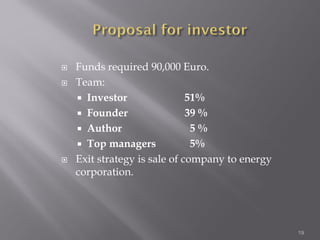

The document outlines a project for developing a high-efficiency heat generator using hydrogen dissociation and recombination, targeting home and industrial heating markets. The technology is projected to capture a significant share of a €15 billion market, with the potential for €165 million in sales by 2016. Key features include a unique method of heat generation with high efficiency, collaboration with industrial partners for production, and an exit strategy via sale to an energy corporation.