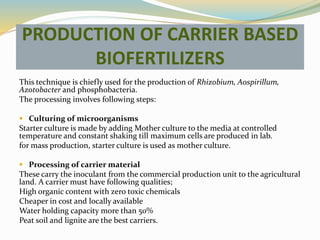

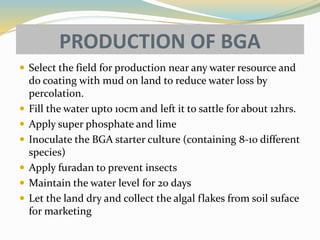

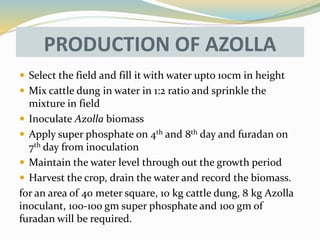

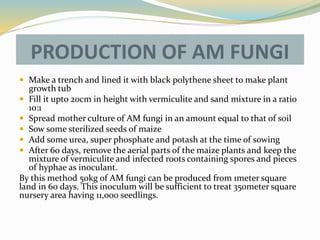

The document discusses biofertilizers, which are eco-friendly substances that use microorganisms to enhance soil fertility and plant growth without harming the environment. It outlines various types of biofertilizers, their production methods, and benefits, including increased nutrient availability and improved crop yields. Additionally, it emphasizes the sustainability of biofertilizers in agriculture and their ability to reduce the reliance on chemical fertilizers and pesticides.