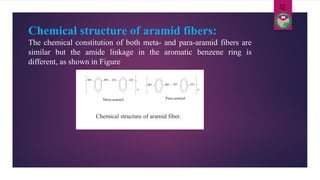

The document presents an overview of aramid fibers, detailing their properties, classifications, production methods, and applications. Aramid fibers are strong synthetic materials known for their heat, chemical, and abrasion resistance, making them suitable for protective clothing and other industrial uses. It also highlights the distinctions between meta-aramids and para-aramids, including their specific applications and advantages.

![ END USE OF ARAMID FIBER:

▪ Flame-resistant clothing

▪ Heat protective clothing and helmets

▪ Body armor [competing with PE based fiber products

such as Dyneema and Spectra]

▪ Composite materials

▪ Asbestos replacement (e.g. braking pads)

▪ Hot air filtration fabrics

▪ Tires, newly as Sulfone (sulfur modified Twaron)

▪ Mechanical rubber goods reinforcement

▪ Ropes and cables

▪ Wicks for fire dancing

▪ Optical fiber cable systems

18](https://image.slidesharecdn.com/presentationonaramidfibre-duet-201220081214/85/Presentation-on-aramid-fiber-DUET-17-320.jpg)