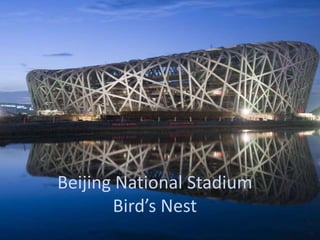

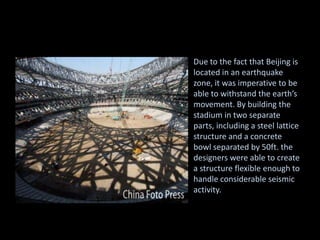

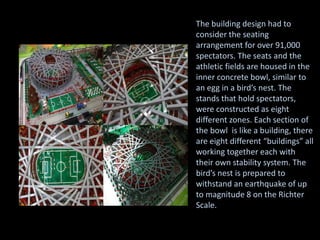

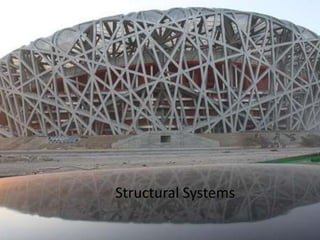

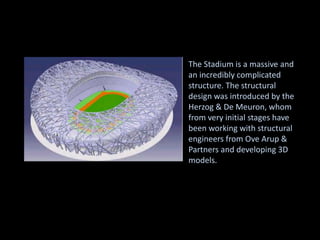

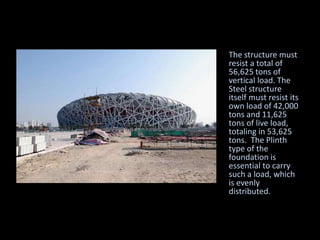

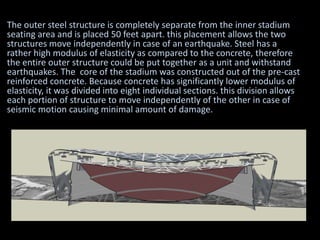

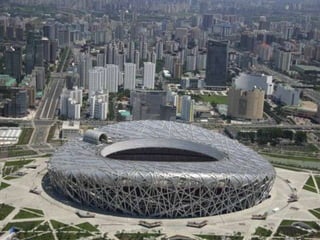

The Beijing National Stadium, also known as the Bird's Nest, is located in Beijing, China. It has three floors and is 226 feet tall. It was designed by Herzog & De Meuron and engineered by Ove Arup & Partners to withstand earthquakes up to magnitude 8. The stadium's steel lattice exterior and separate concrete interior allow the two structures to move independently during seismic activity without damaging the stadium. The Bird's Nest can seat over 91,000 spectators across its eight individual concrete seating sections.