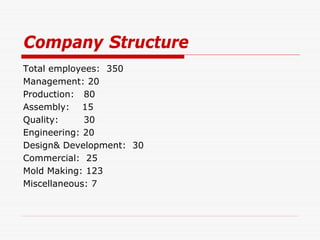

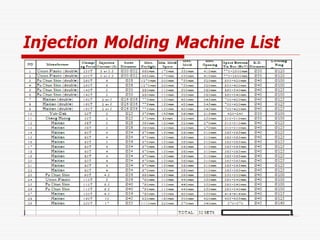

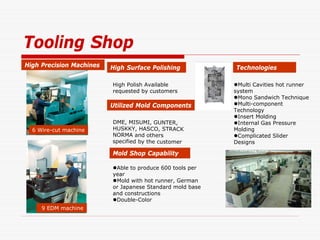

Shenzhen Sapac Industry Co., Ltd is a precision plastic injection molding company founded in 2003 with 350 employees. They specialize in automotive parts and have 50 injection molding machines and a tooling shop with 45 machines. They provide design, prototyping, molding, assembly, and logistics services. Their customers include automotive suppliers such as Delphi, Valeo, and Magnet.