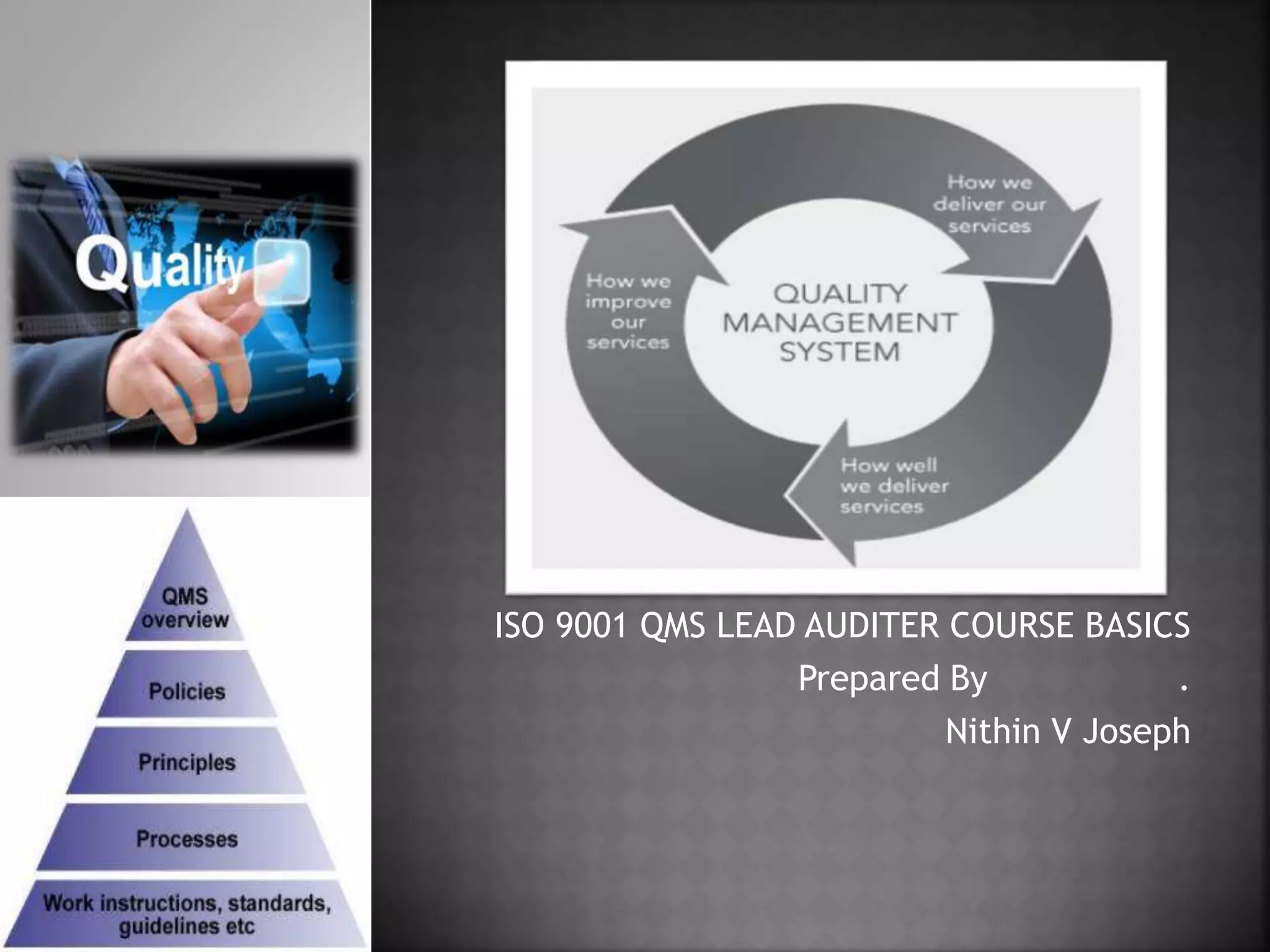

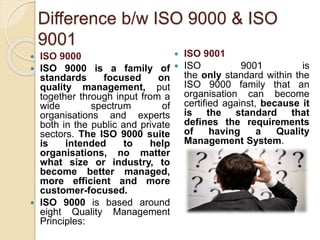

The document discusses the basics of ISO 9001 quality management systems. It describes the Plan-Do-Check-Act (PDCA) cycle, also known as the Deming cycle or Shewhart cycle. PDCA involves planning improvements, implementing them, checking results, and acting to make further adjustments. The document also discusses the relationship between quality management and customer satisfaction, defining key terms like quality management systems, processes, ISO 9000, and ISO 9001. It explains that ISO 9001 defines requirements for a quality management system to meet customer and regulatory requirements.