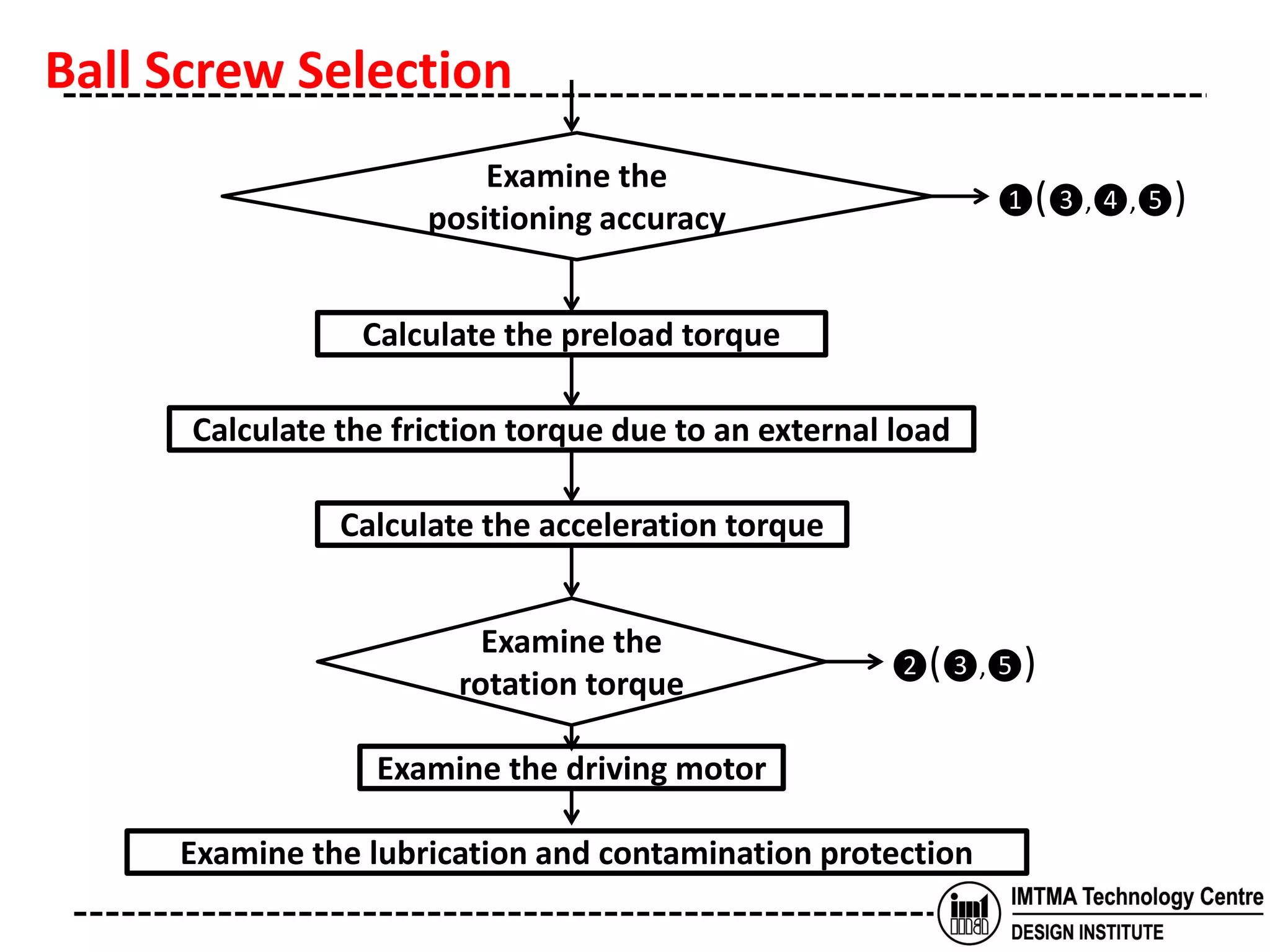

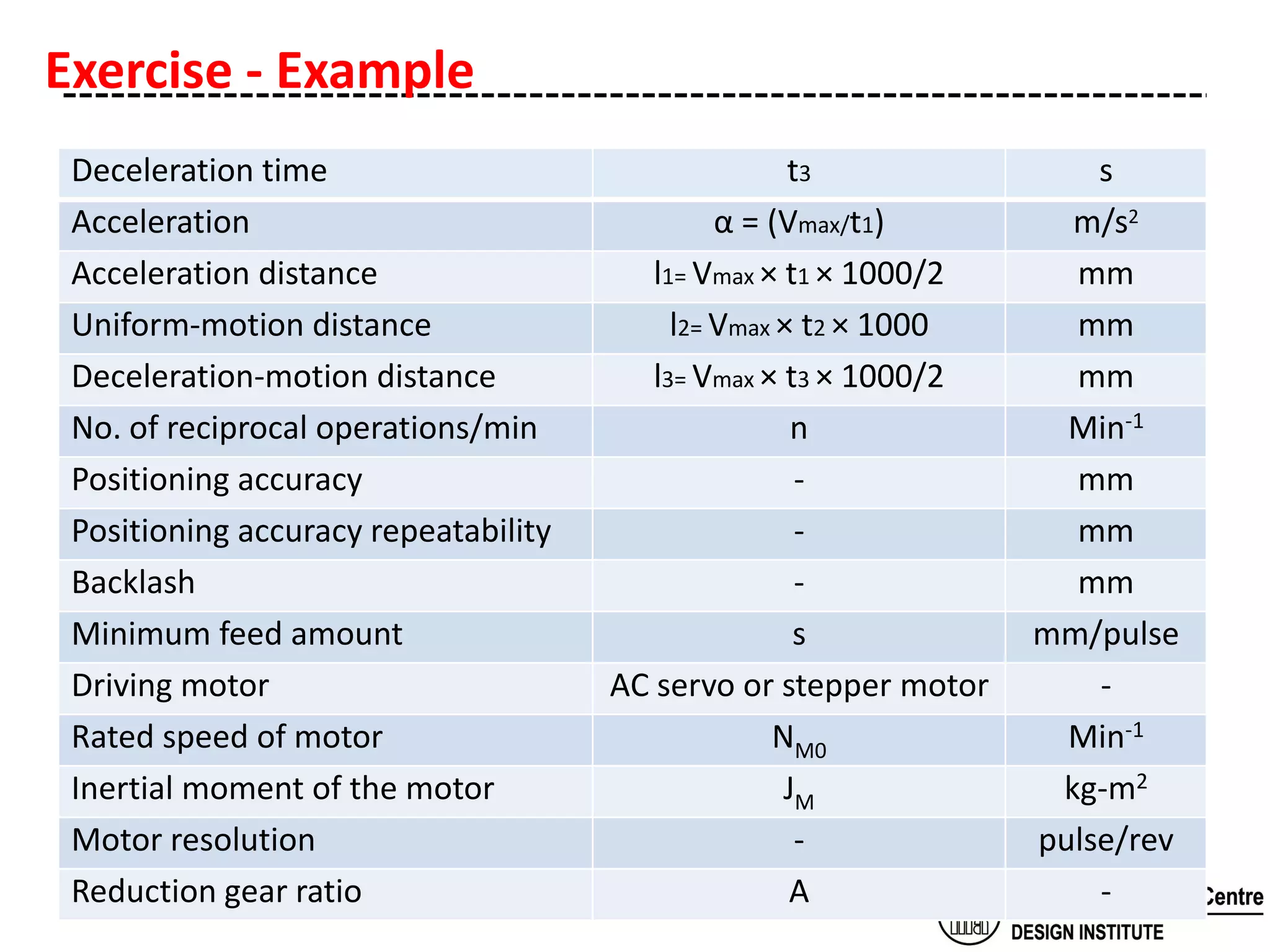

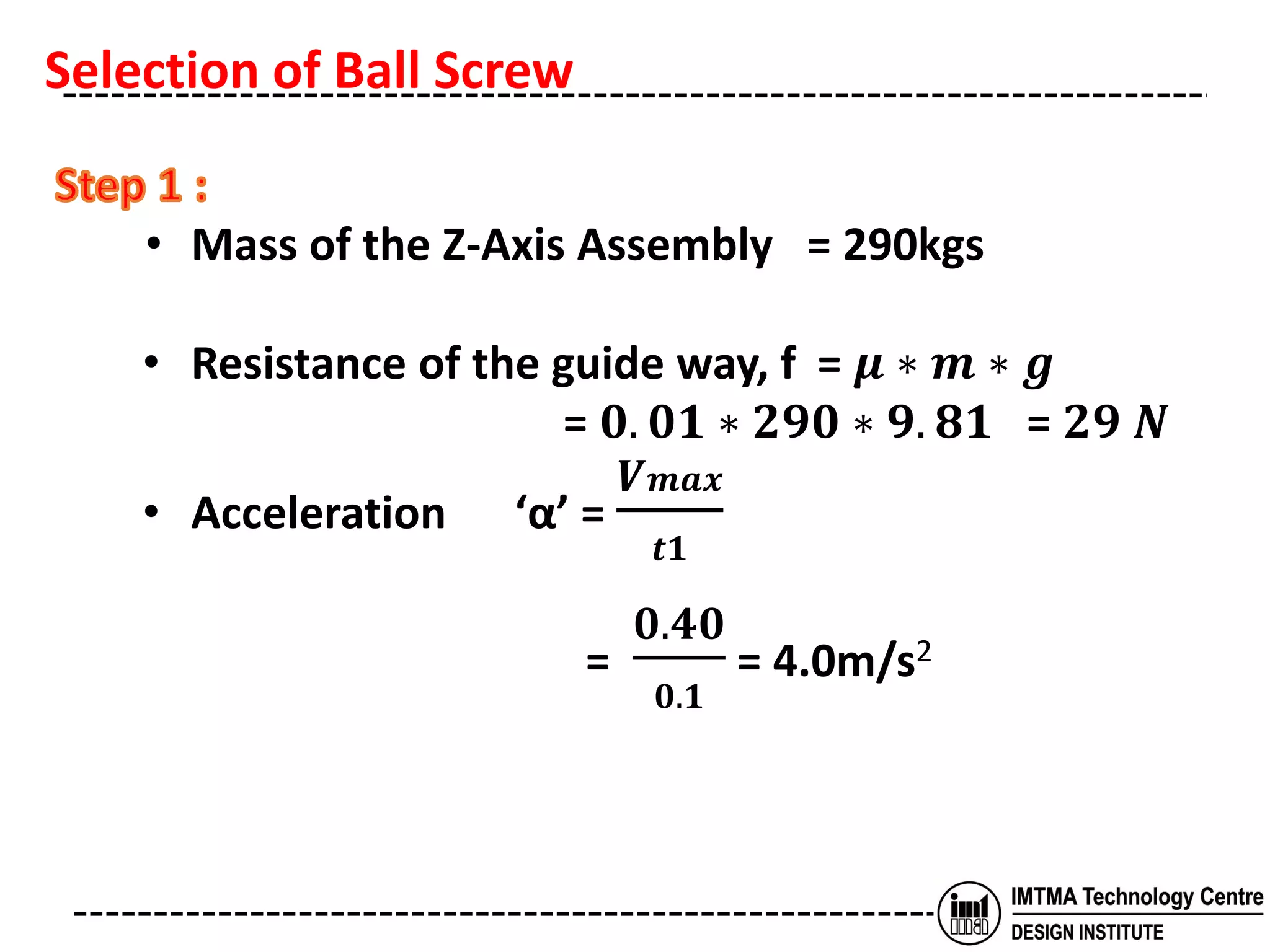

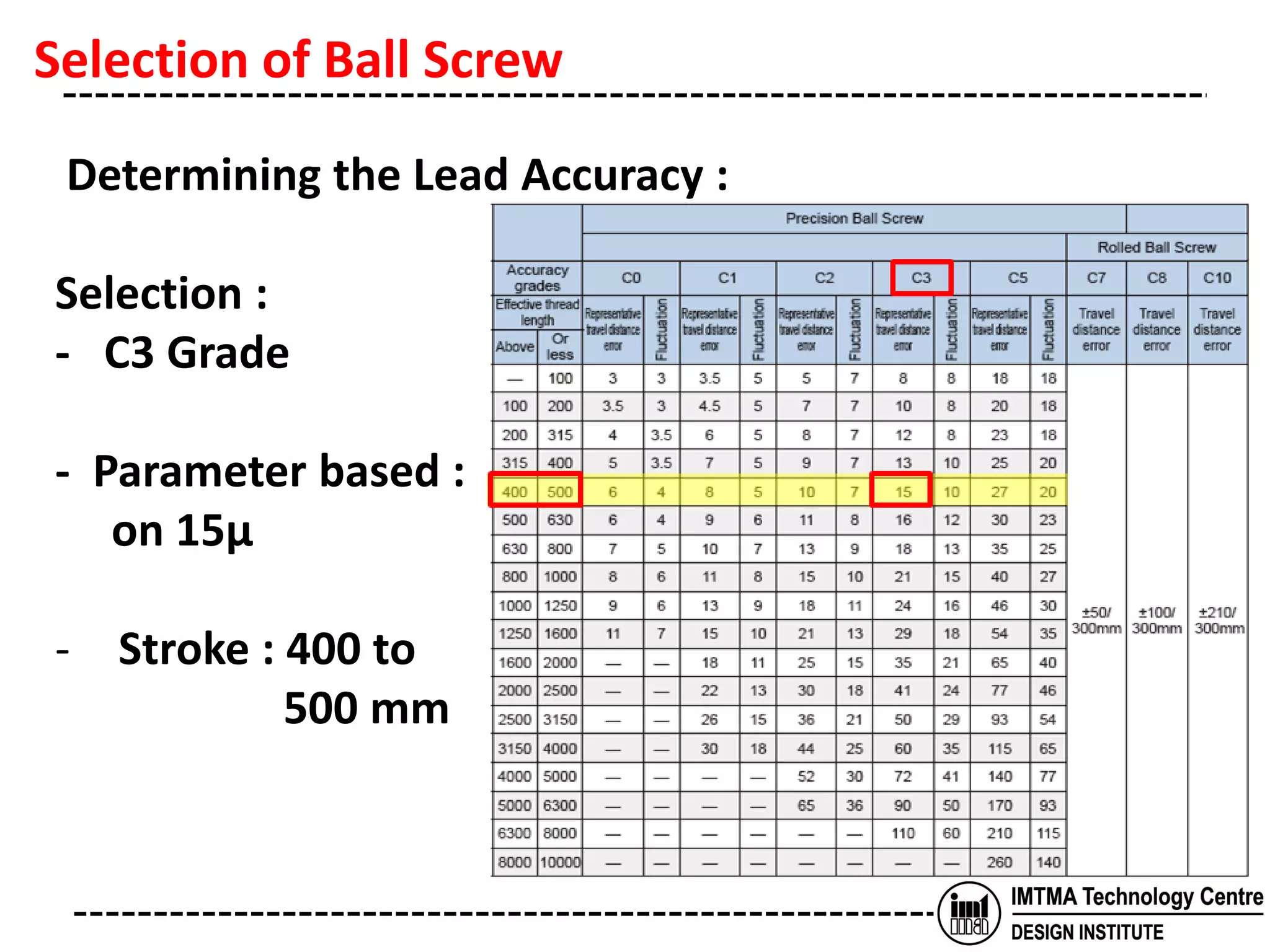

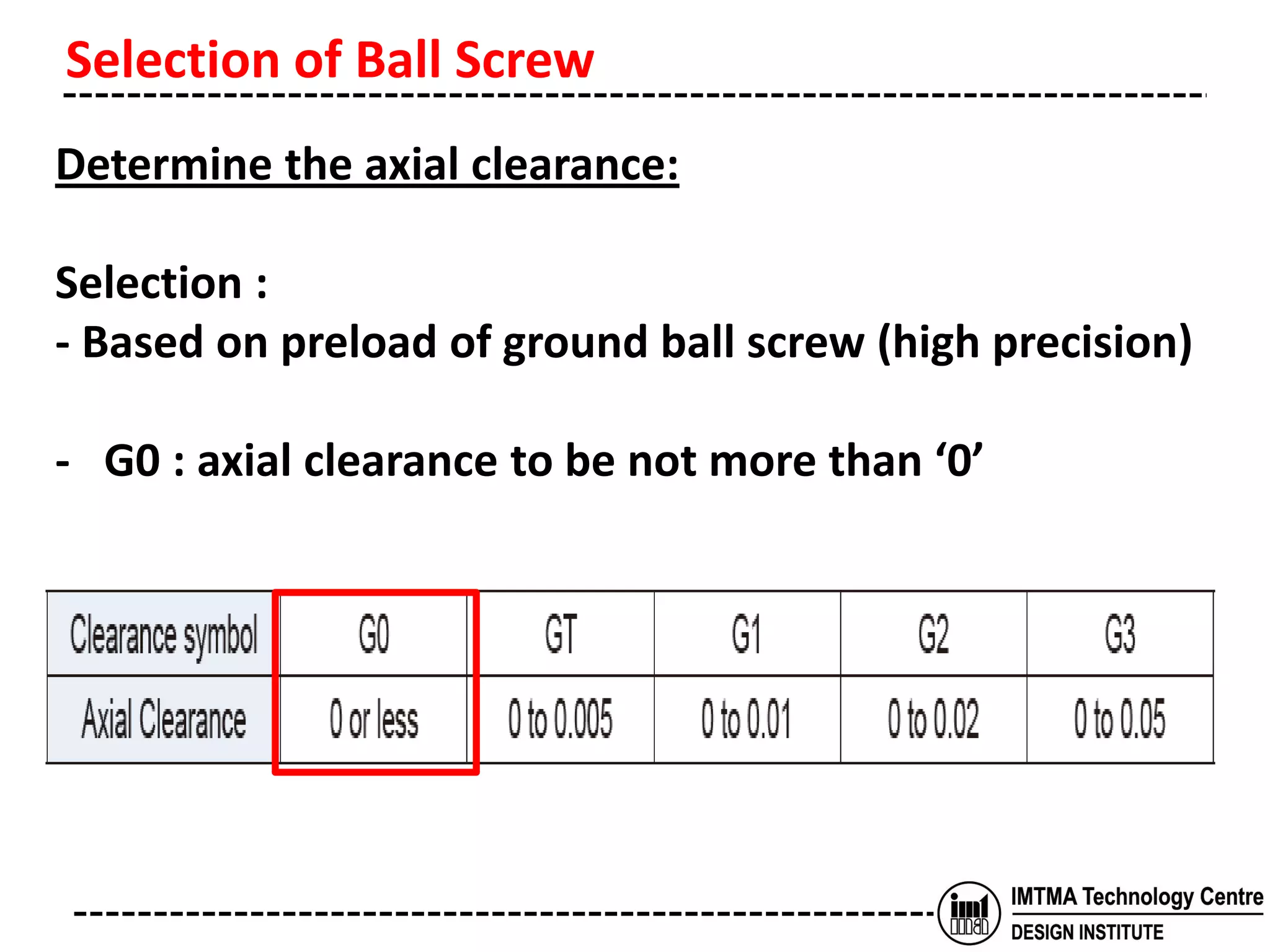

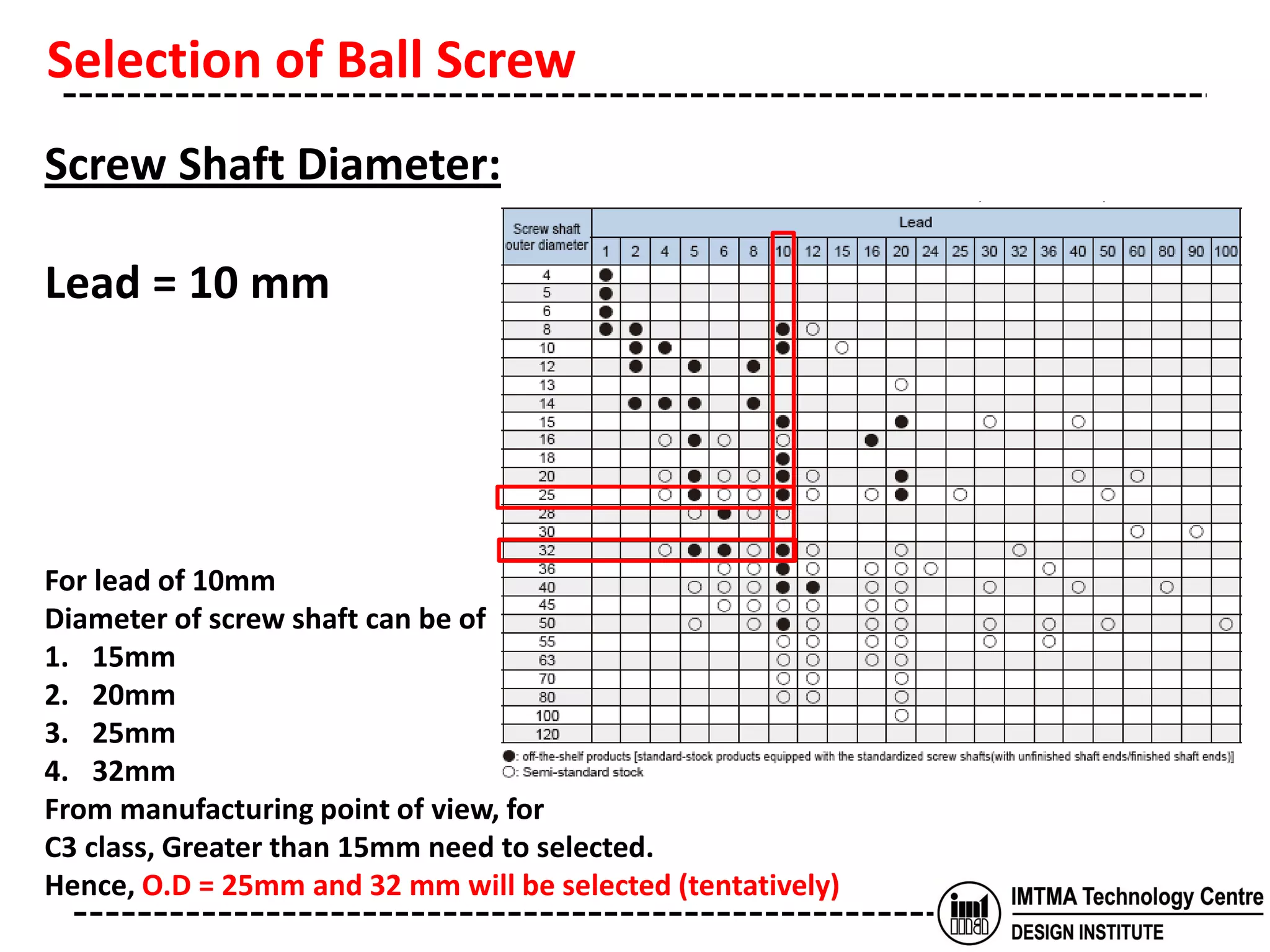

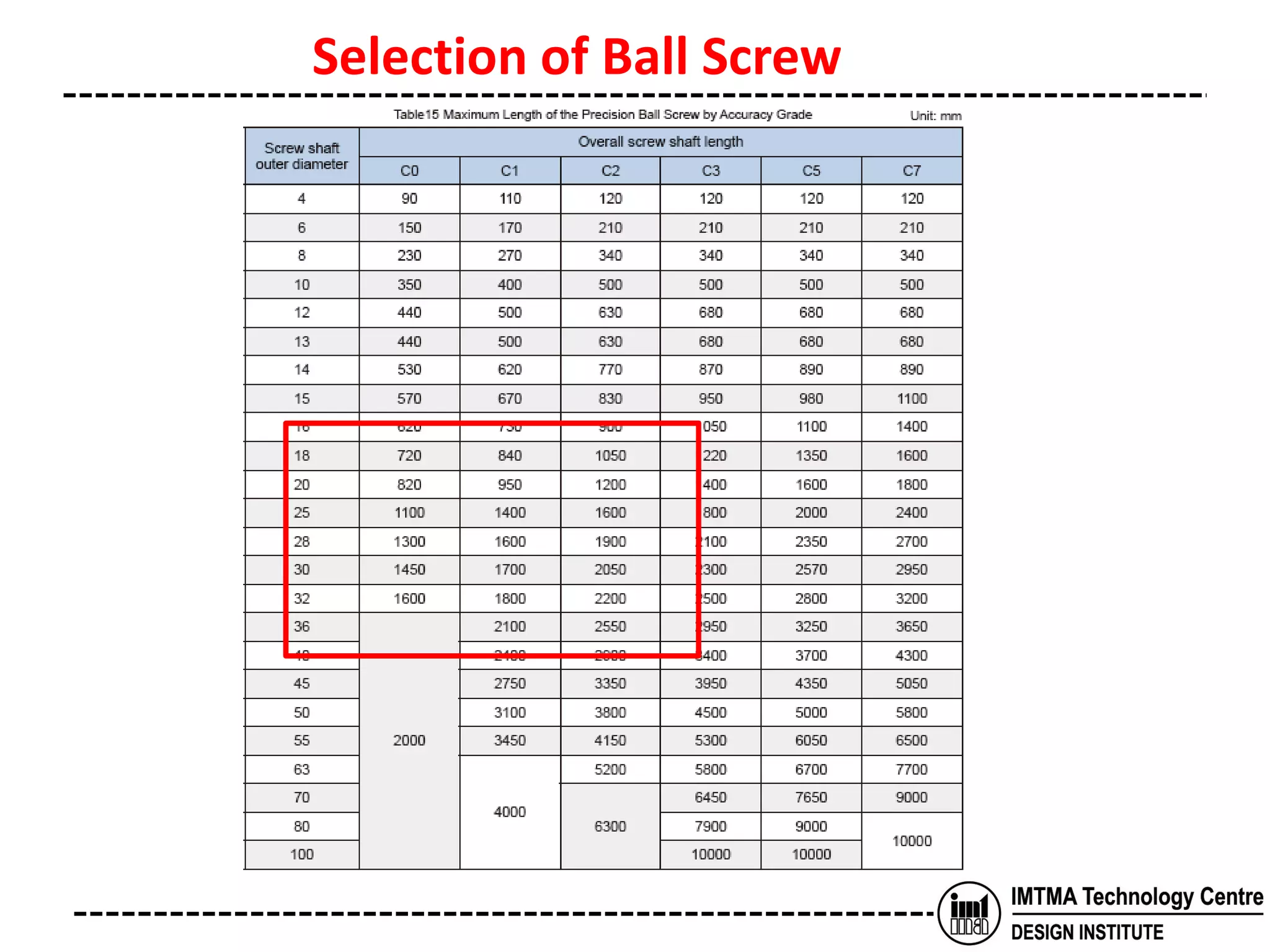

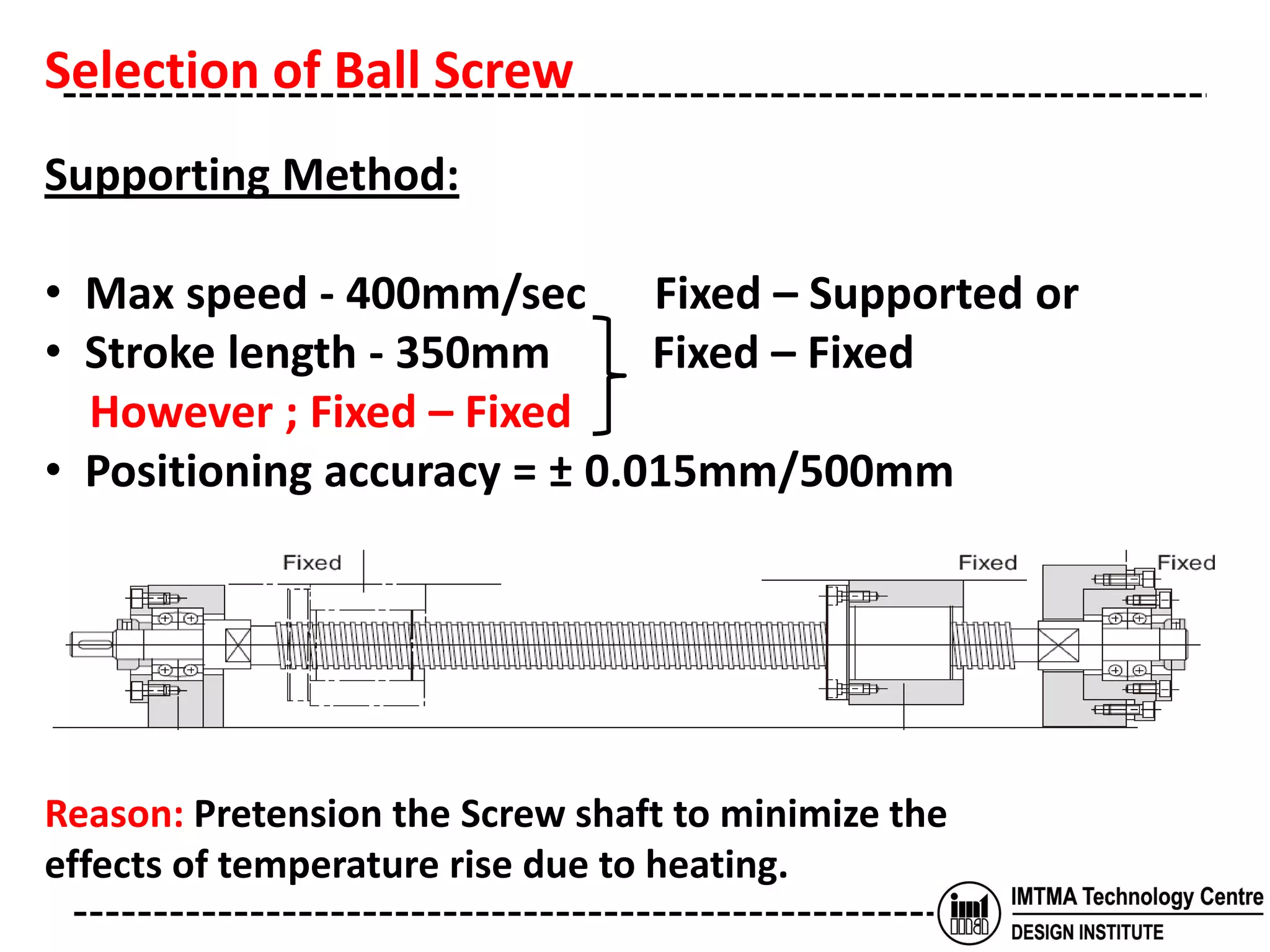

The document discusses the selection of a ball screw for a machine tool based on its operating conditions and design specifications. It outlines the steps to determine the key parameters for the ball screw like lead accuracy, axial clearance, screw length and diameter, support method, permissible axial load and rotational speed, nut model, rigidity, positioning accuracy, torques required, and motor specifications. An example selection process is provided based on the given design data and machine specifications for a lathe machine. Key factors like buckling load, tensile strength and critical speeds are examined to ensure safe design of the ball screw.