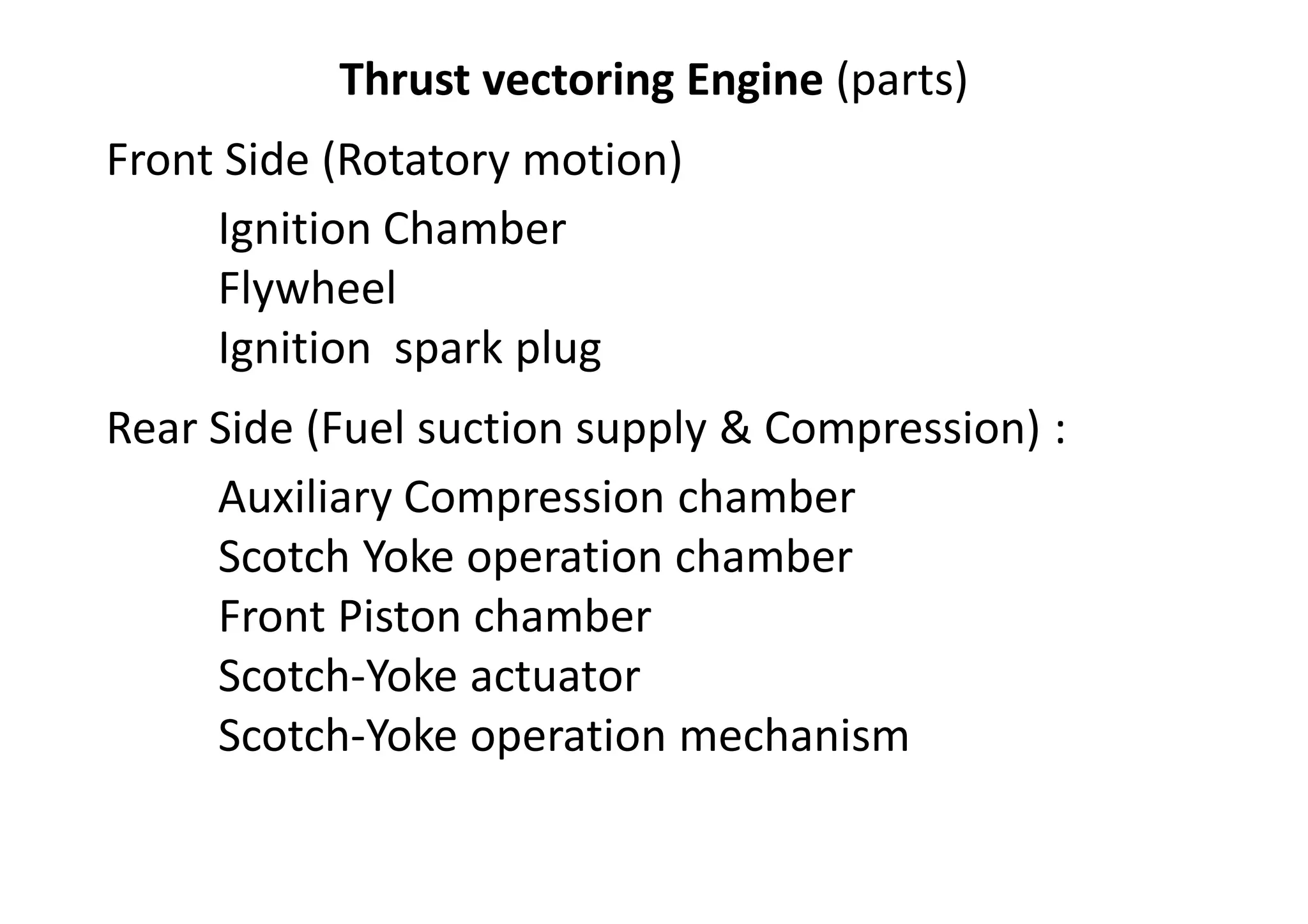

The document describes a reciprocating rotary engine design consisting of the following key components:

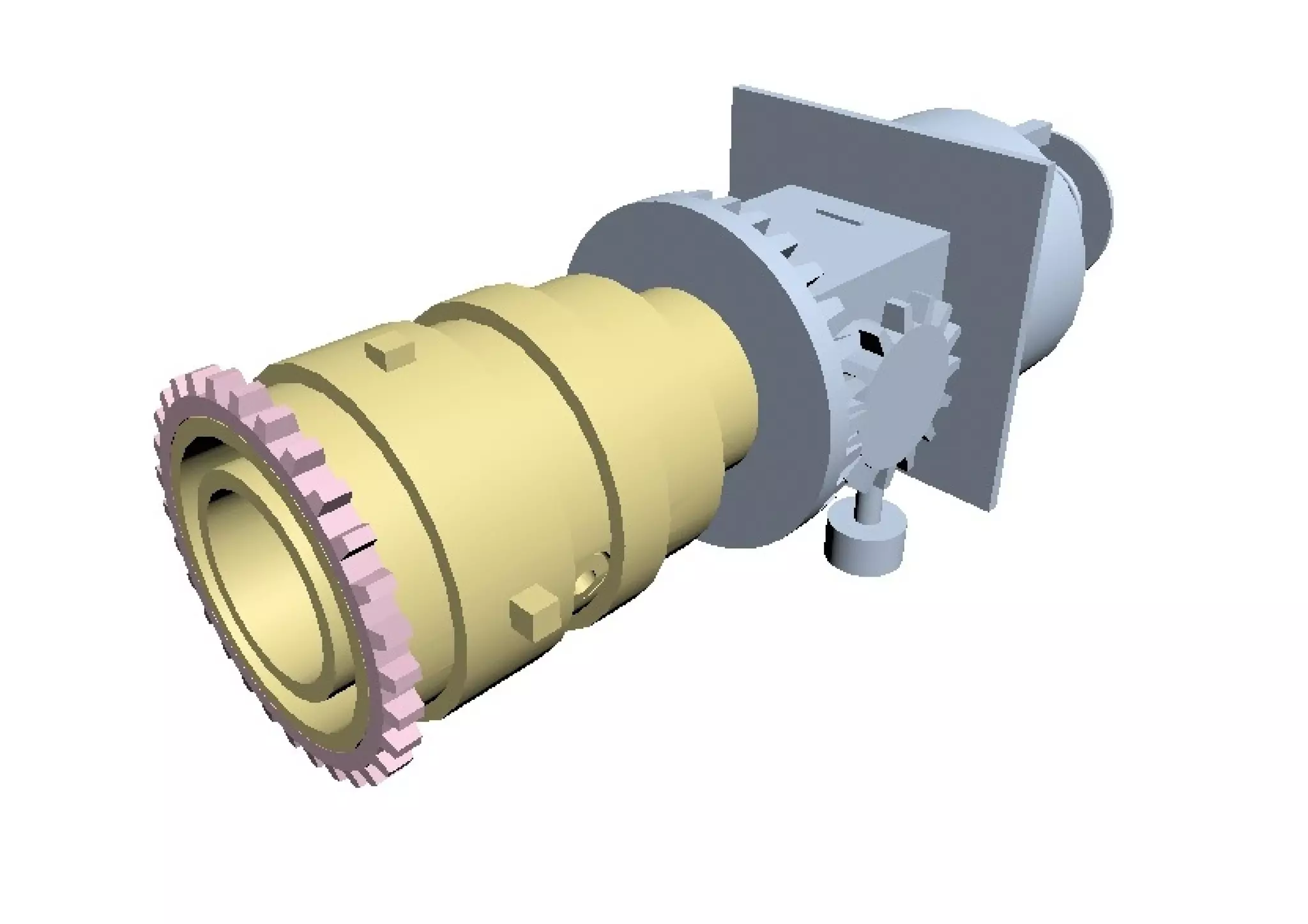

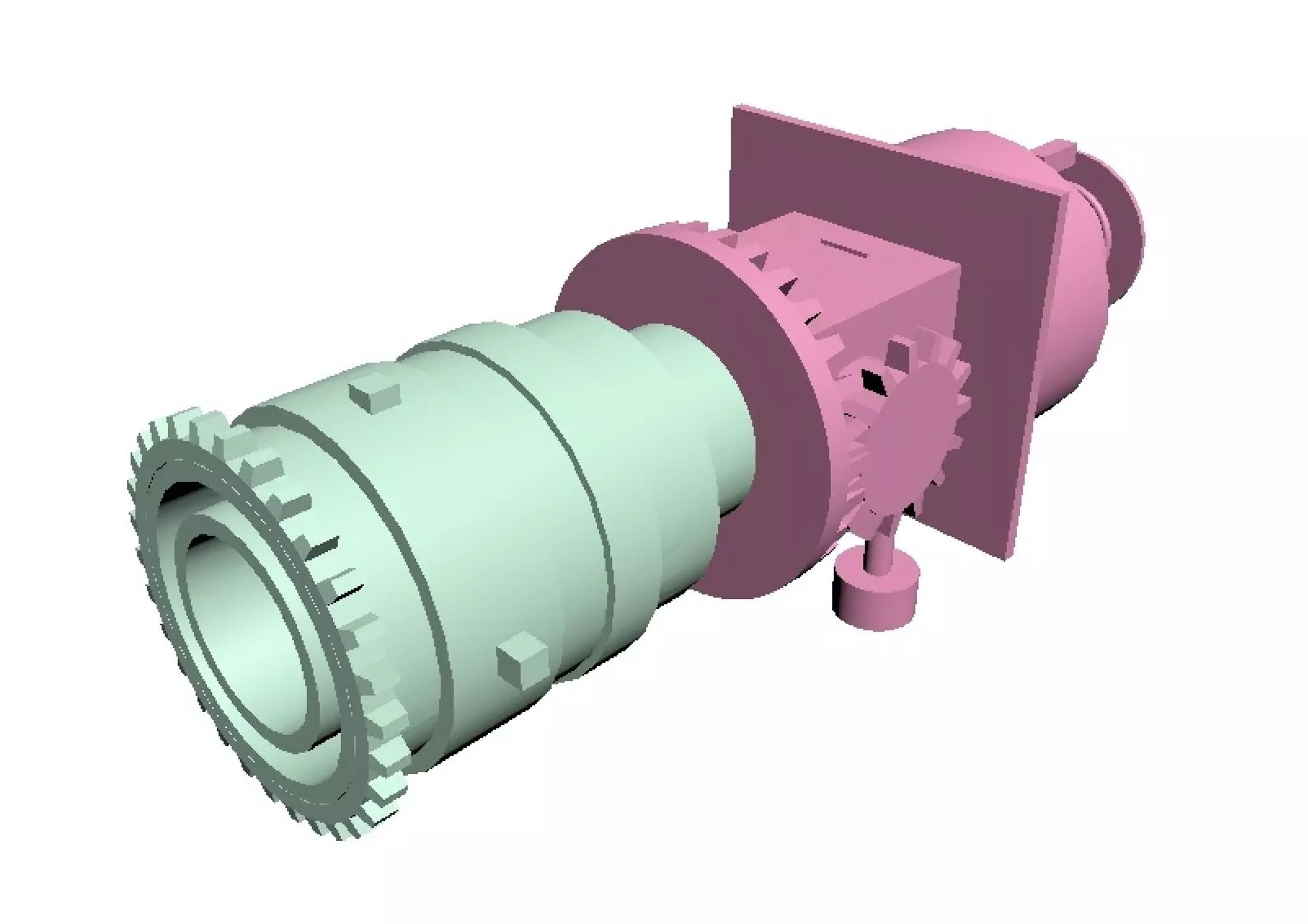

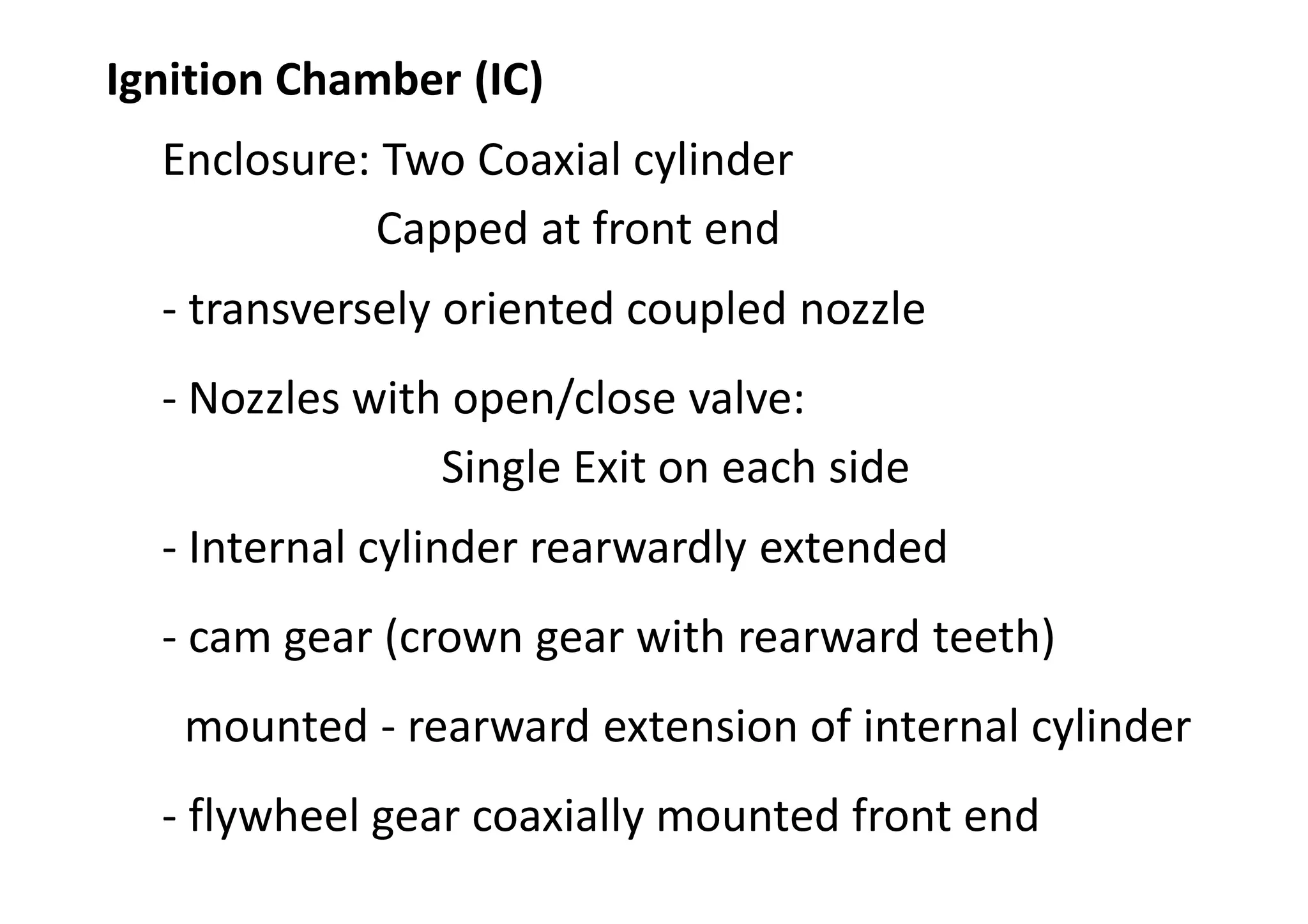

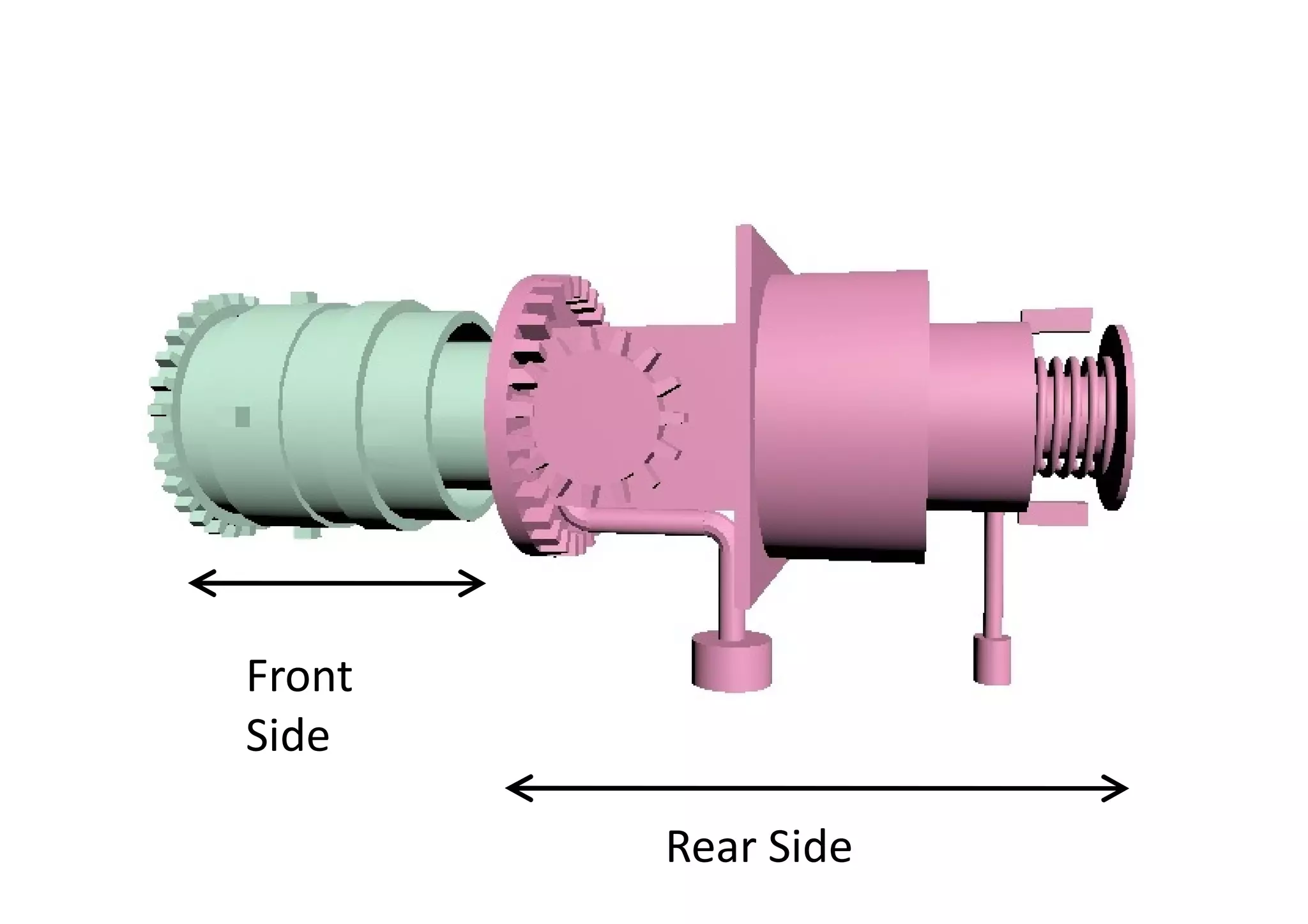

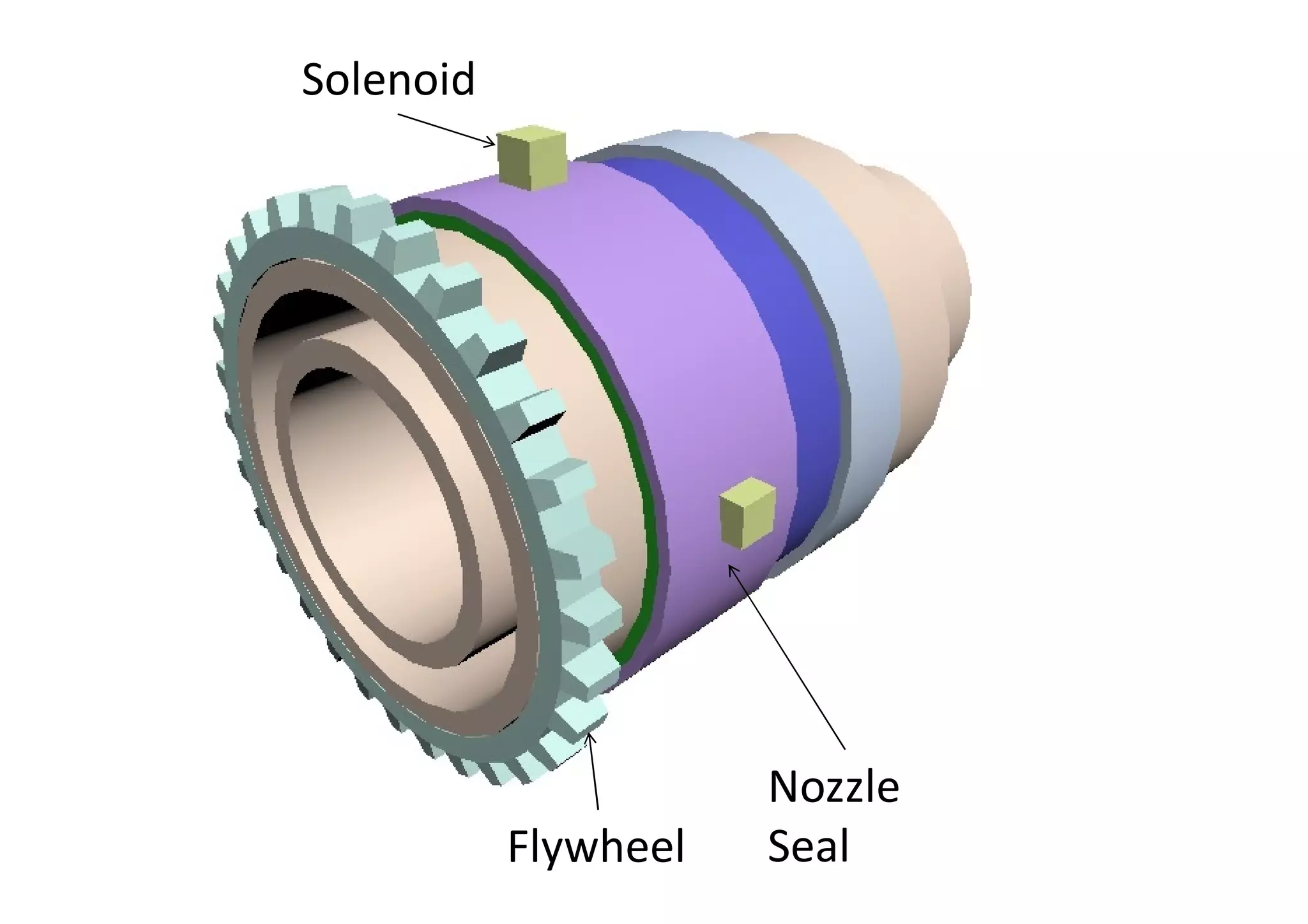

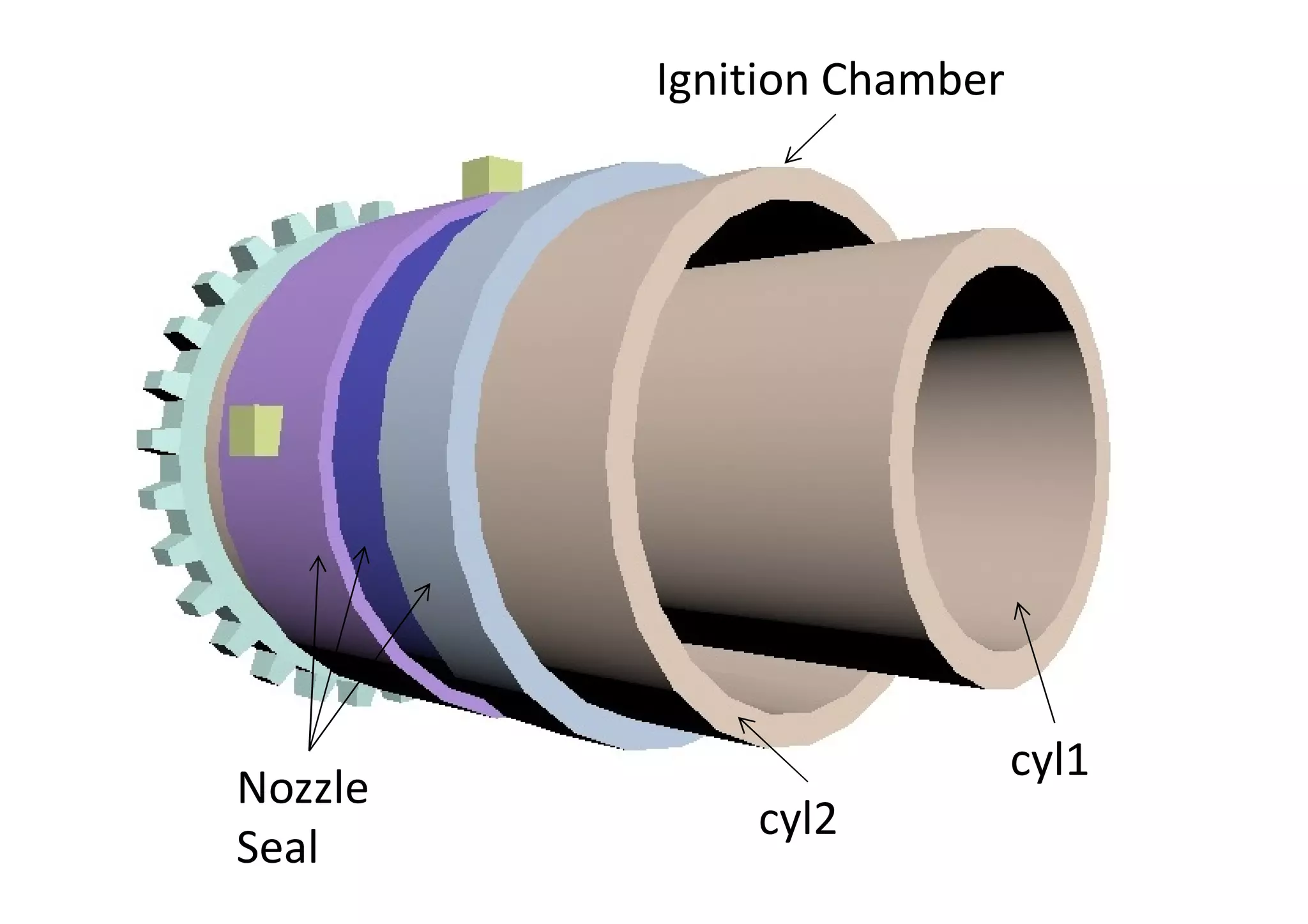

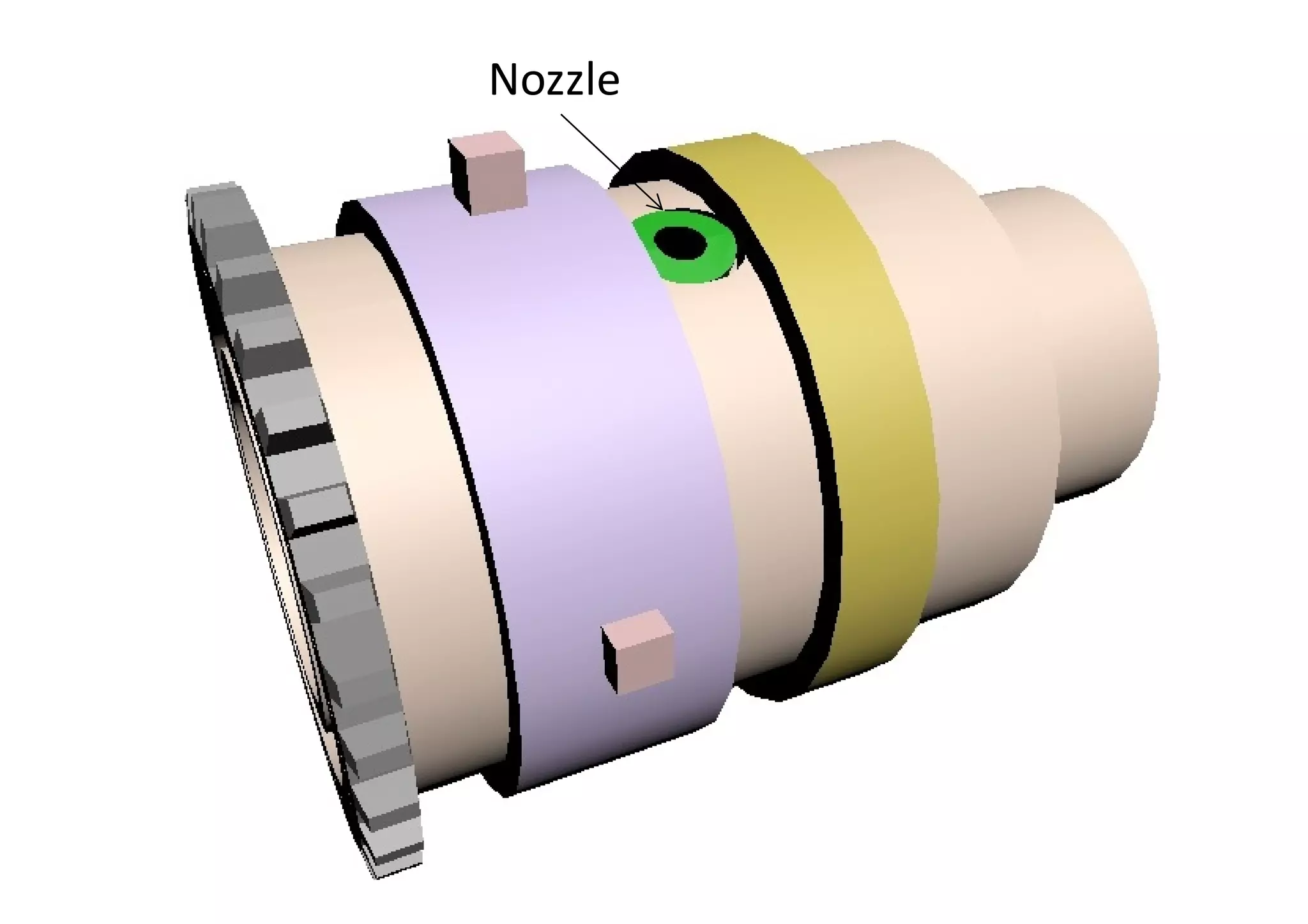

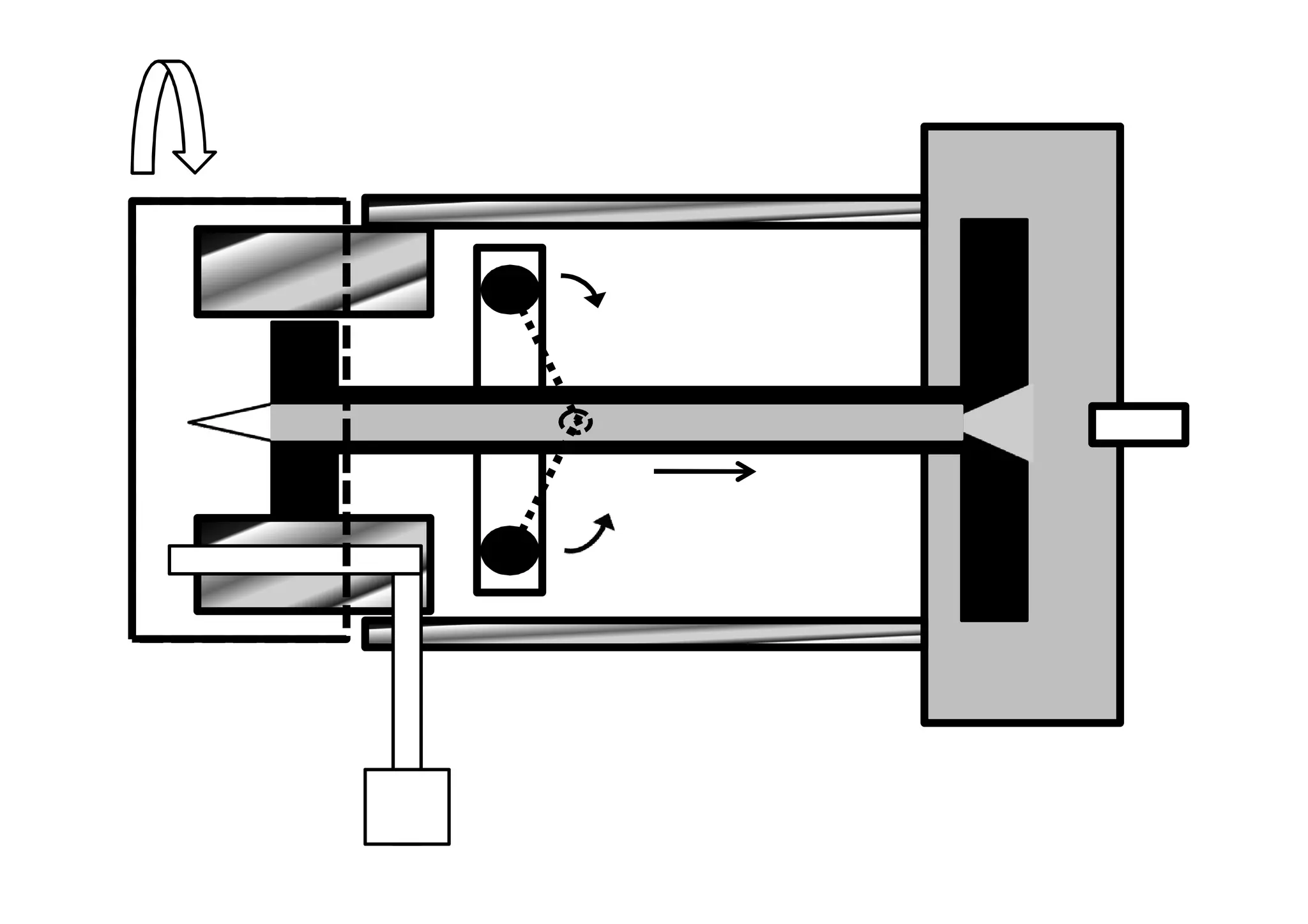

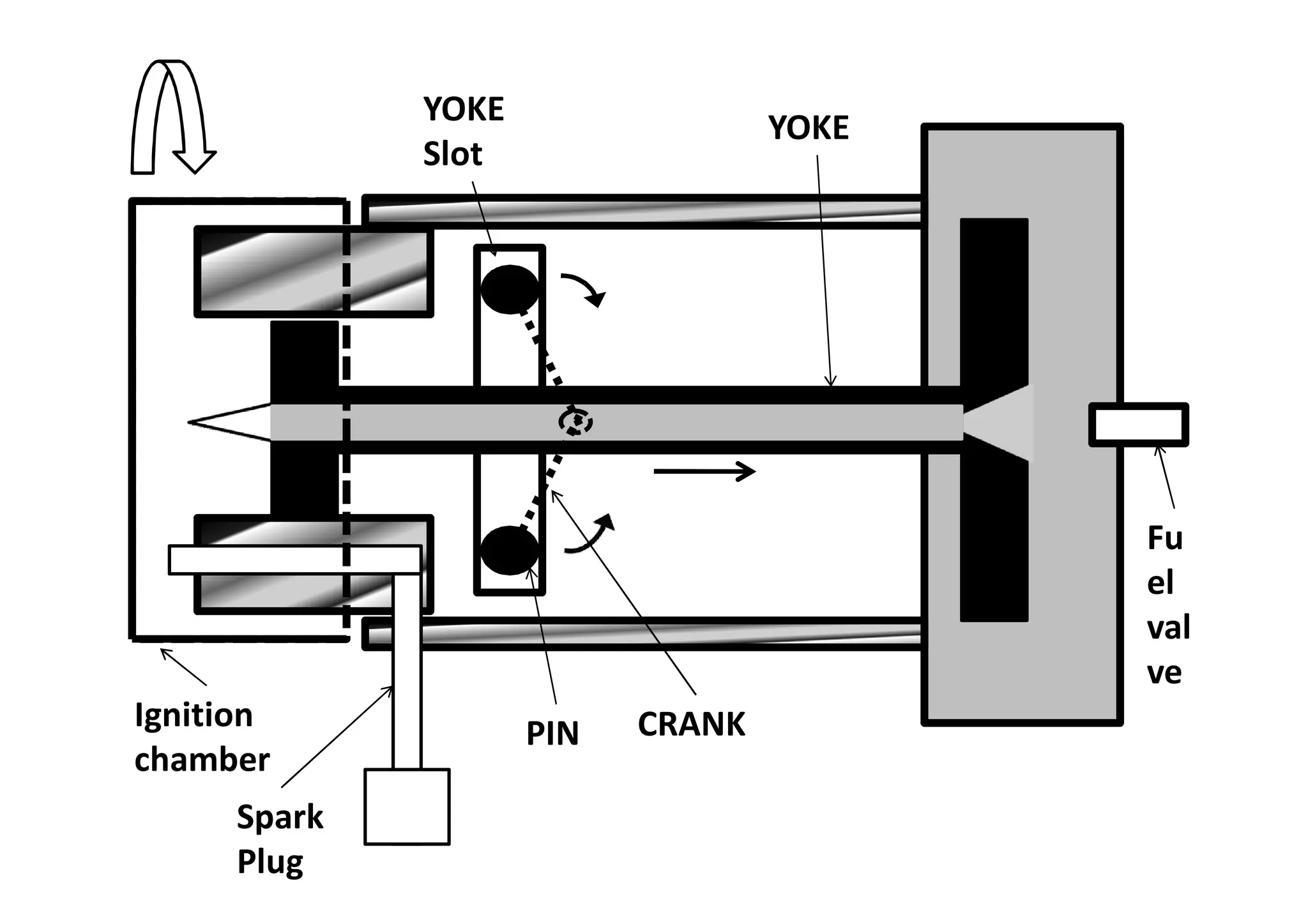

- An ignition chamber that rotates due to pressurized gas exiting transversely oriented nozzles, causing rotation powered by a coaxially mounted flywheel.

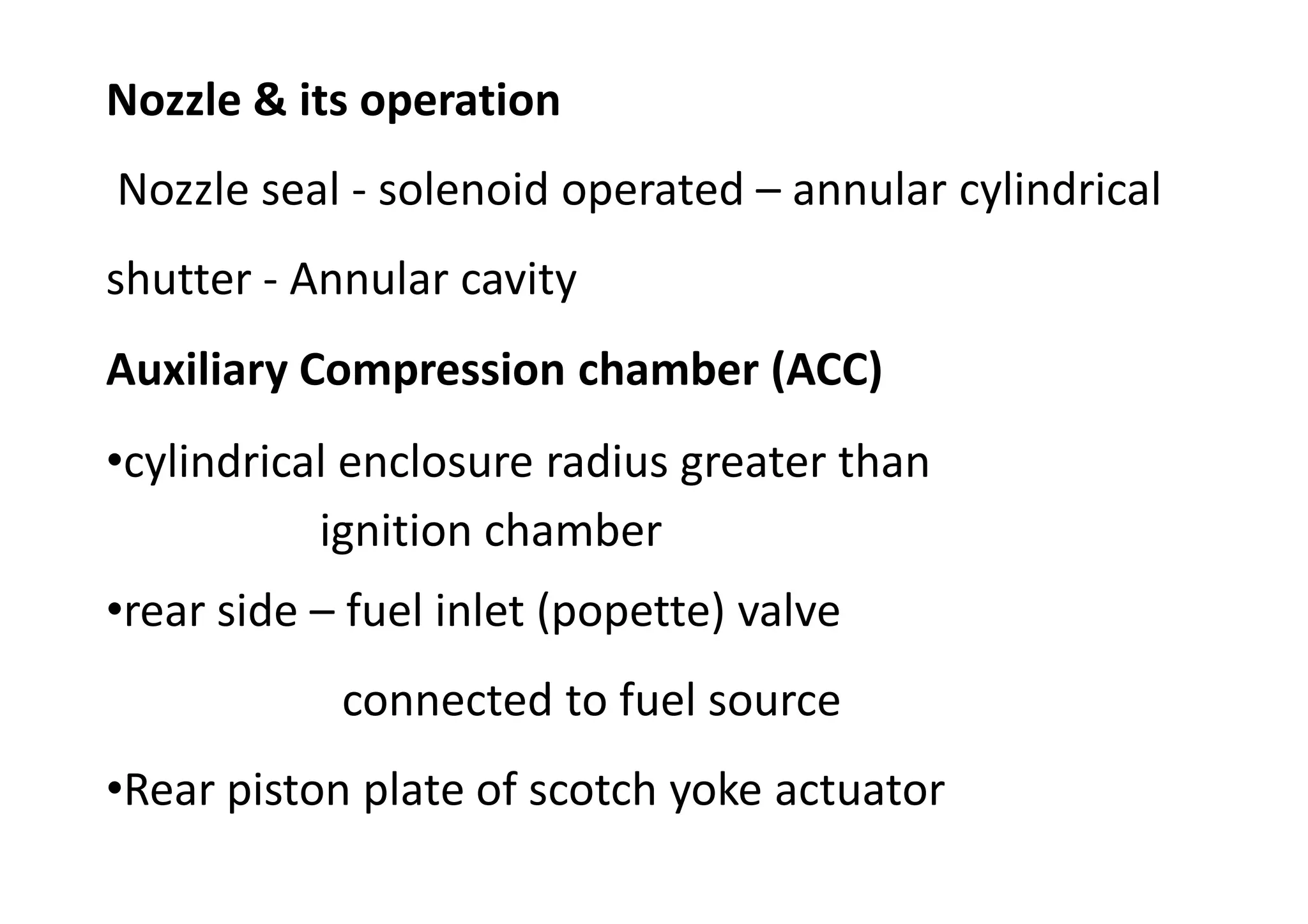

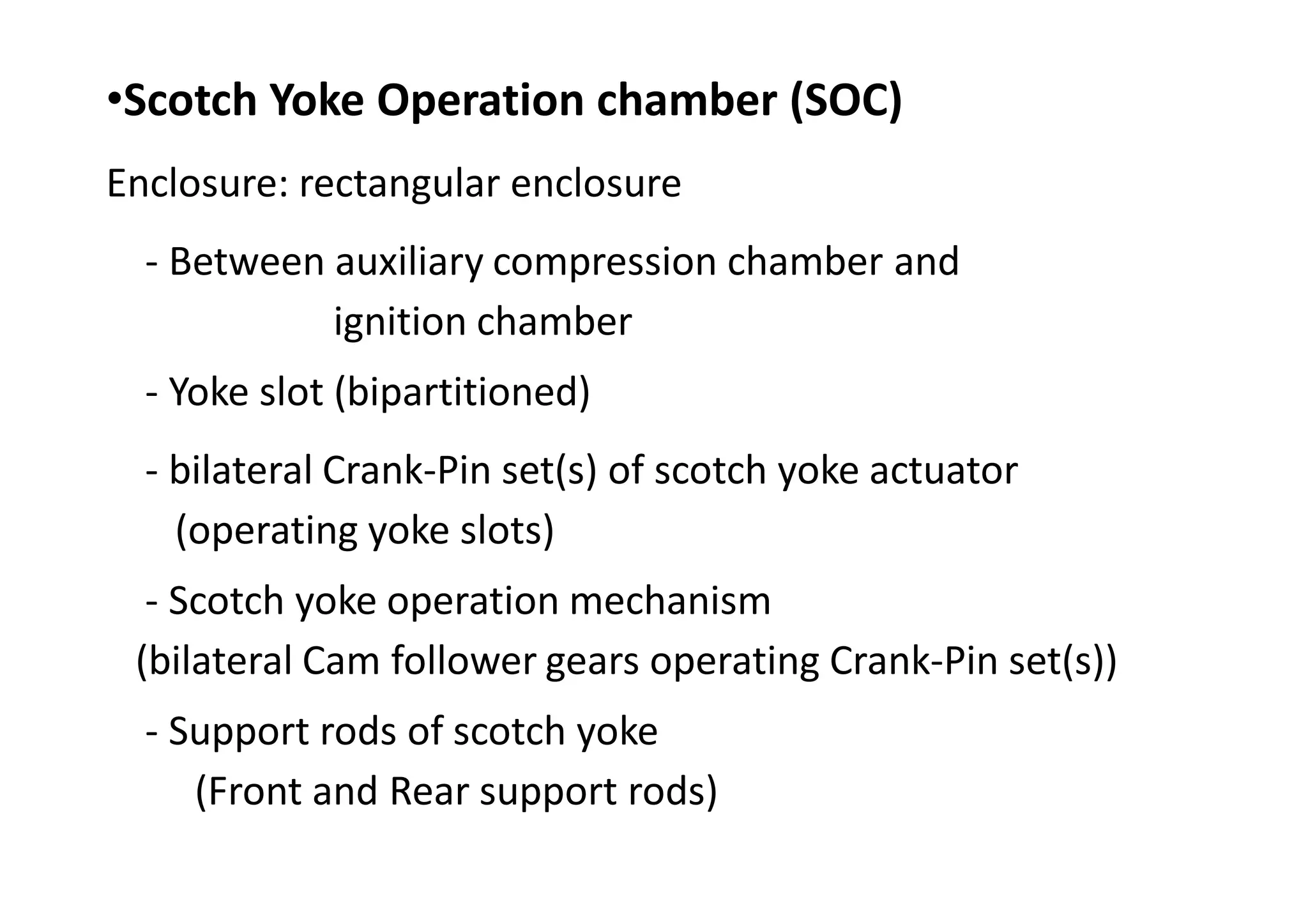

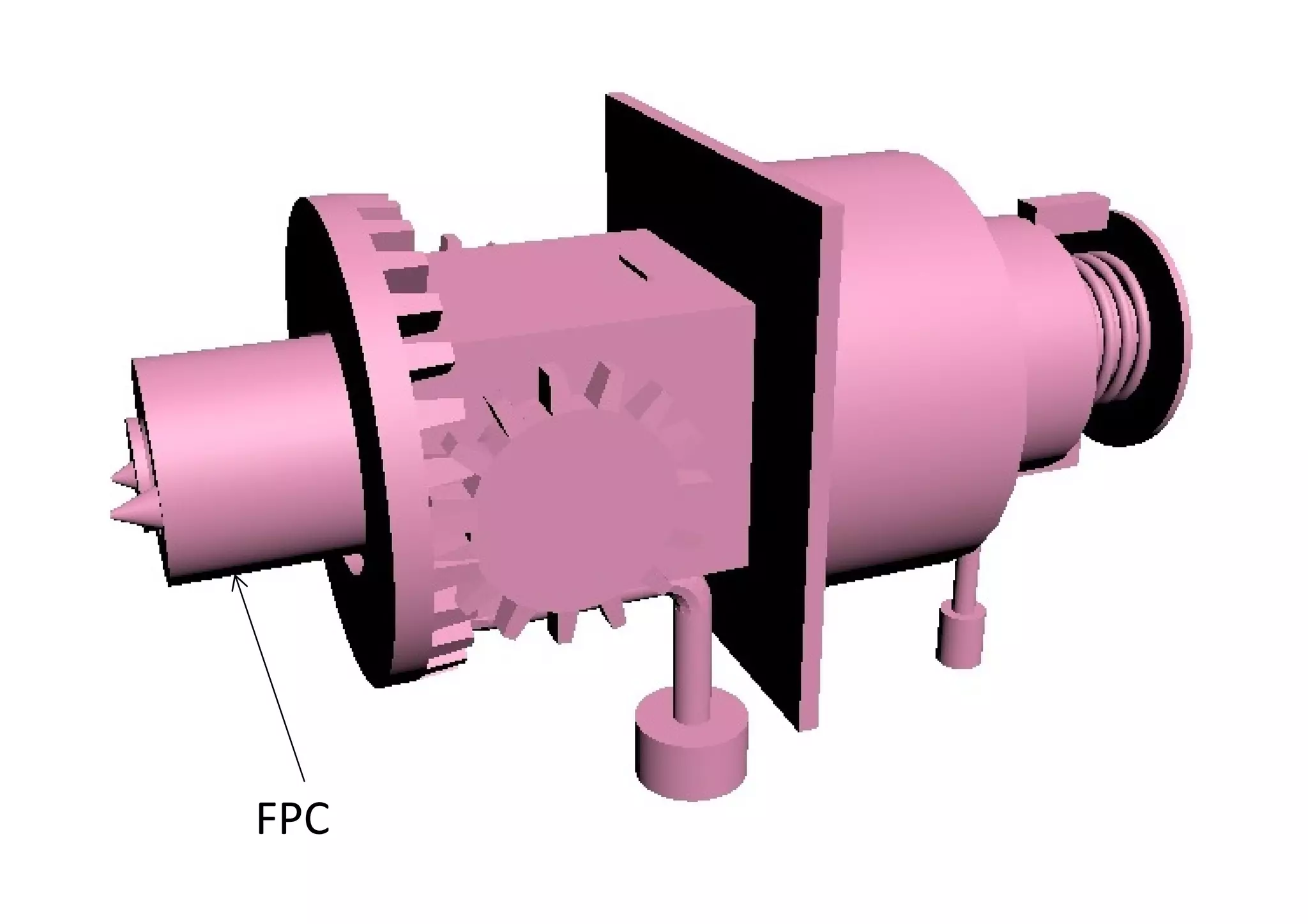

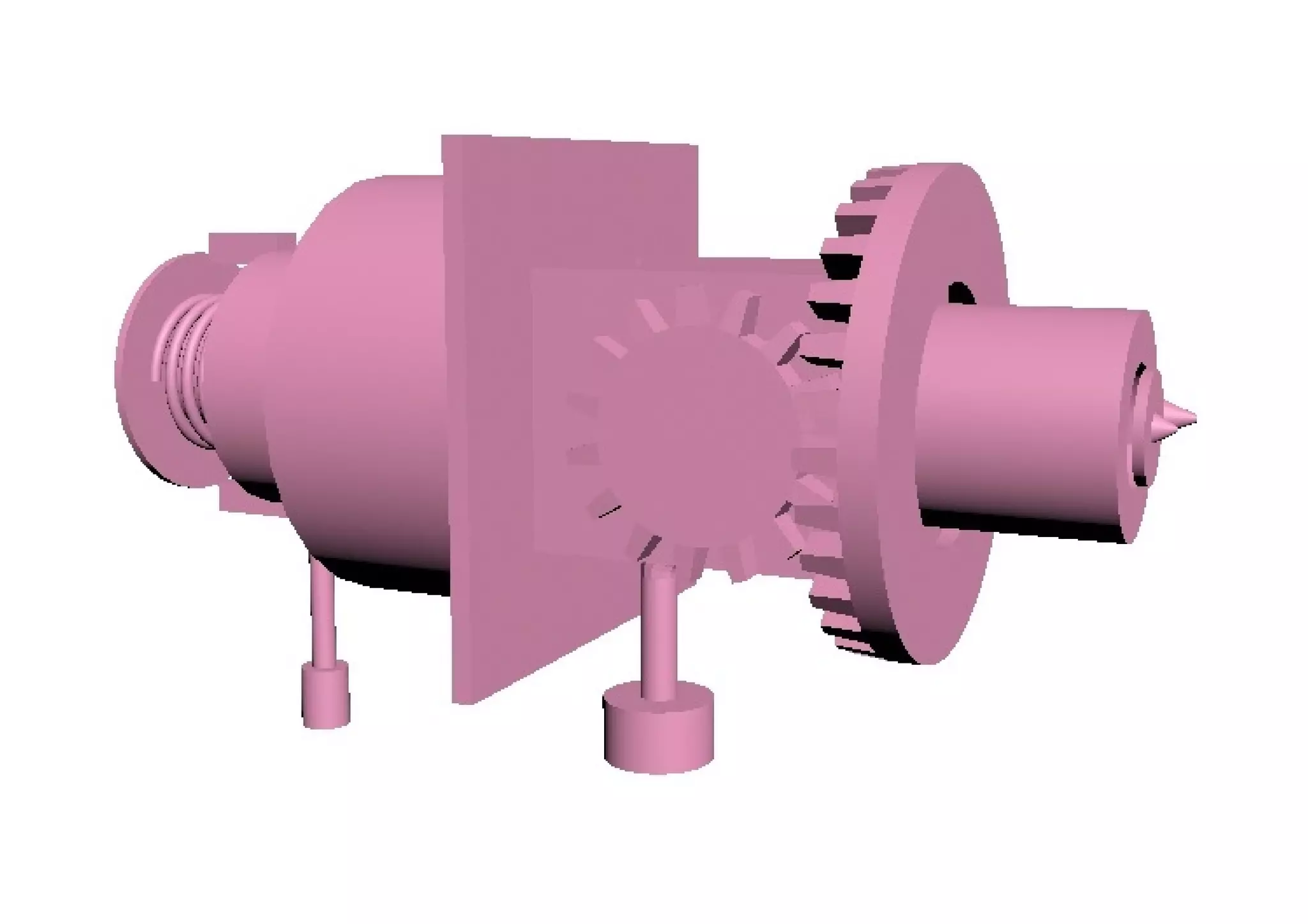

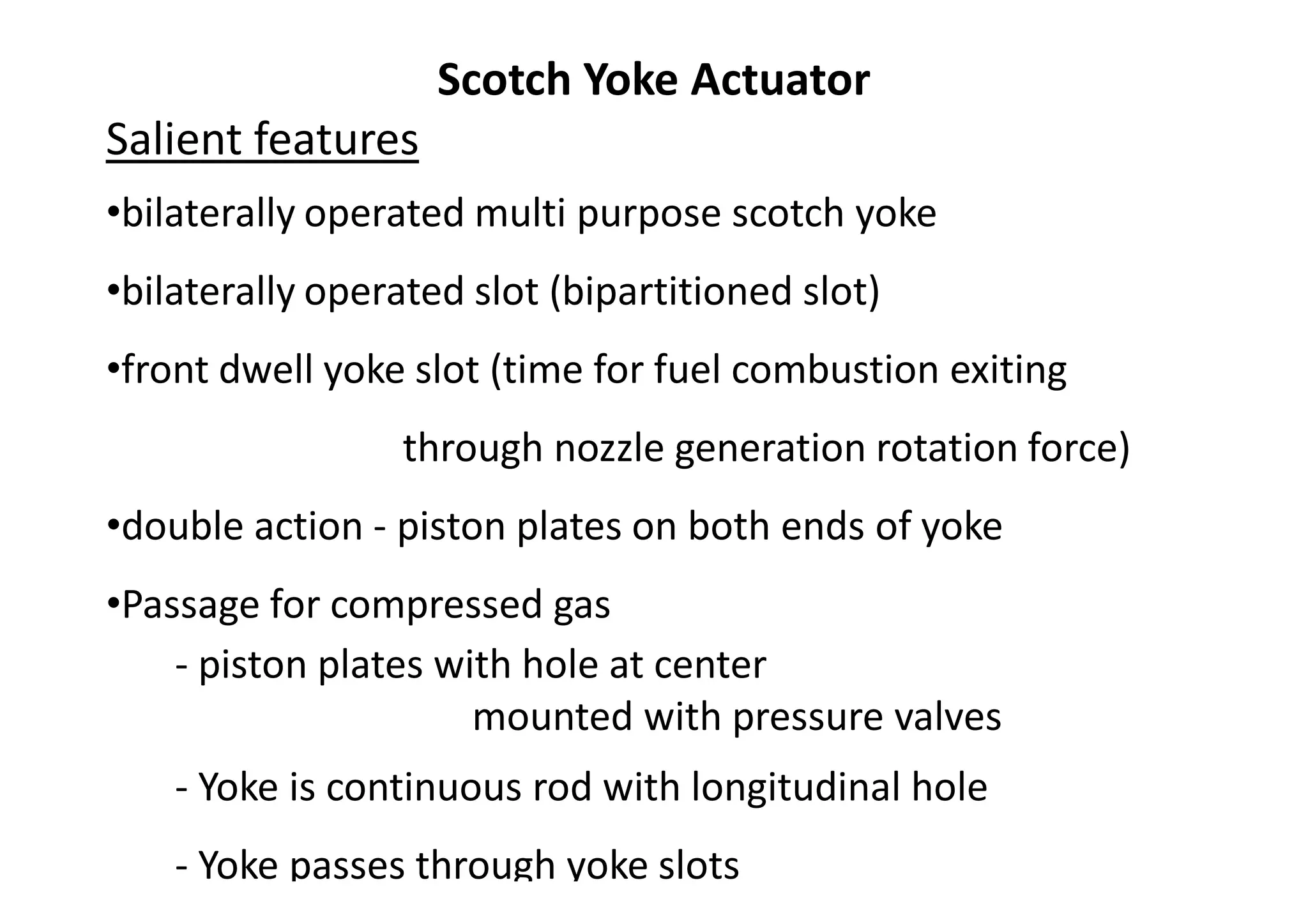

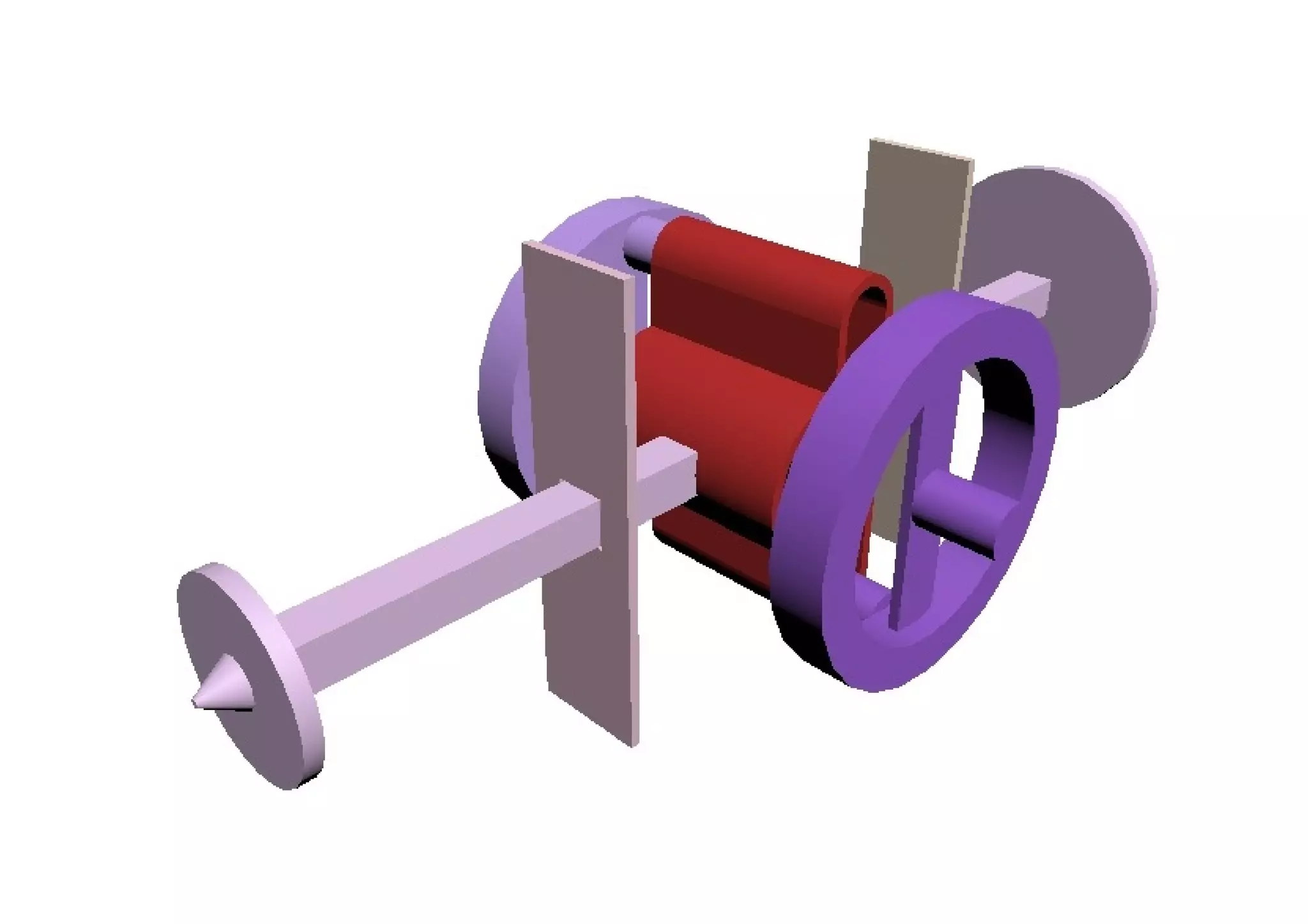

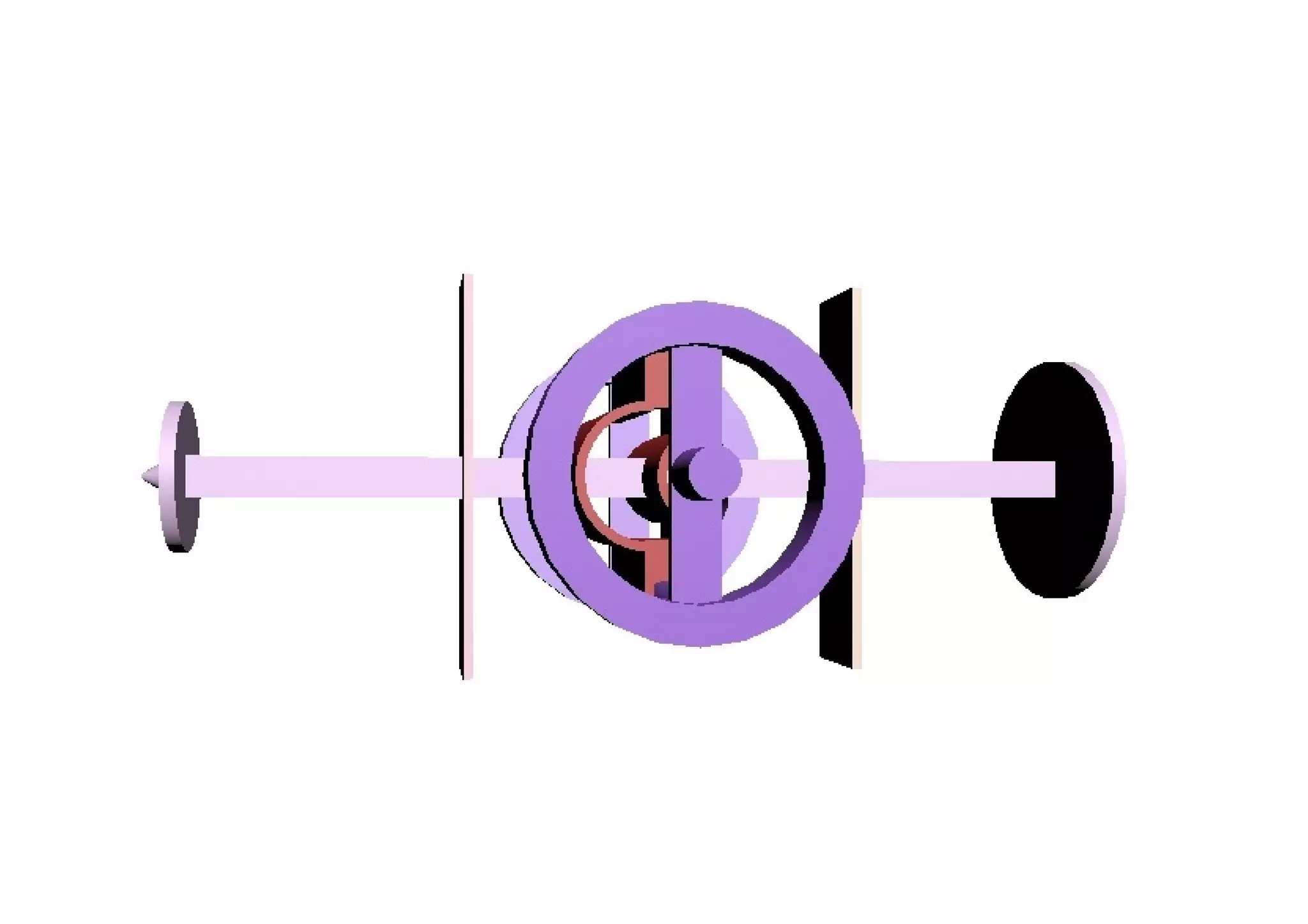

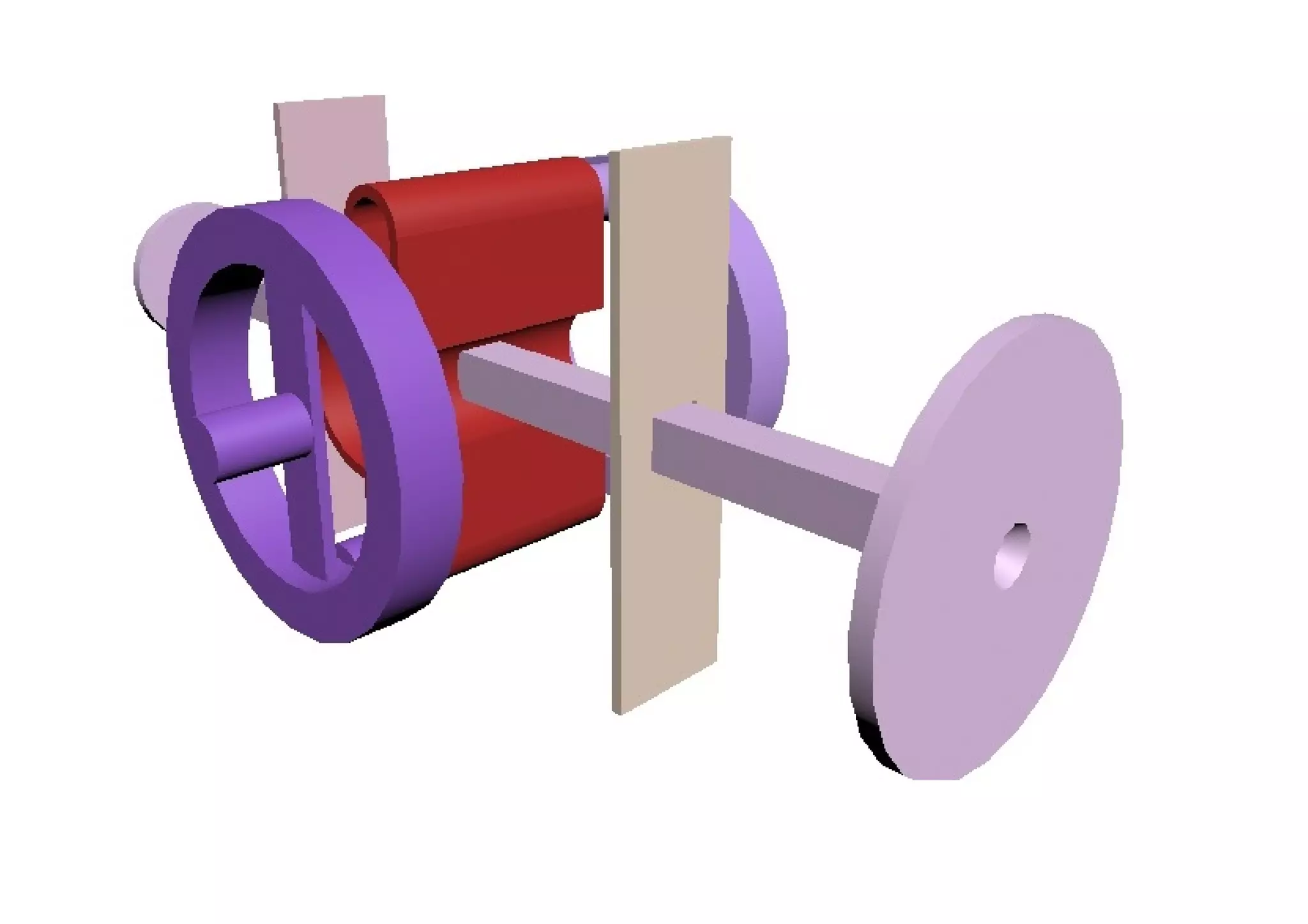

- A scotch yoke actuator that converts the rotational motion of the ignition chamber into reciprocating motion of a piston to compress fuel and deliver it into the ignition chamber.

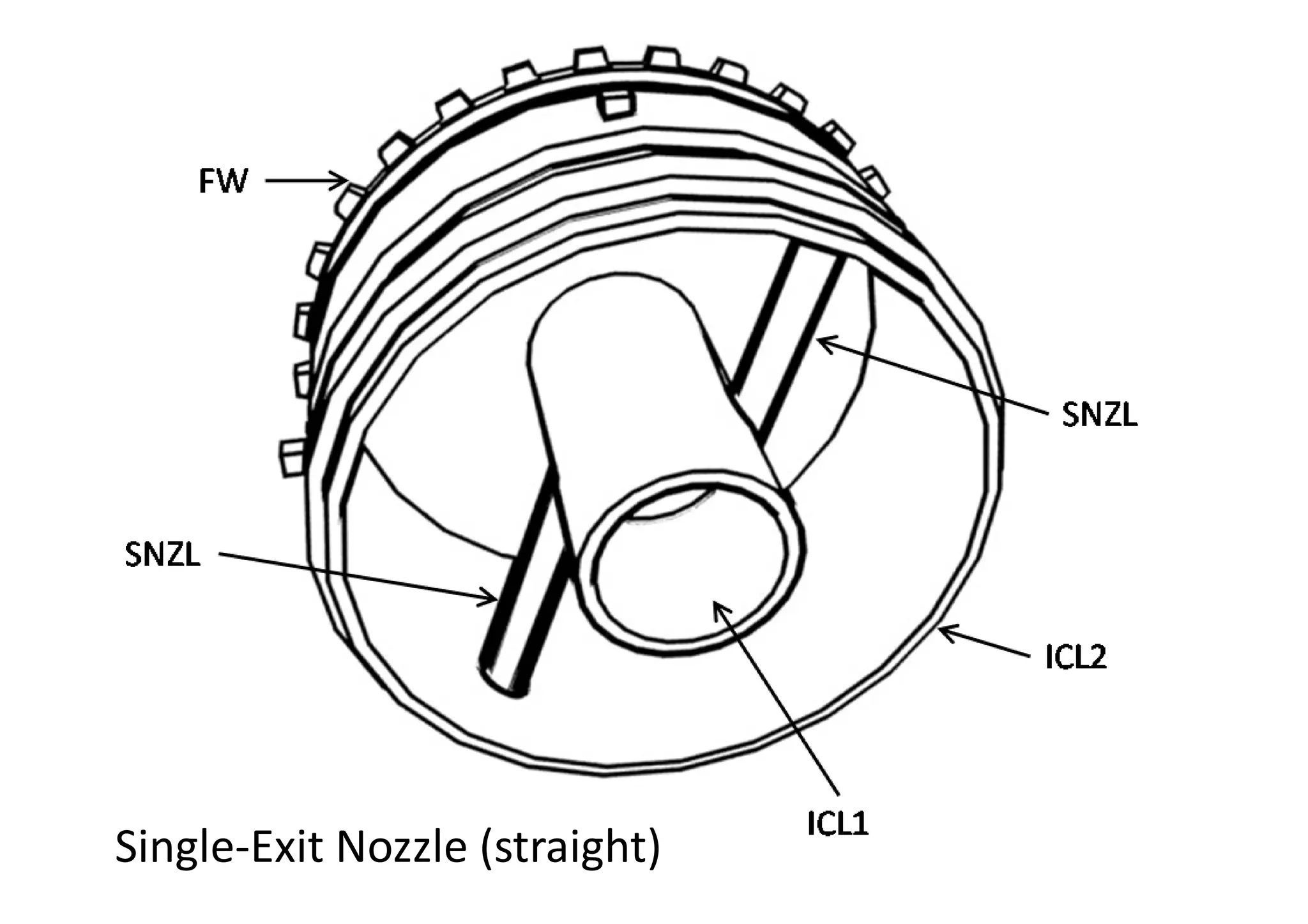

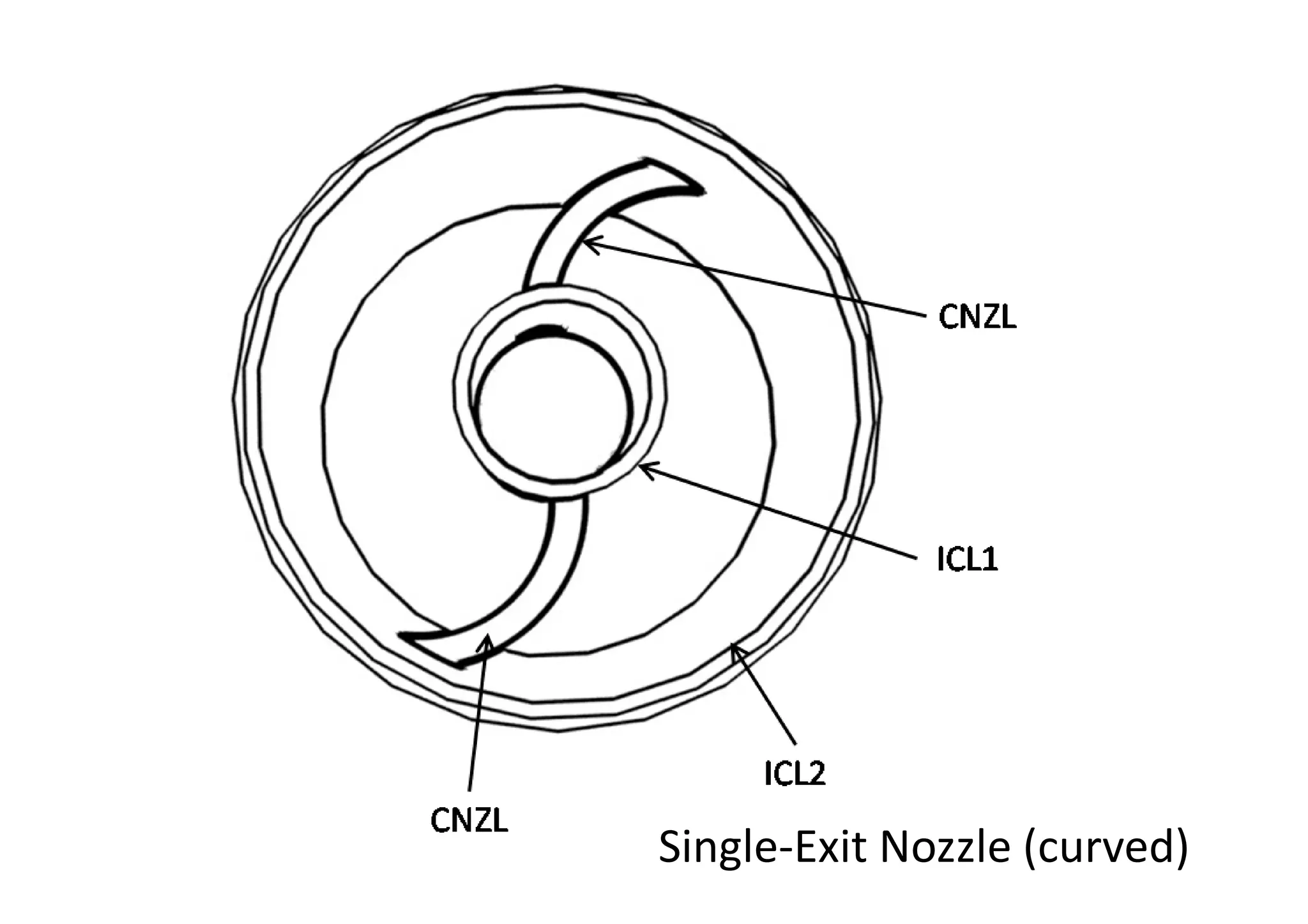

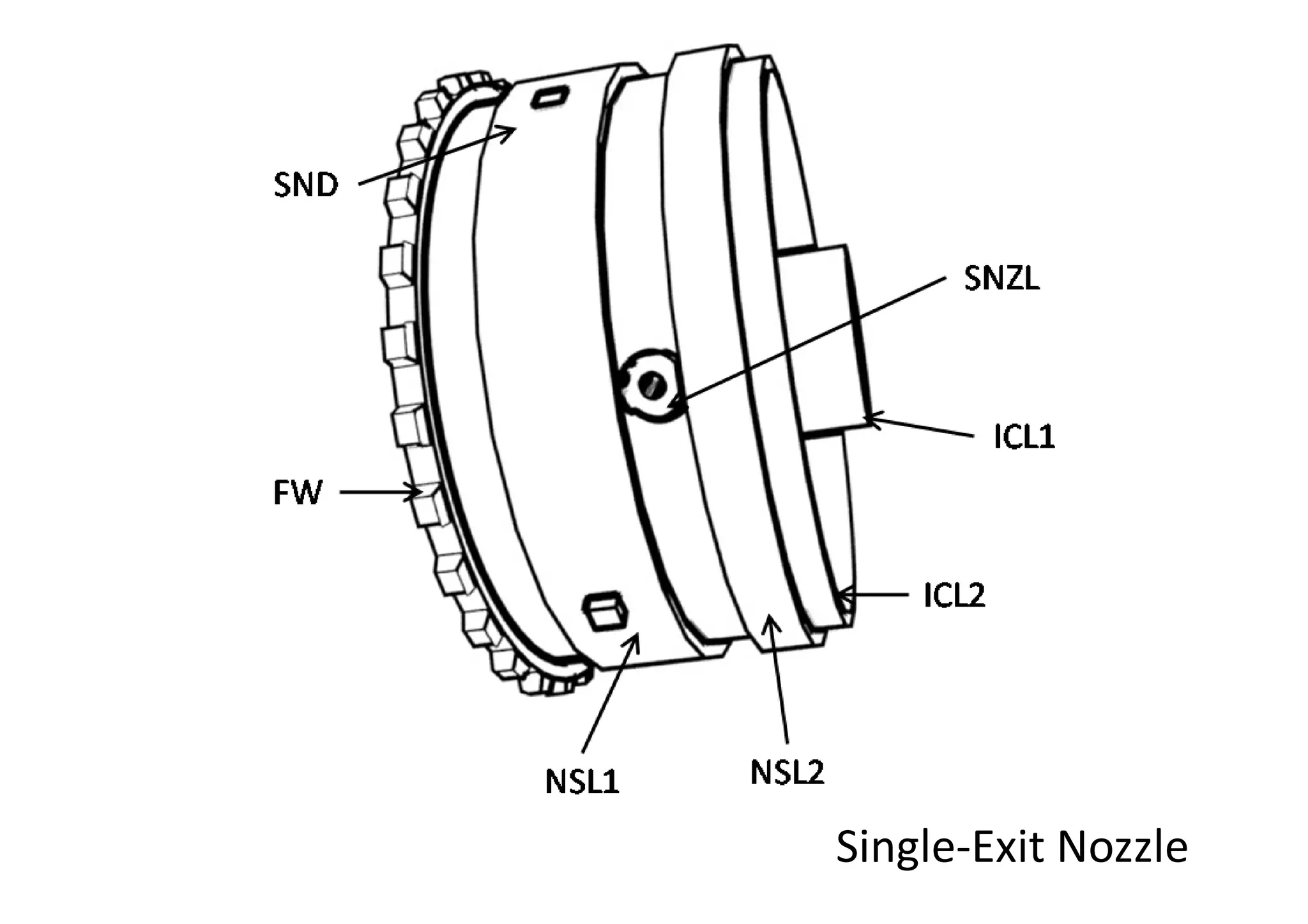

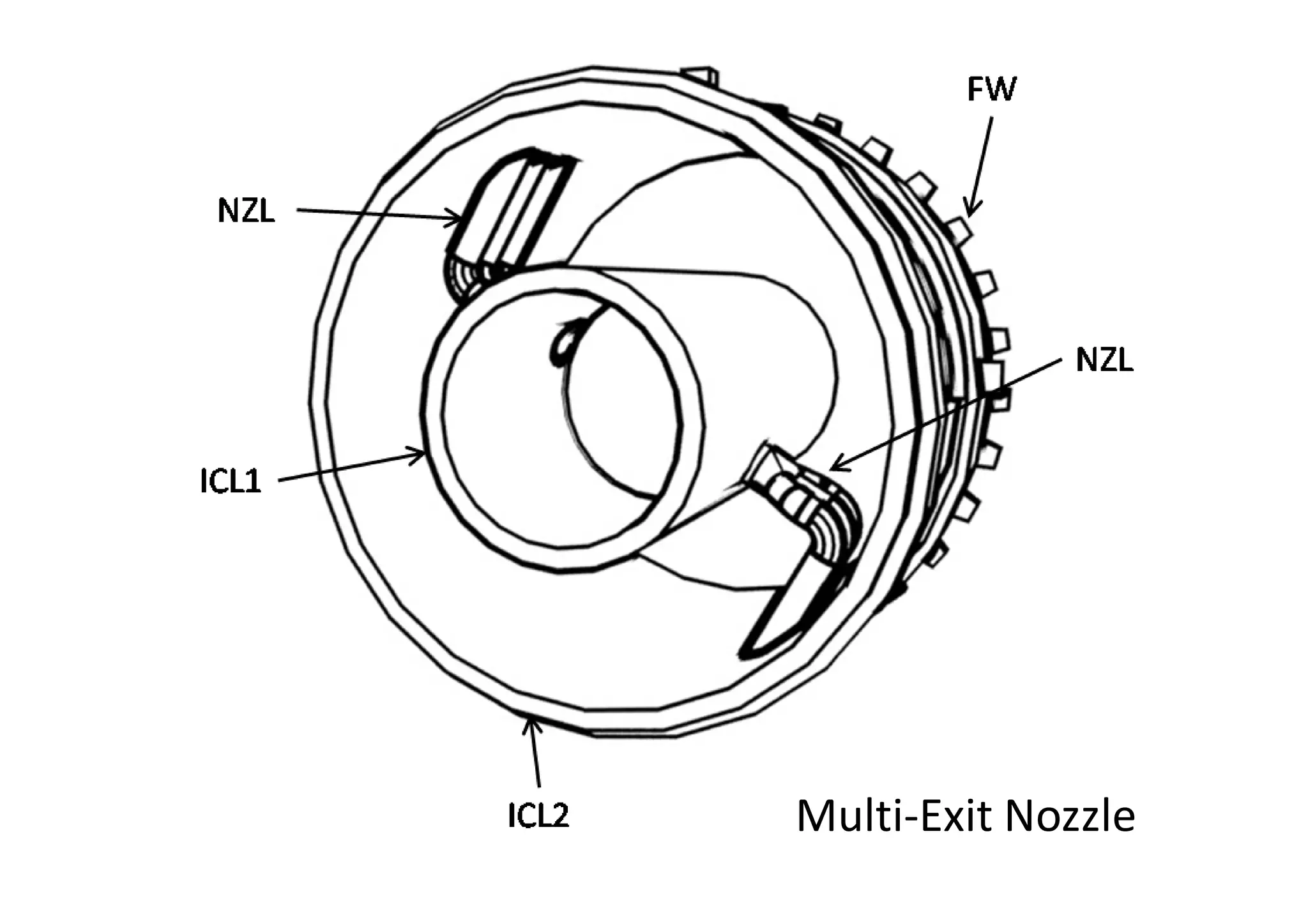

- Nozzles on the ignition chamber that open and close to control the exit of pressurized gas and maintain rotational motion, with improvements including multi-section seals and branching single exits into multiple exits.