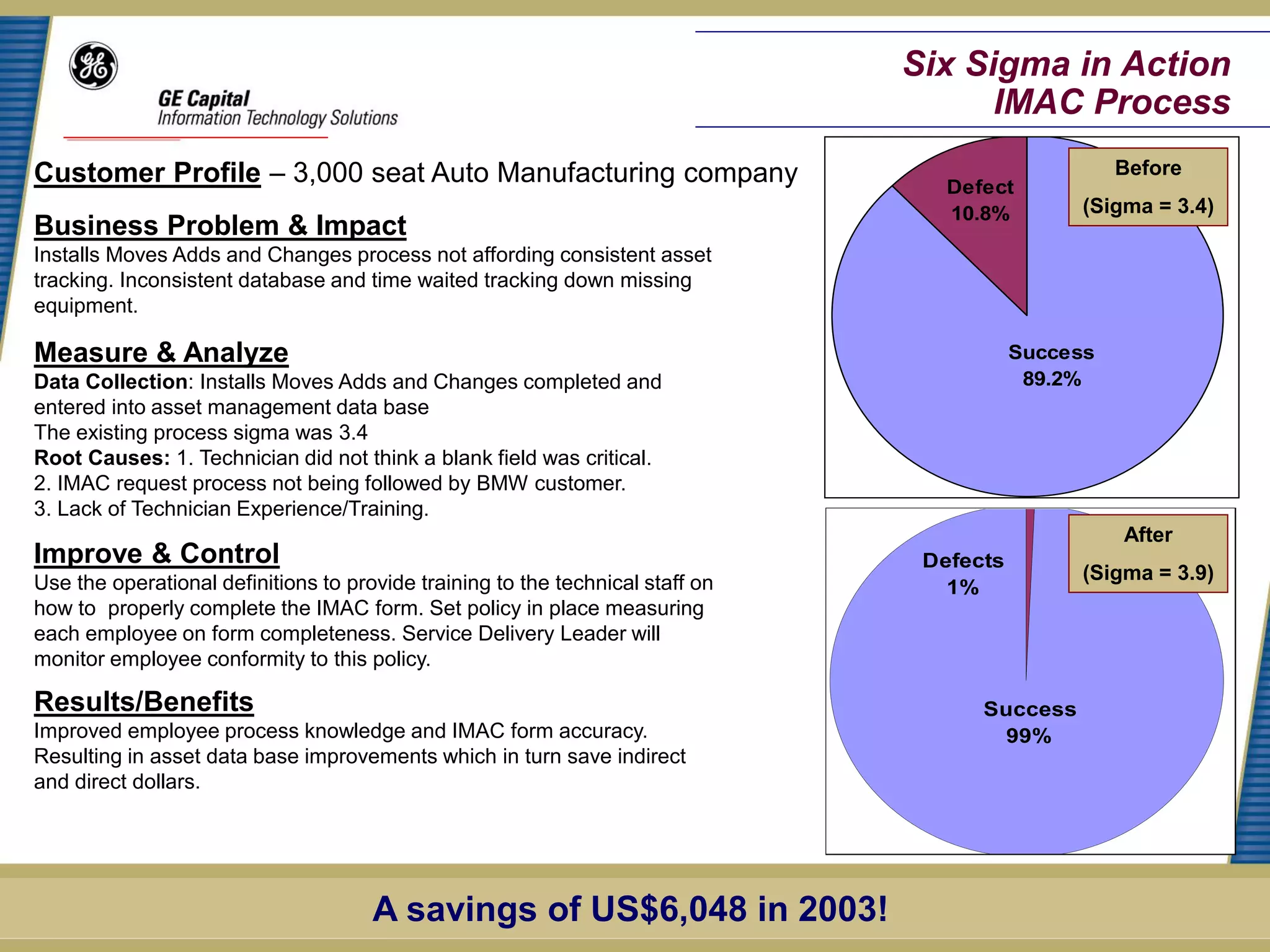

The Six Sigma program at BMW aimed to enhance the IMAC process by addressing a 10.8% defect rate due to inconsistent asset tracking. Key improvements included technician training and policy enforcement, which led to a significant increase in form accuracy to 99% and an improvement in sigma level from 3.4 to 3.9. The initiatives resulted in a cost savings of $6,048 in 2003.