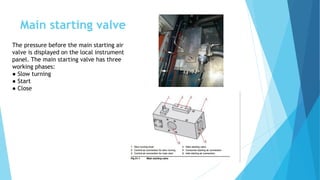

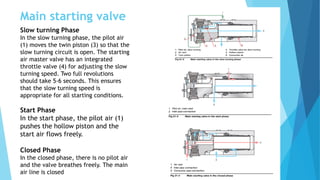

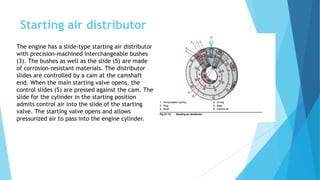

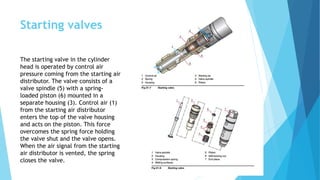

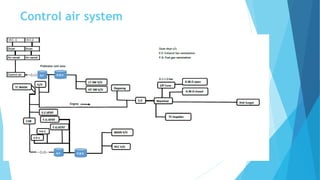

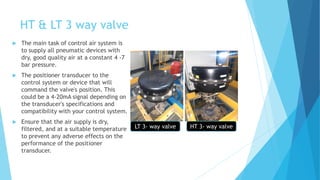

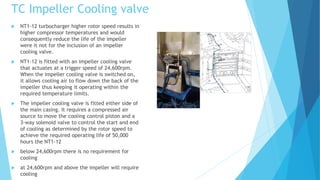

The document describes the components and functions of a compressed air system used for starting large engines. It includes specifications for the start air compressor, control air compressor, air vessels, and main components of the starting system. The main components are the main starting valve, starting air distributor, and starting valves, which control the flow of compressed air into the engine cylinders during starting. The control air system provides instrument air for pneumatic controls and valves throughout the system.