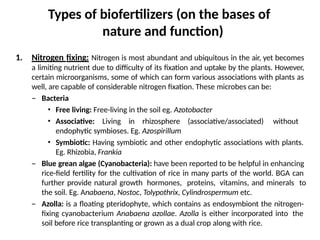

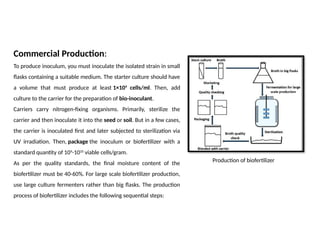

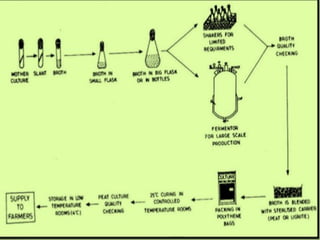

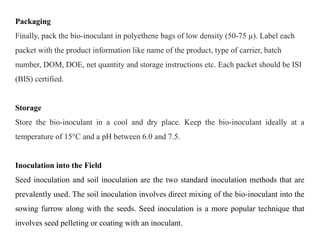

Les biofertilisants sont des substances contenant des micro-organismes vivants qui favorisent la croissance des plantes en augmentant la disponibilité des nutriments. Ils se classifient en plusieurs types, notamment les fixateurs d'azote, les solubilisateurs de phosphore et de potassium, et les bactéries promouvant la croissance des plantes. La production de biofertilisants nécessite une sélection des souches efficaces, leur culture dans des milieux appropriés et des procédures de conditionnement pour garantir la viabilité des cellules.