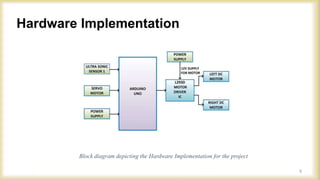

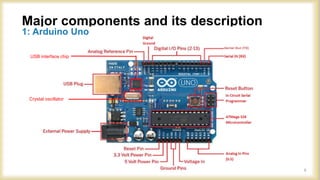

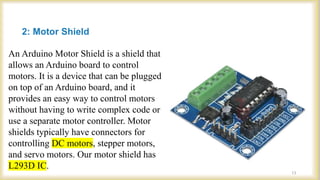

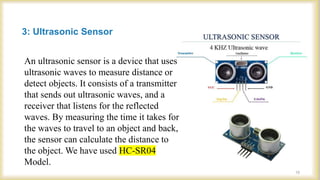

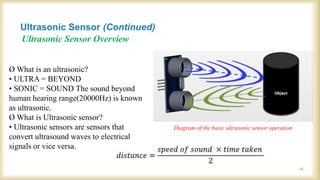

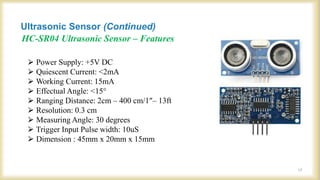

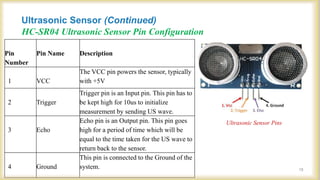

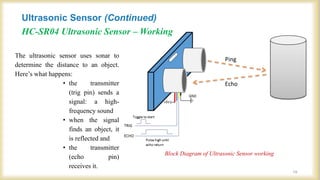

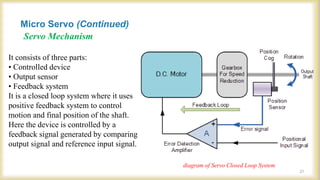

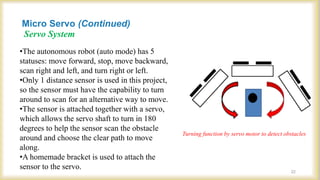

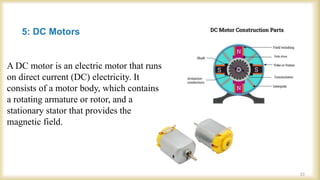

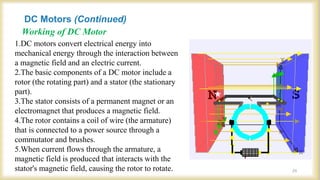

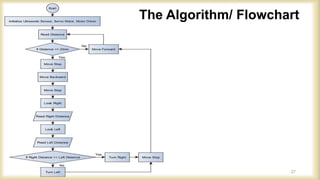

This document describes an Arduino-based obstacle avoiding robotic car. The car uses an ultrasonic sensor to detect obstacles and a micro servo to allow the sensor to scan the environment. It includes a motor shield and DC motors to control movement. The Arduino board processes sensor readings and sends signals to move around obstacles. Components are powered by a 9V battery. The goal is to autonomously navigate environments without human intervention.