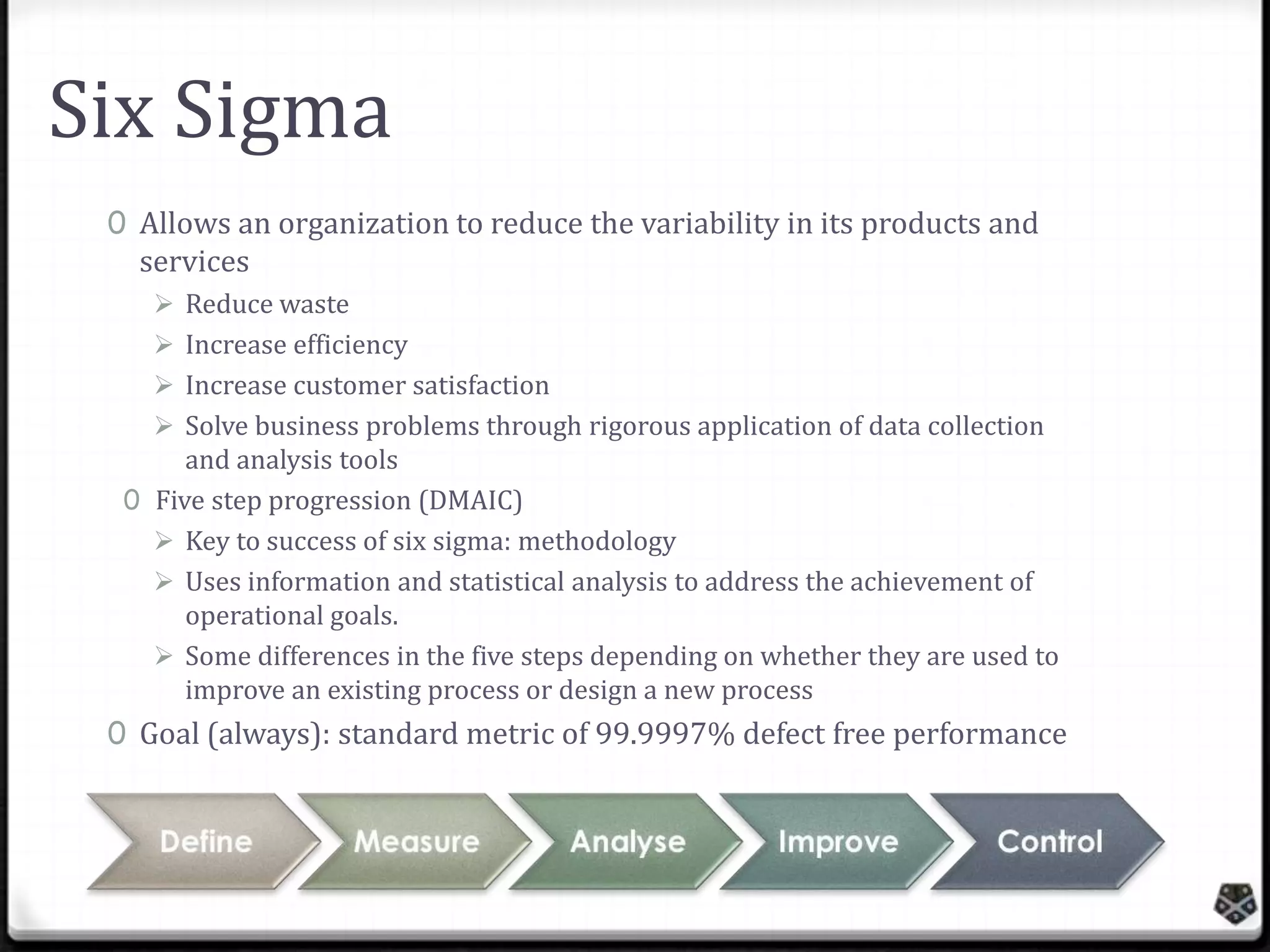

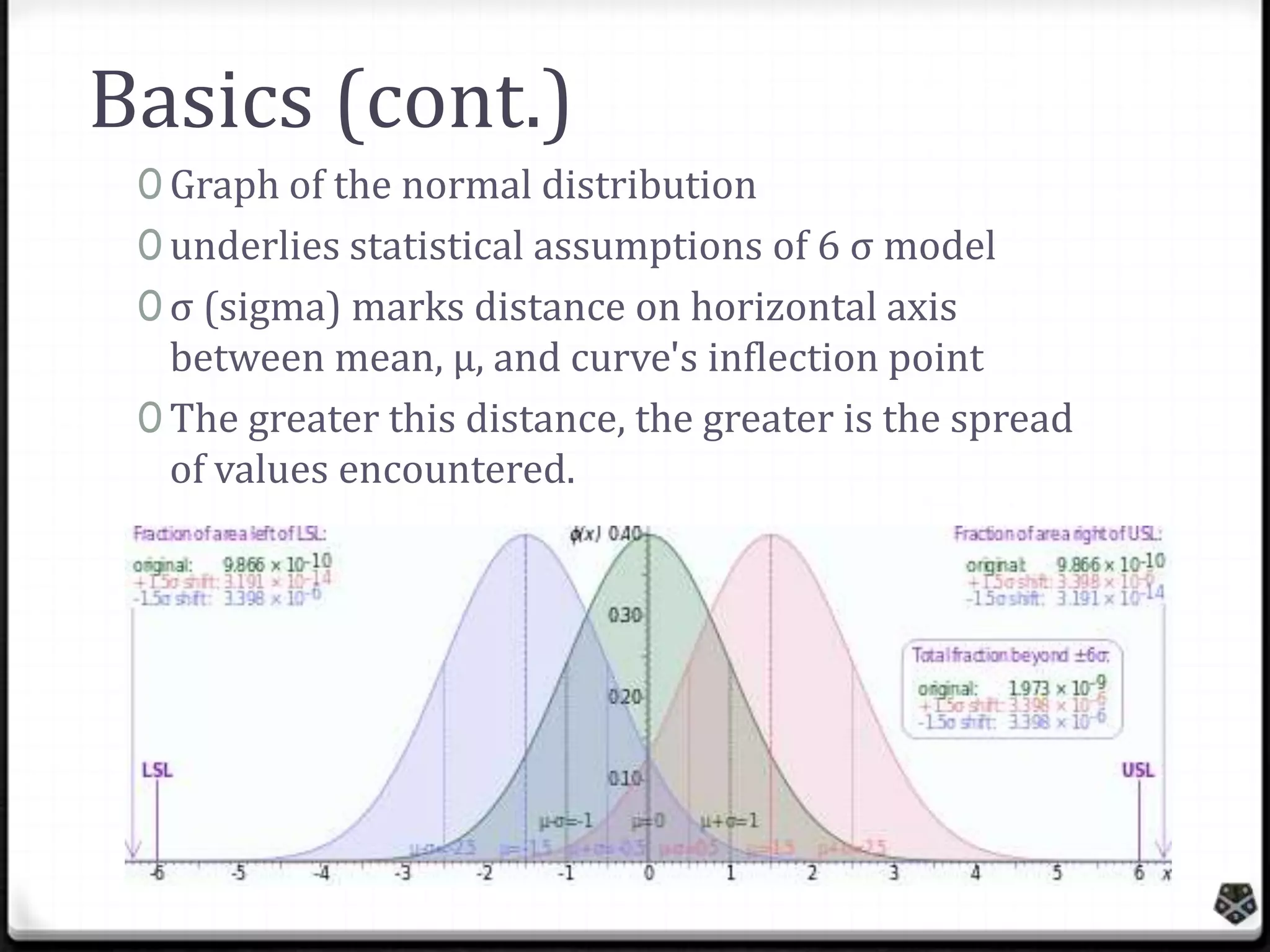

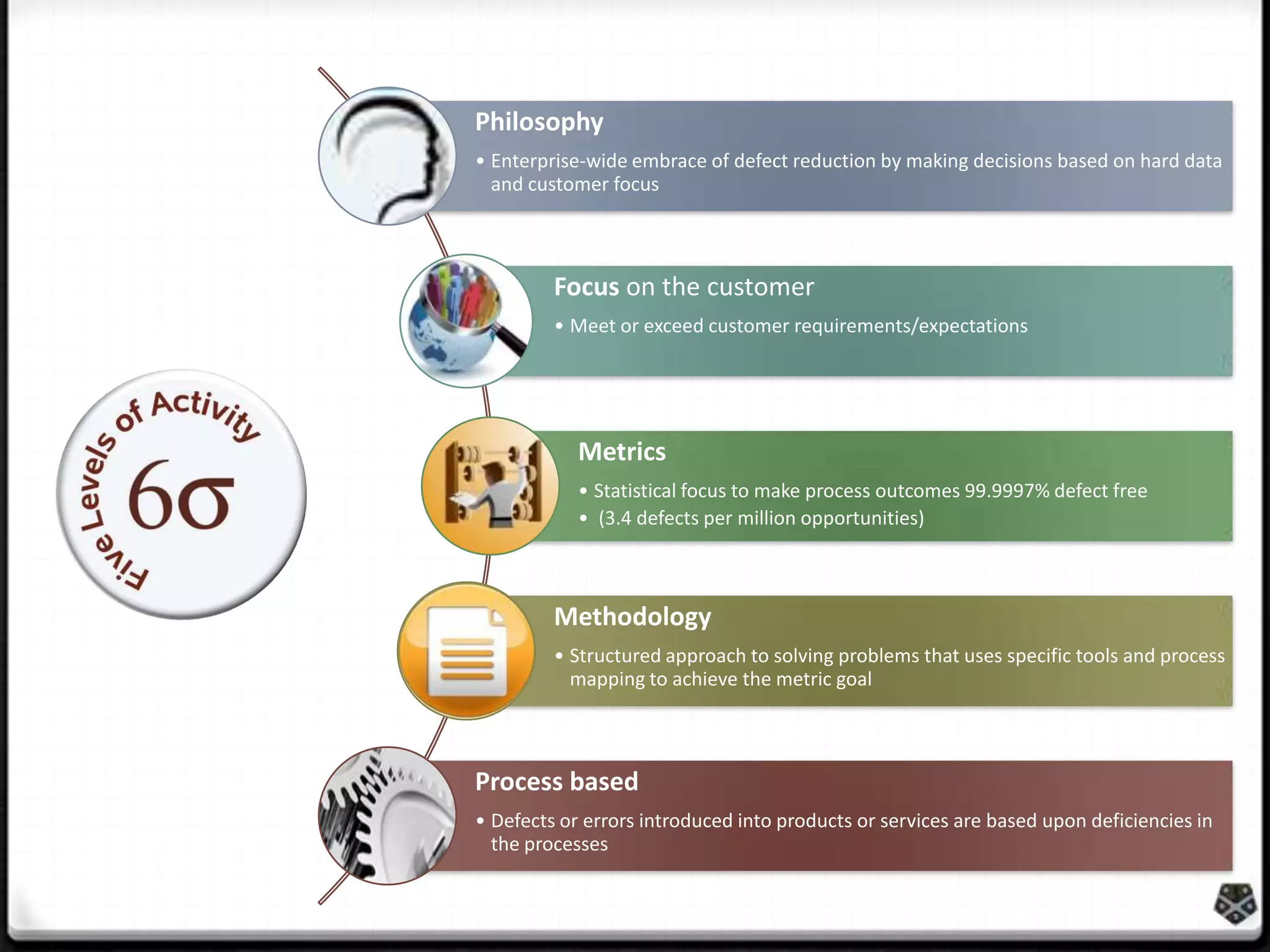

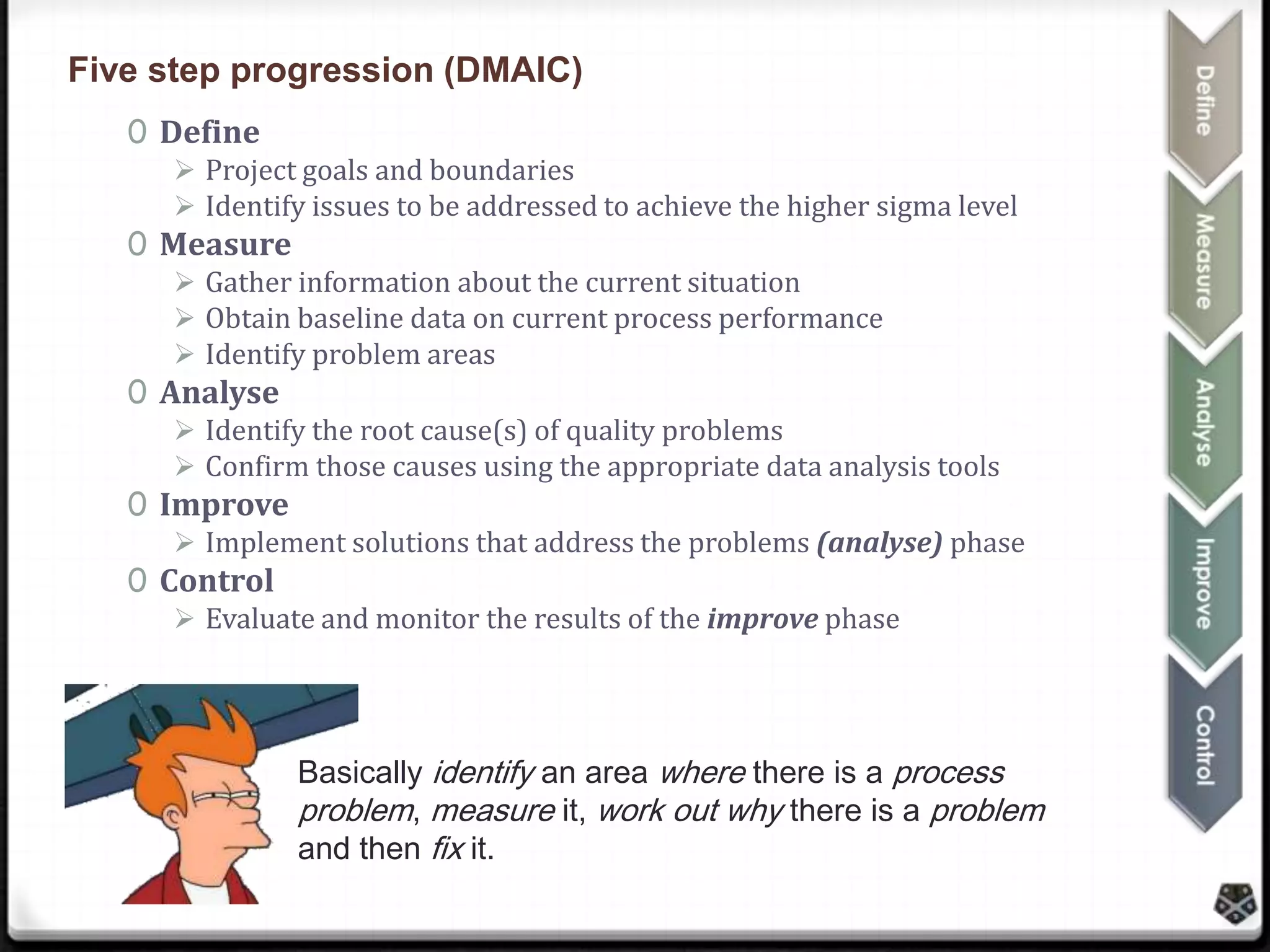

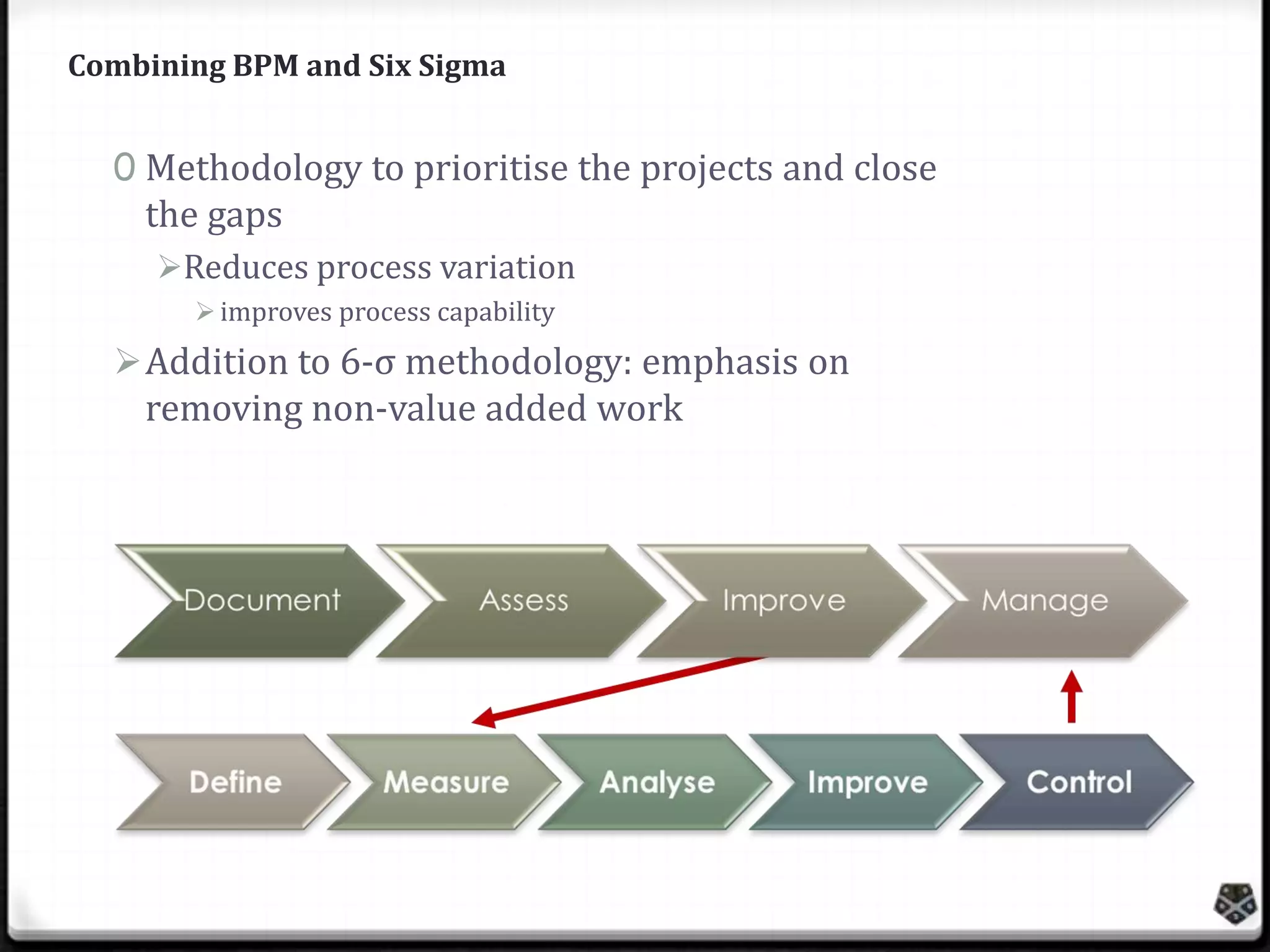

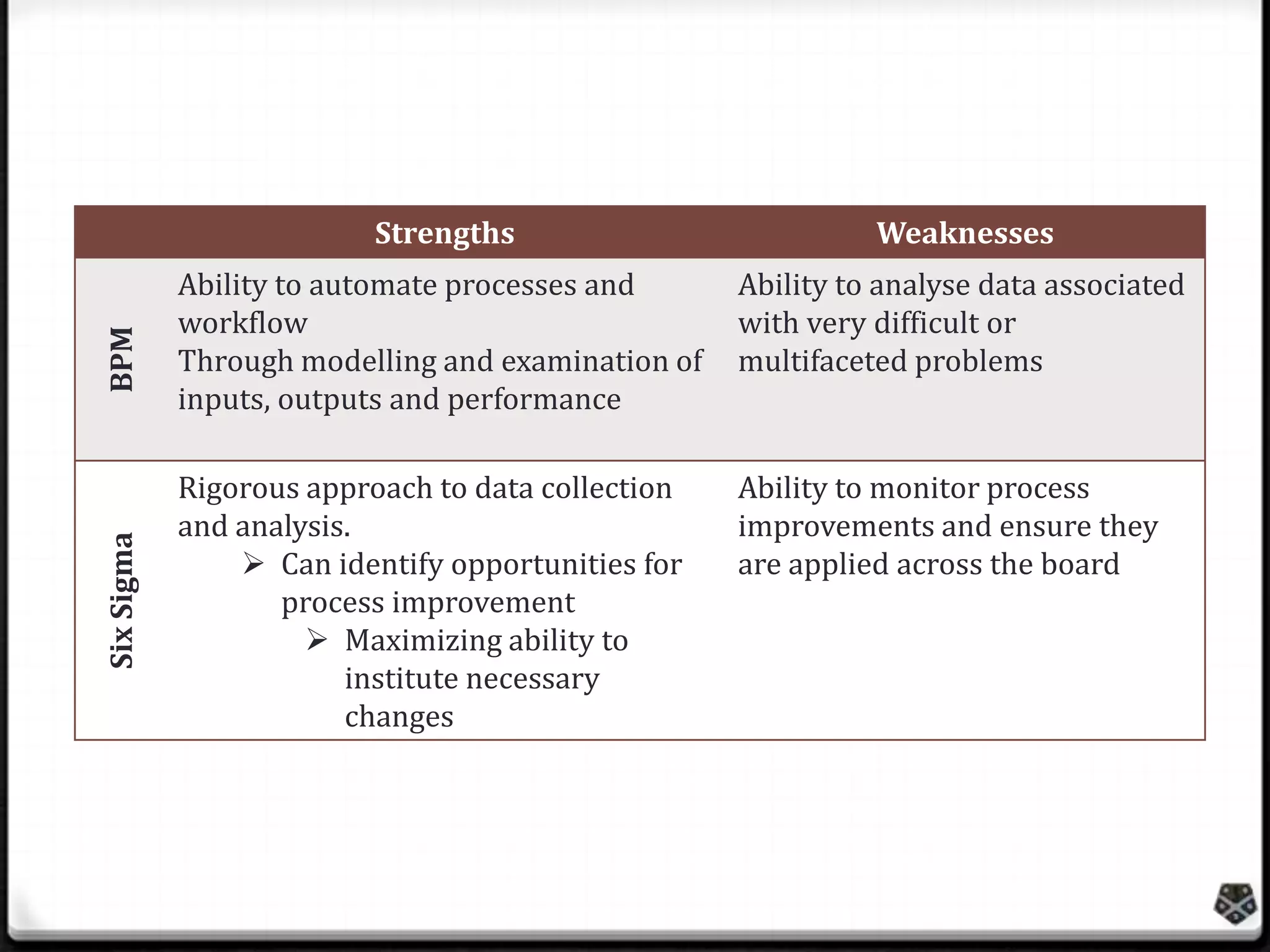

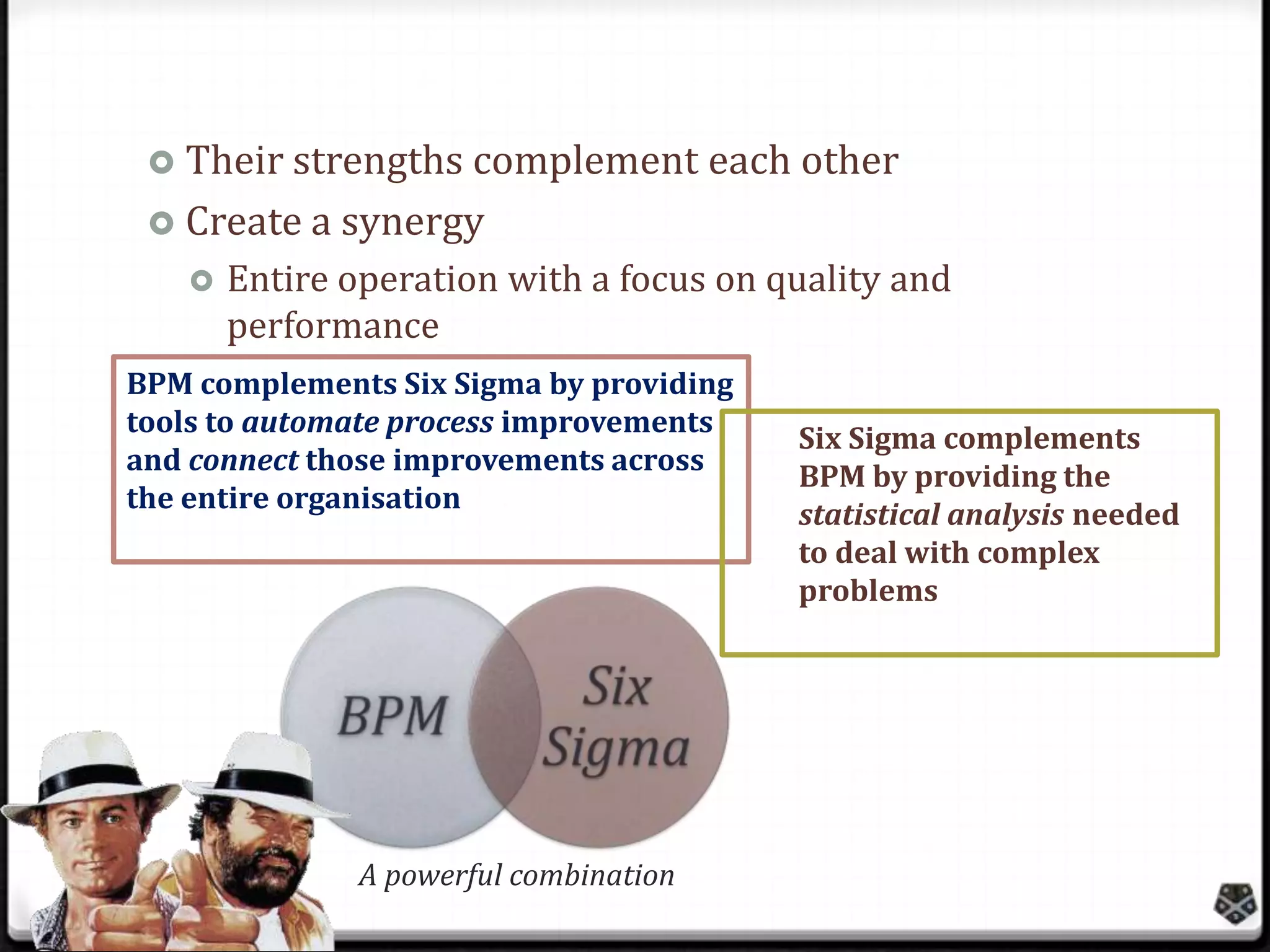

This document provides an overview of Six Sigma, a set of tools and strategies used for process improvement. It was developed by Motorola in the 1980s to improve quality. Six Sigma uses data-driven methods like DMAIC (Define, Measure, Analyze, Improve, Control) to reduce process variability and defects. It aims for near-perfect performance of 3.4 defects per million opportunities. The document also discusses how Six Sigma can be combined with business process management to prioritize improvement projects, remove waste, and monitor changes across an organization.