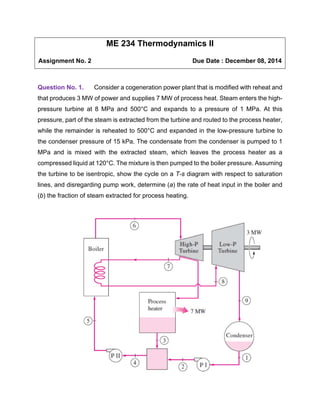

This document contains 4 questions regarding thermodynamics assignments on topics like cogeneration power plants, combined gas-steam power cycles, refrigeration cycles, and isentropic nozzle flow of carbon dioxide. Question 1 involves a cogeneration plant with reheat and asks to draw a T-s diagram and determine the heat input and steam extraction fraction. Question 2 involves a combined gas-steam cycle and asks to determine moisture content, steam temperatures, net power output, and efficiency. Question 3 involves a refrigeration cycle and asks to determine quality, refrigeration load, COP, and theoretical maximum load. Question 4 involves isentropic nozzle flow of CO2 and asks to calculate properties at different pressures and comment on how increasing inlet pressure