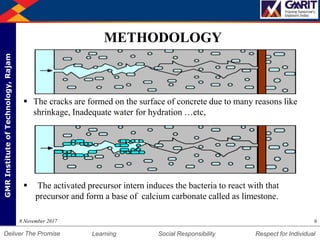

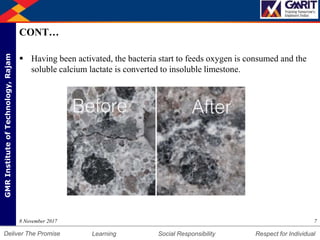

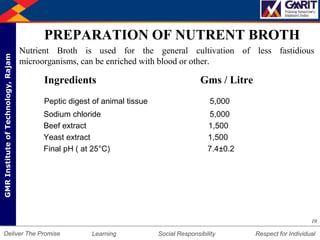

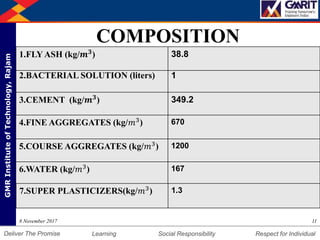

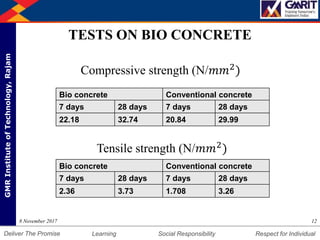

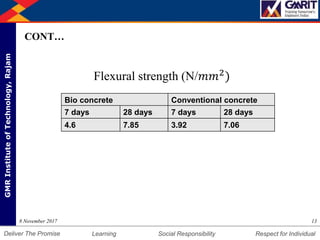

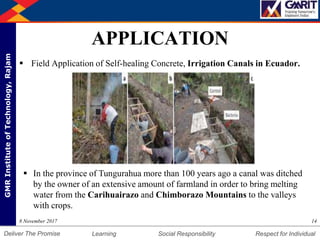

This document summarizes a student project on bio concrete. It includes an abstract stating that bacteria are added to concrete to improve its properties and durability by allowing it to self-heal cracks. It then reviews literature on bacterial concrete and describes the methodology, preparation, composition, and testing of bio concrete. The tests show that bio concrete has higher compressive, tensile, and flexural strength than conventional concrete. Applications discussed include using bio concrete to line irrigation canals in Ecuador to improve water retention.