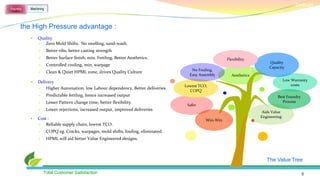

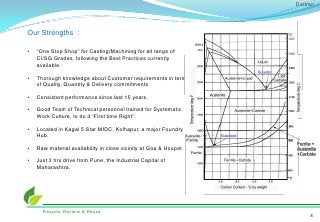

Deltran Diesels Engineering Pvt. Ltd. specializes in grey and SG iron casting and machining, with a production capacity of 1200 tonnes per month. The company employs advanced technologies and quality systems to ensure zero cost of poor quality, and focuses on best foundry practices, energy management, and employee satisfaction. Future plans include incorporating automation and creating a rapid prototyping center to support new models and compliance with emission norms.