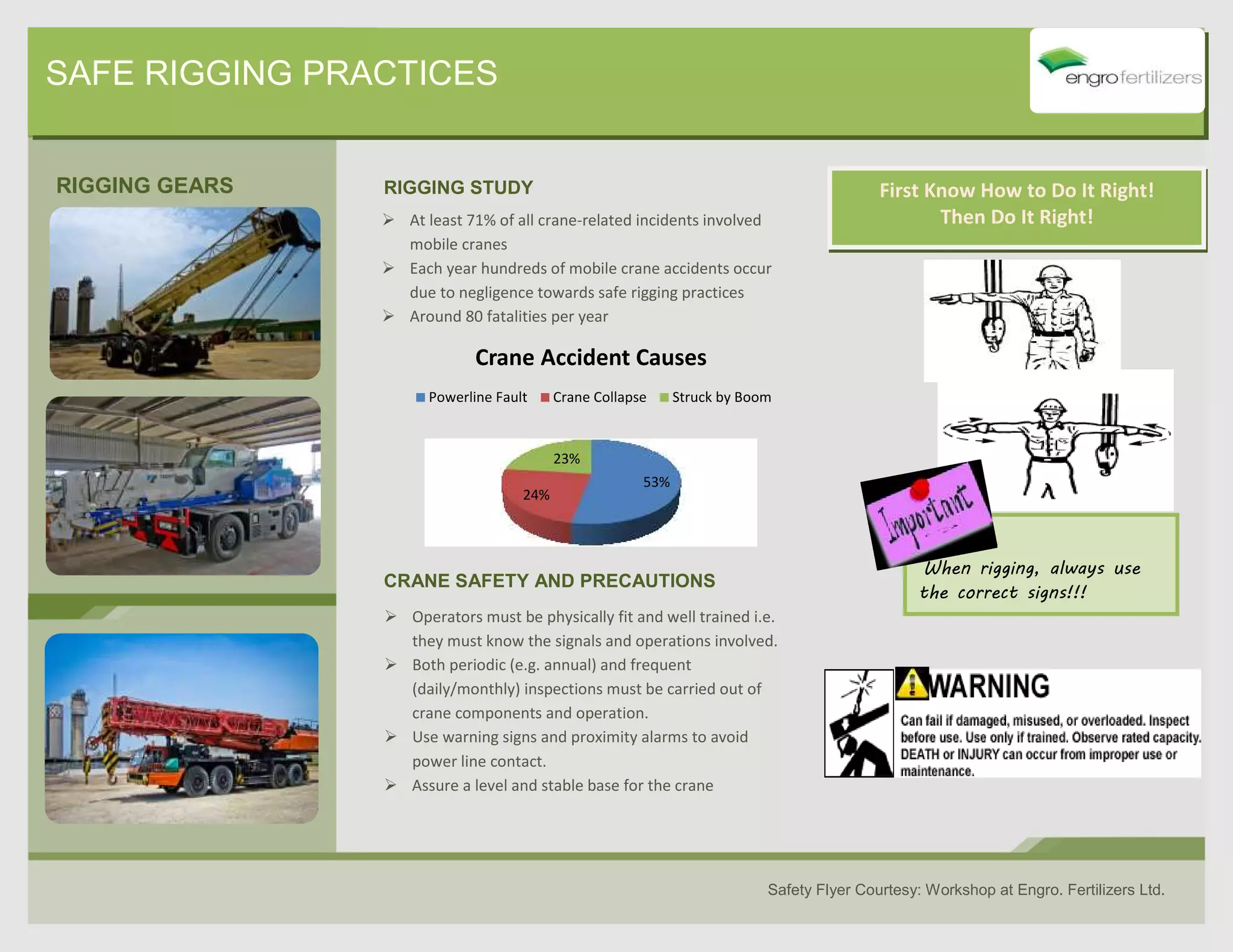

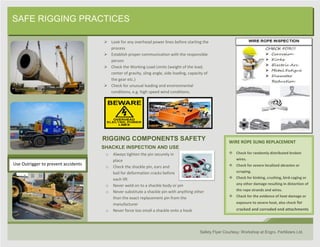

This document provides information on safe rigging practices when using cranes and rigging equipment. It notes that over 70% of crane accidents involve mobile cranes and are often due to negligence of safe rigging practices. Proper inspection and maintenance of equipment as well as ensuring operators are trained are emphasized. Guidelines are provided for inspection of wire rope slings, shackles, and general sling operating practices to prevent accidents and ensure safety.