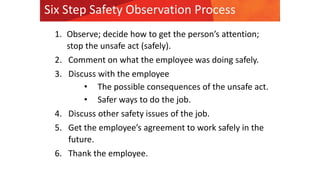

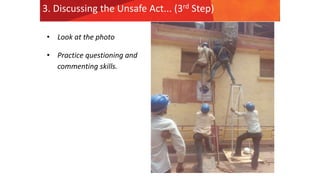

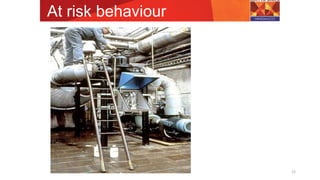

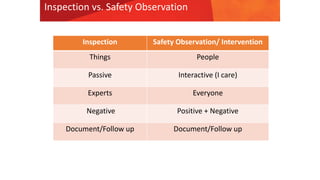

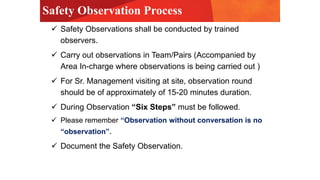

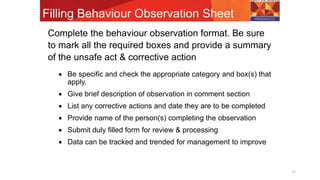

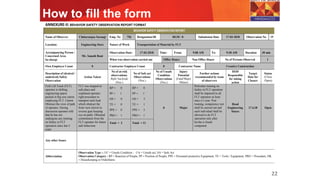

The document outlines a structured six-step behavior-based safety (BBS) observation process aimed at improving workplace safety through proactive engagement and communication with employees. It emphasizes the importance of observing unsafe behaviors, providing constructive feedback, discussing safety concerns, and collaboratively developing safer work practices. The guide also includes information on documenting observations and evaluating safety performance to enhance an organization's overall safety culture.