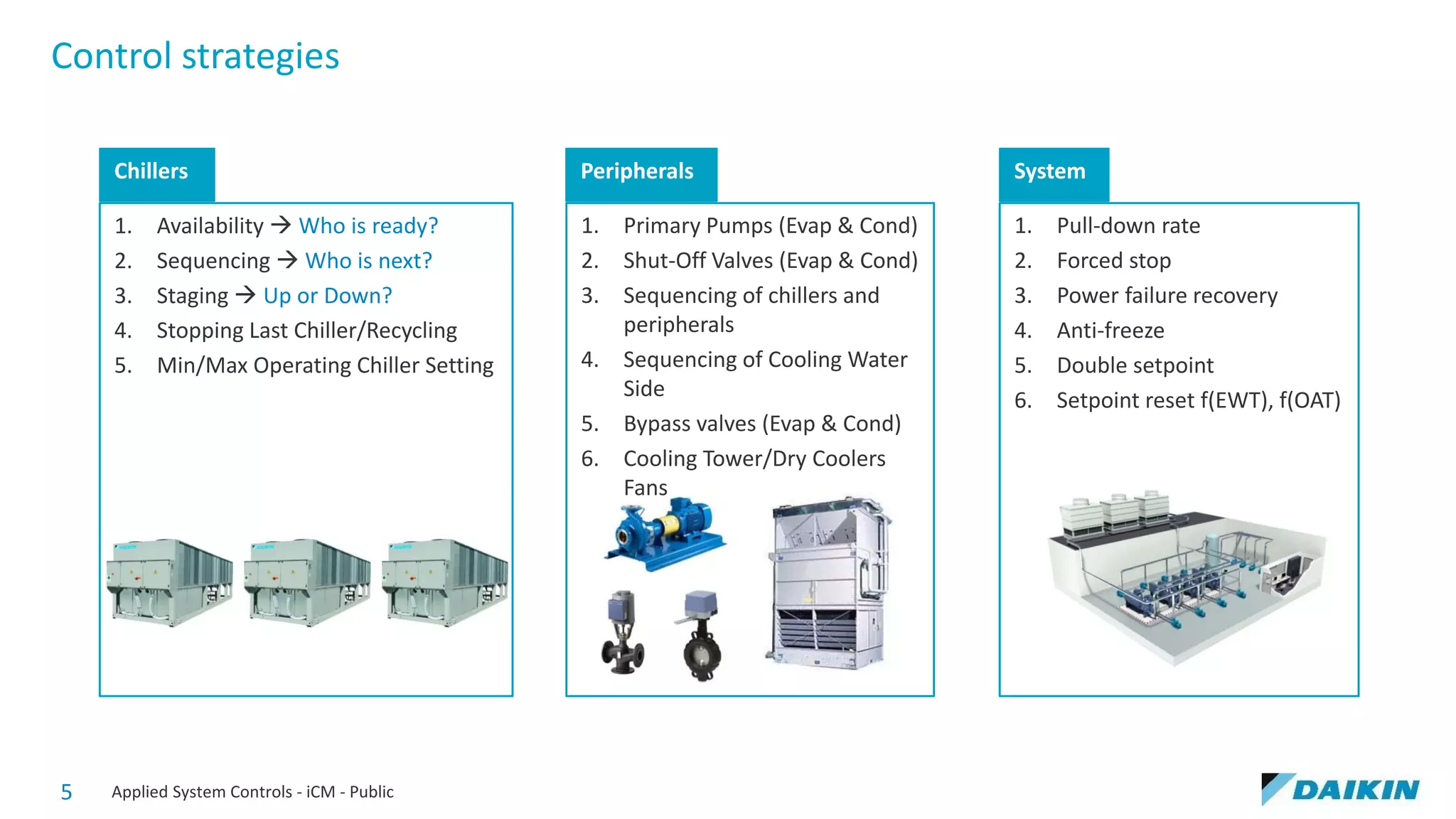

The document outlines the features and capabilities of the Intelligent Chiller Manager (ICM) from Daikin, designed to optimize the performance and reliability of chiller plant rooms. It highlights key benefits such as improved energy efficiency, easy installation, and the ability to control various components like pumps and chillers. Daikin offers customizable solutions to suit different customer needs, ensuring effective management of chiller operations.