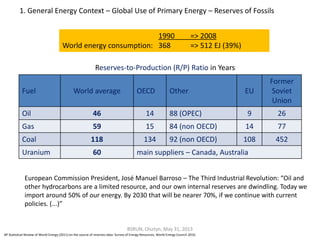

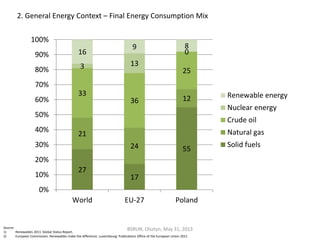

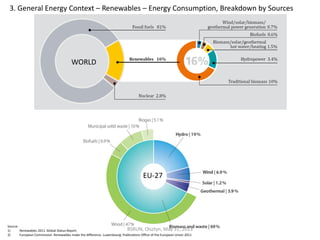

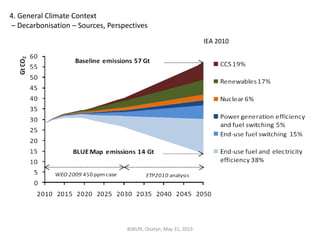

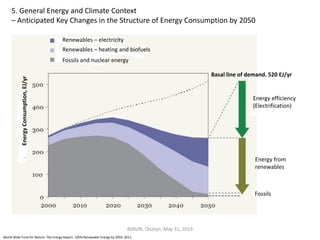

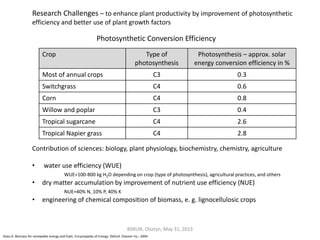

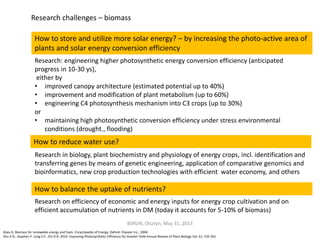

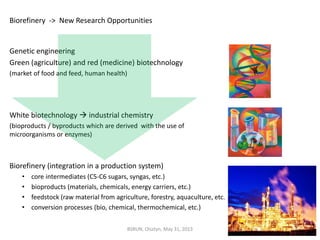

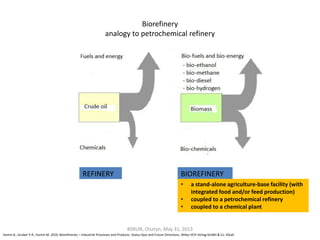

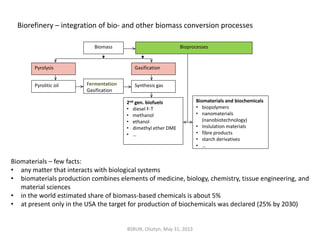

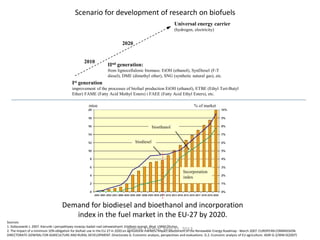

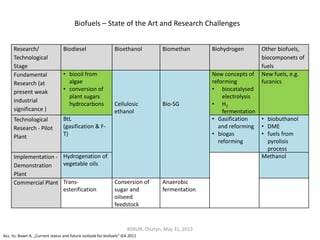

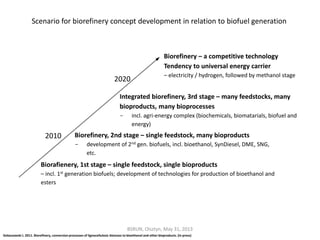

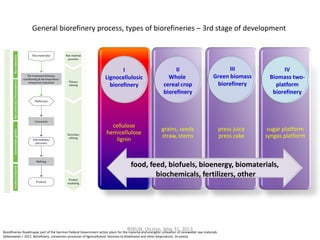

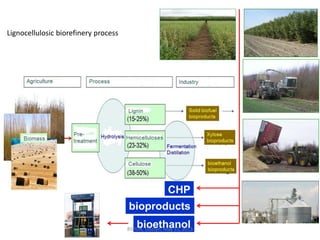

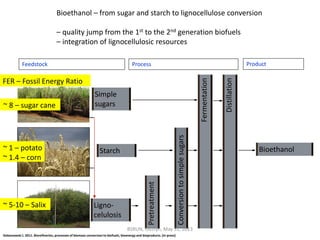

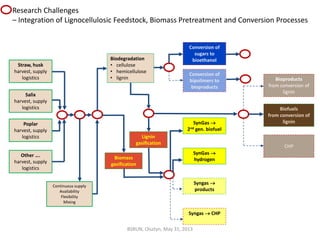

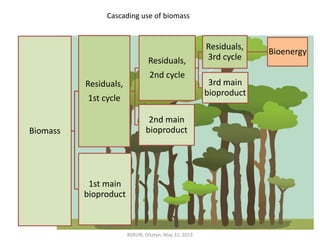

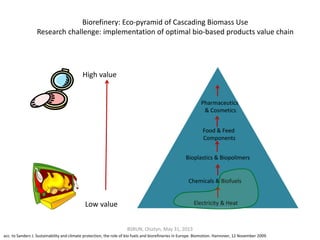

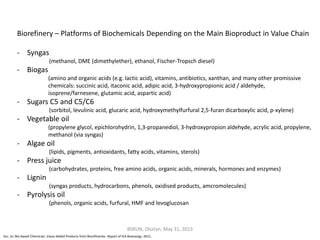

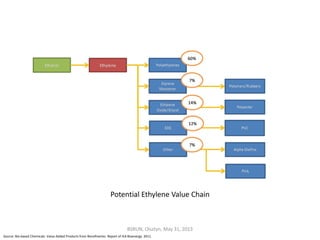

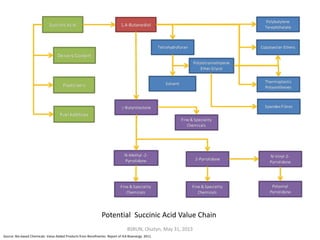

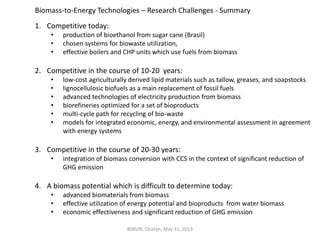

The document discusses the concept of biorefineries and their role in sustainable energy production through biomass. It outlines the need for interdisciplinary research to enhance biomass productivity and improve biomass processing technologies, emphasizing the significance of biofuels and bioproducts. Additionally, it highlights the challenges and opportunities in developing biorefineries to reduce greenhouse gas emissions and transition to renewable energy sources.