The document provides technical specifications for several CAD/CAM systems:

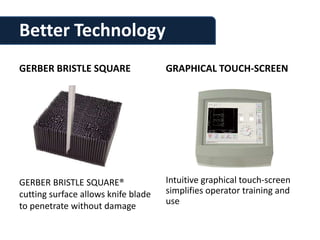

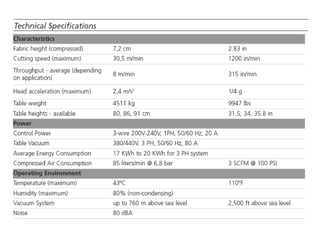

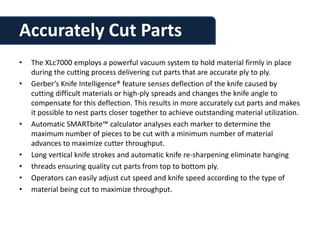

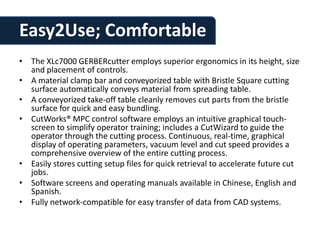

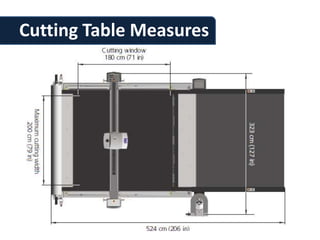

The GERBER XLc7000 can cut materials up to 7.2 cm thick and 2 meters wide, with features like a bristle cutting surface, touchscreen interface, and vacuum system to hold materials firmly.

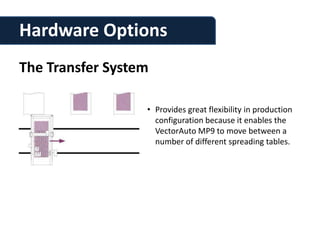

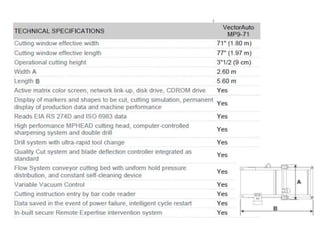

The Lectra VectorAuto MP9 can cut materials up to 9 cm thick and is suited for automotive interior parts, with an intuitive interface, variable vacuum, and software to guide operators.

The Investronica Diamond has a 70 mm cutting height, automatic material conveyance, digital control unit, and balanced knife technology to accurately cut difficult fabrics like denim.