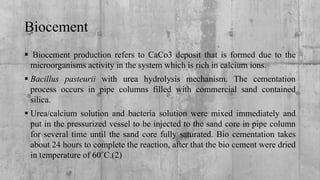

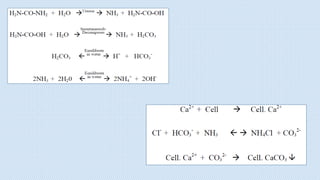

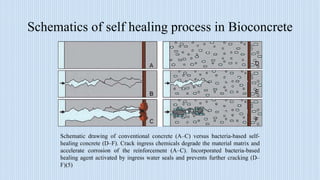

Biocement is produced through microbial activity of organisms like Bacillus pasteurii. When calcium ions and urea are available, these organisms metabolize urea through ureolysis which increases pH and precipitates calcium carbonate to form biogenic cement. This process of microbial induced calcium carbonate precipitation can be used to produce construction materials or remediate cracks through self-healing. Biocrete produced through this process exhibits advantages like reduced CO2 emissions, increased strength, and ability to self-heal cracks compared to ordinary cement. However, successful commercialization requires overcoming challenges like dependence on environmental conditions and high costs of culture media.