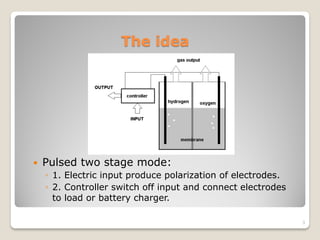

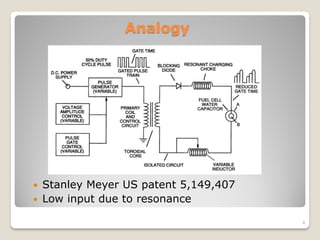

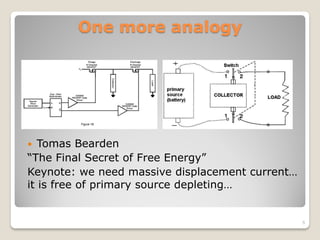

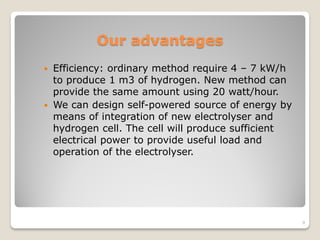

The document proposes a high-efficiency electrolyzer that uses a pulsed two-stage process to dissociate water with minimal energy input. In the first stage, an electric input polarizes the electrodes. In the second stage, the input is switched off and the polarized electrodes are connected to a load or battery charger. It is claimed this process could produce 1 cubic meter of hydrogen using only 20 watt-hours, much less than conventional electrolyzers. The inventor seeks funding to build a prototype and test the design with industrial partners, with the goal of eventually mass producing and licensing the technology.