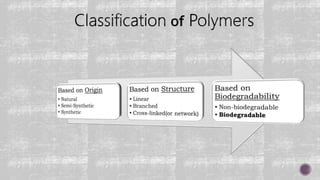

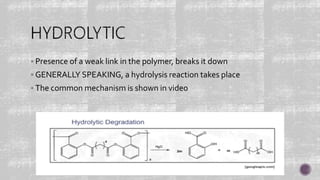

The document discusses biodegradable polymers, their classification, mechanisms of biodegradation, and their applications and benefits. It highlights the importance of natural and synthetic biopolymers in reducing pollution and supporting medical applications, while explaining the role of microorganisms in their degradation. Various techniques for producing biodegradable materials are also detailed, alongside their potential to tackle environmental issues like space debris.