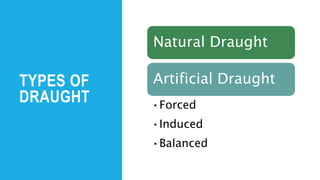

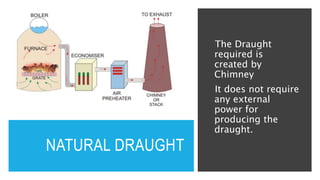

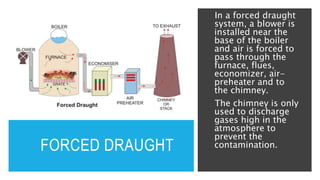

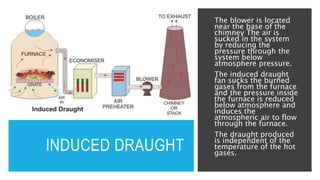

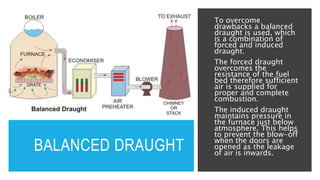

This document discusses boiler draught, which refers to the pressure difference needed to move air and flue gases through a boiler. It describes three types of draught: natural draught created by chimney effect; forced draught using a fan at the boiler's base; and induced draught using a fan at the chimney top. Balanced draught, a combination of forced and induced, helps overcome issues like blowback when opening furnace doors. Artificial draught provides better control and efficiency than natural draught. Losses occur due to friction in moving air and gases through the boiler system.