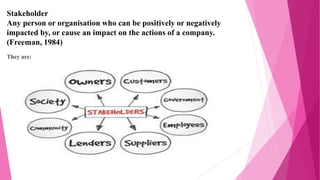

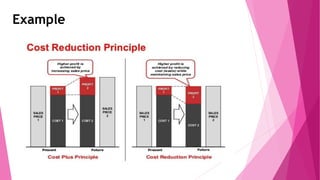

Six sigma is a business methodology for improving quality by reducing defects. It uses statistical tools to measure quality and aims for 3.4 defects per million opportunities. The document outlines the define, measure, analyze, design, and verify phases of a six sigma project. Key tools discussed include stakeholder analysis, Kano modeling, failure mode effects analysis, and control plans. The overall goal is to identify and address root causes of defects in order to achieve process improvements and benefits.