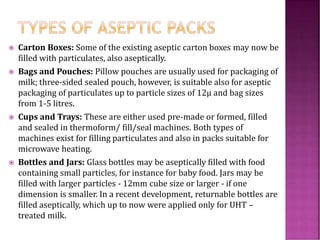

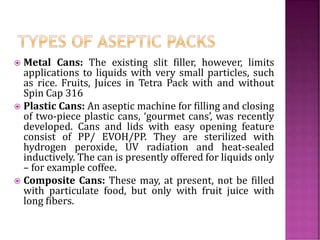

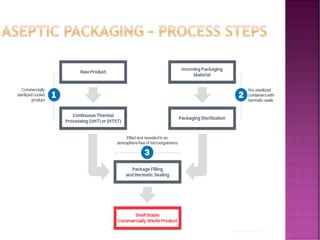

The document discusses aseptic processing, which is a technique for sterilizing liquid food or pharmaceutical products and packaging them in sterile containers to produce shelf-stable products without refrigeration. It describes various types of aseptic packaging materials like carton boxes, bags, pouches, cups, trays, bottles, jars, metal cans, plastic cans, and composite cans. It also outlines the key steps in aseptic processing like sterilization of products, packaging materials, and equipment to maintain sterility during filling and sealing. Benefits are listed as no refrigeration needed, protection of nutrients, and storage efficiency, while drawbacks include difficult recycling and higher production costs.