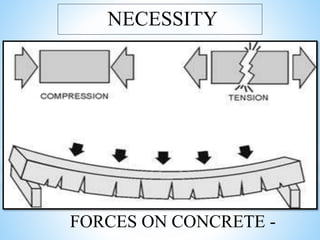

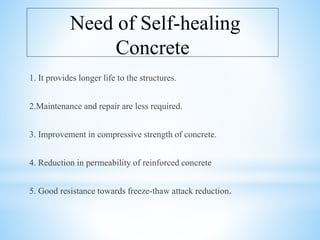

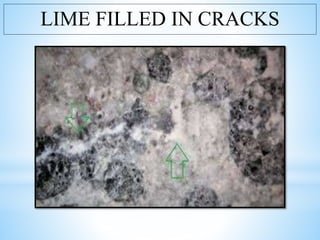

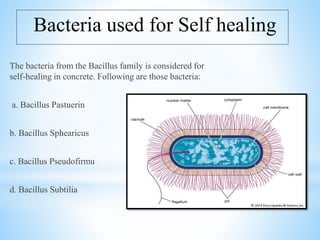

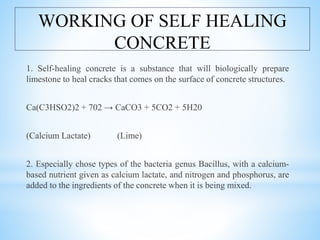

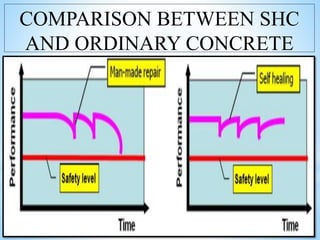

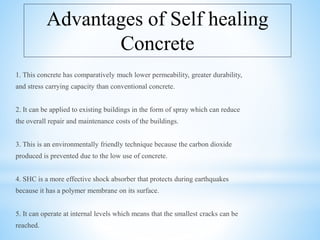

Self-healing concrete contains bacteria that produce limestone to fill cracks. When cracks form from stresses on concrete, the bacteria metabolize calcium lactate to form limestone and fill the cracks. This improves the concrete's strength and durability by reducing permeability and resistance to cracking. Testing on self-healing concrete structures shows it can repair cracks up to 0.5mm wide and protects reinforcement from corrosion compared to ordinary concrete that requires more maintenance.