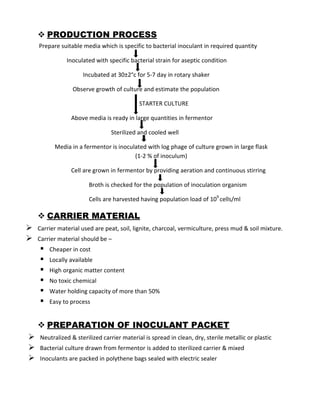

The document discusses biofertilizers, substances containing beneficial microorganisms that enhance soil fertility and plant productivity without the negative impacts of chemical fertilizers. It details types of biofertilizers, their application methods, production processes, and packaging, emphasizing their eco-friendly nature and benefits for soil health and crop yield. Additionally, it describes the favorable characteristics of carrier materials and provides specifications for inoculant packets.