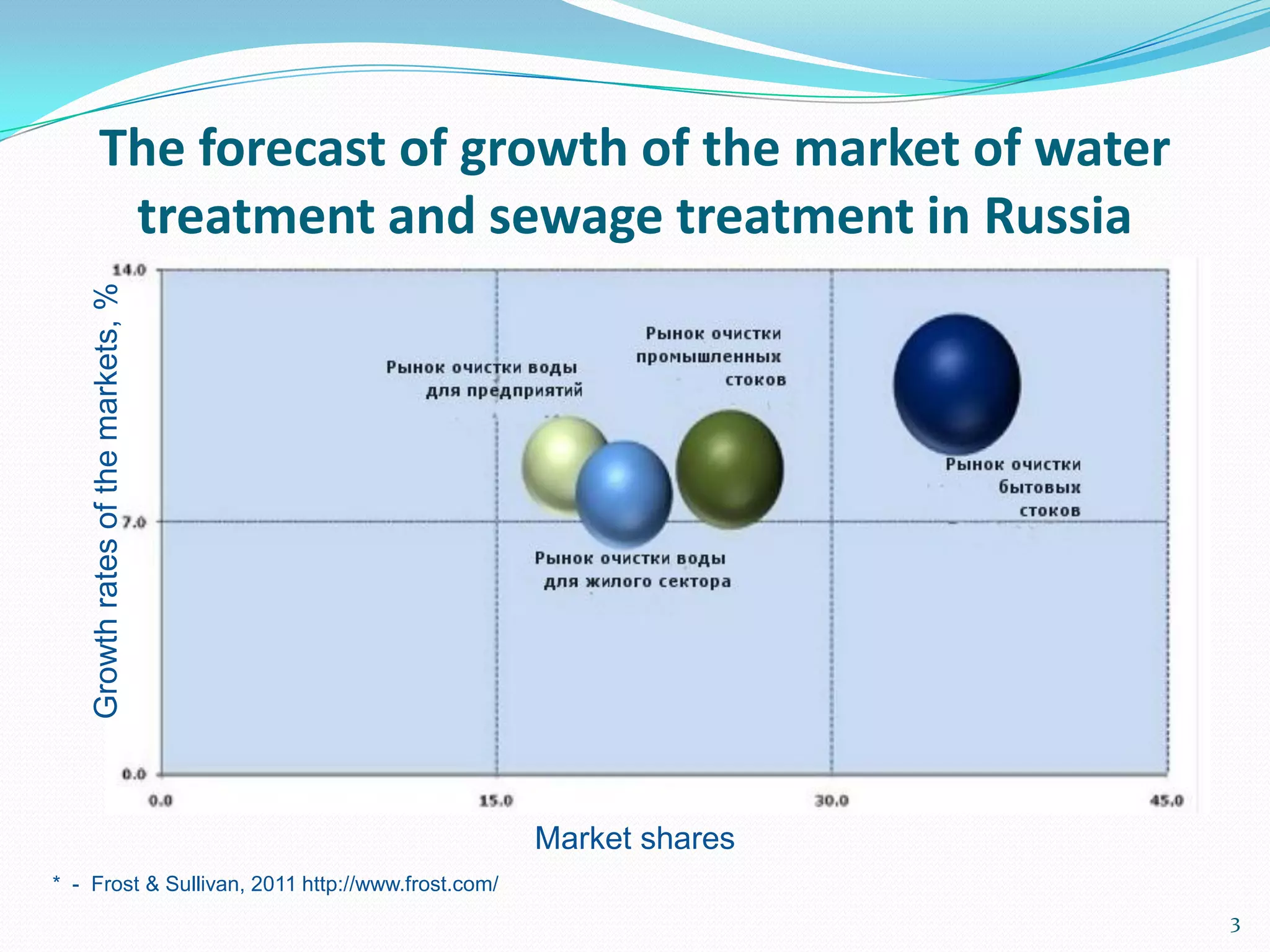

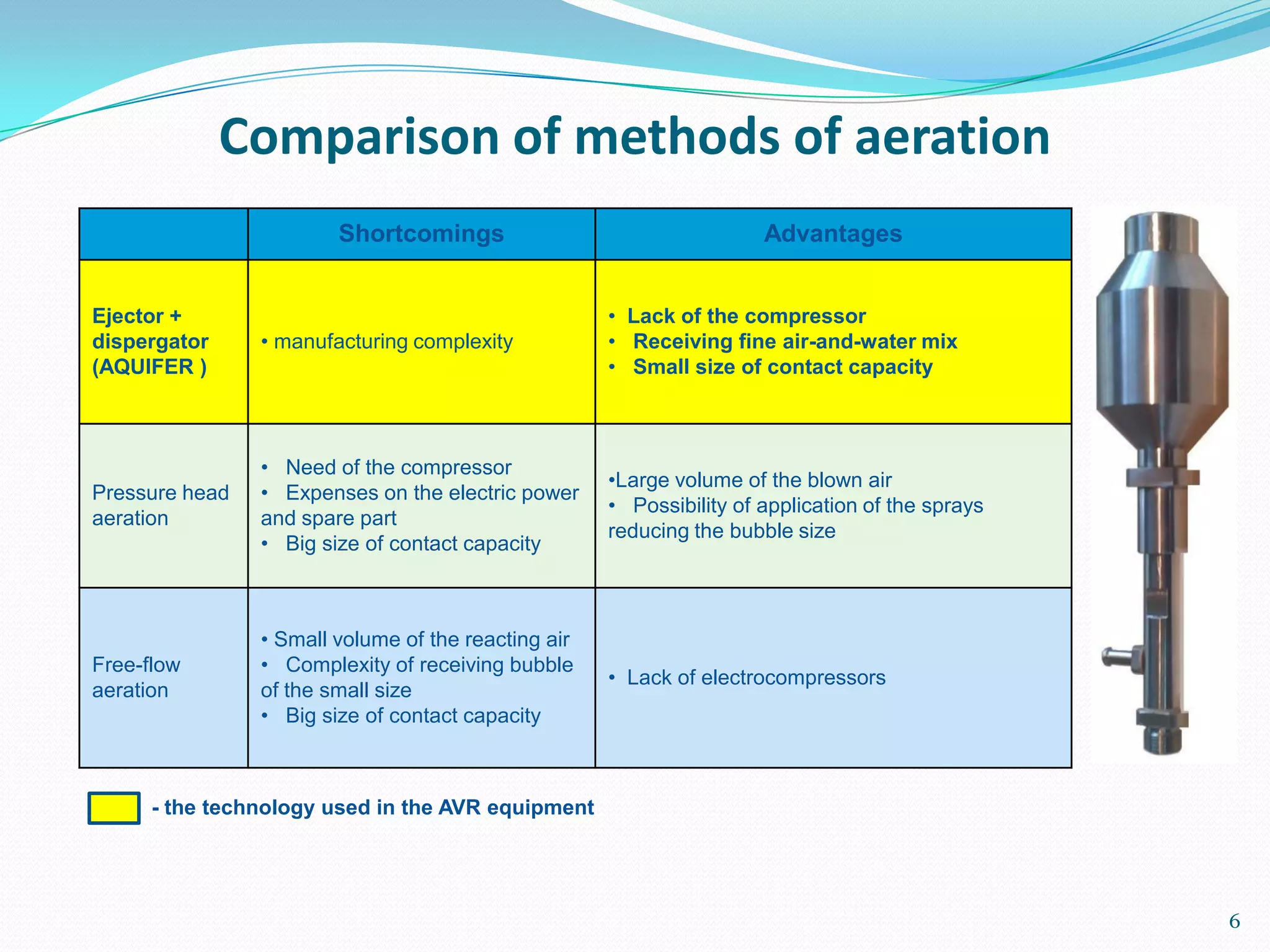

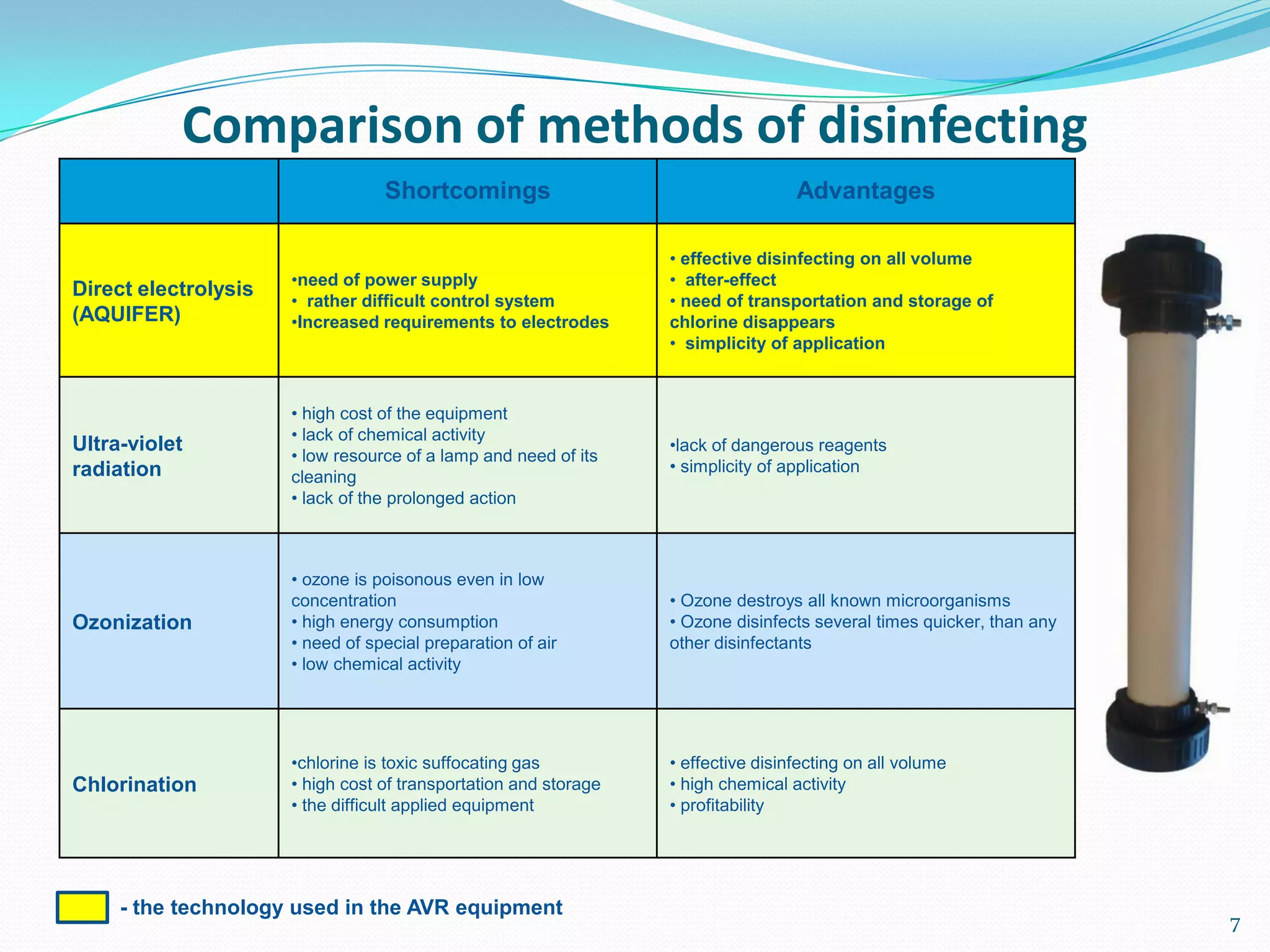

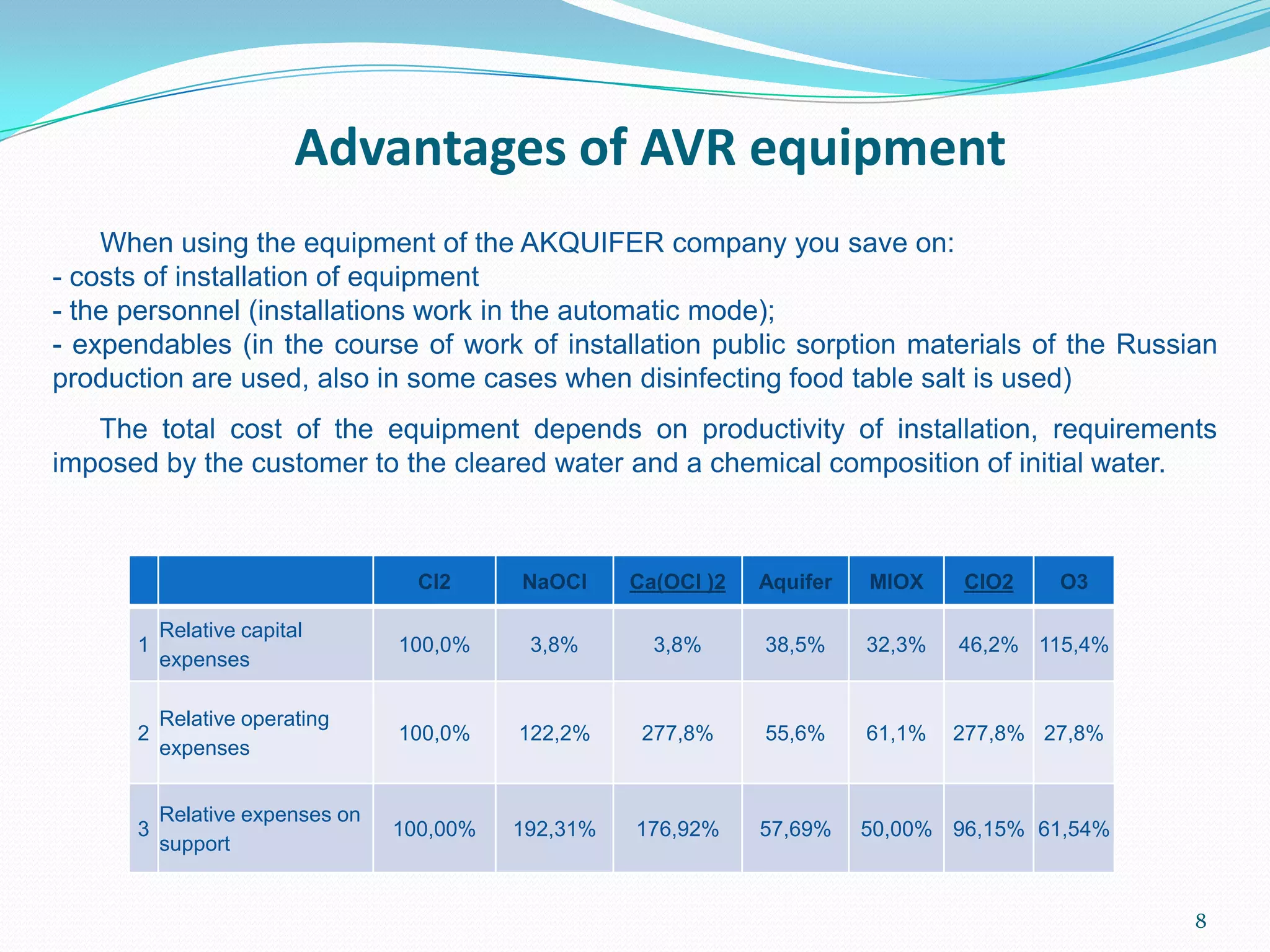

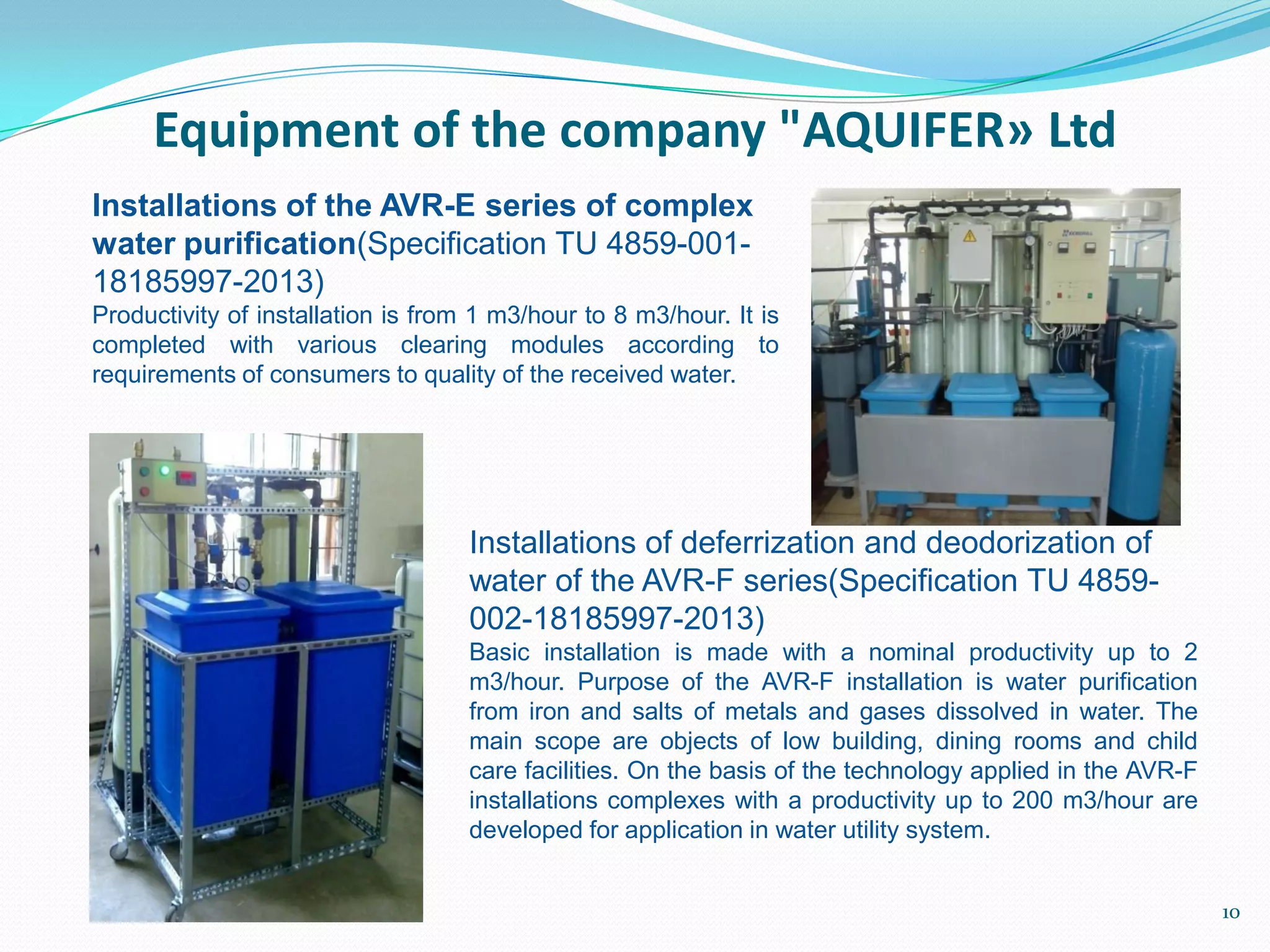

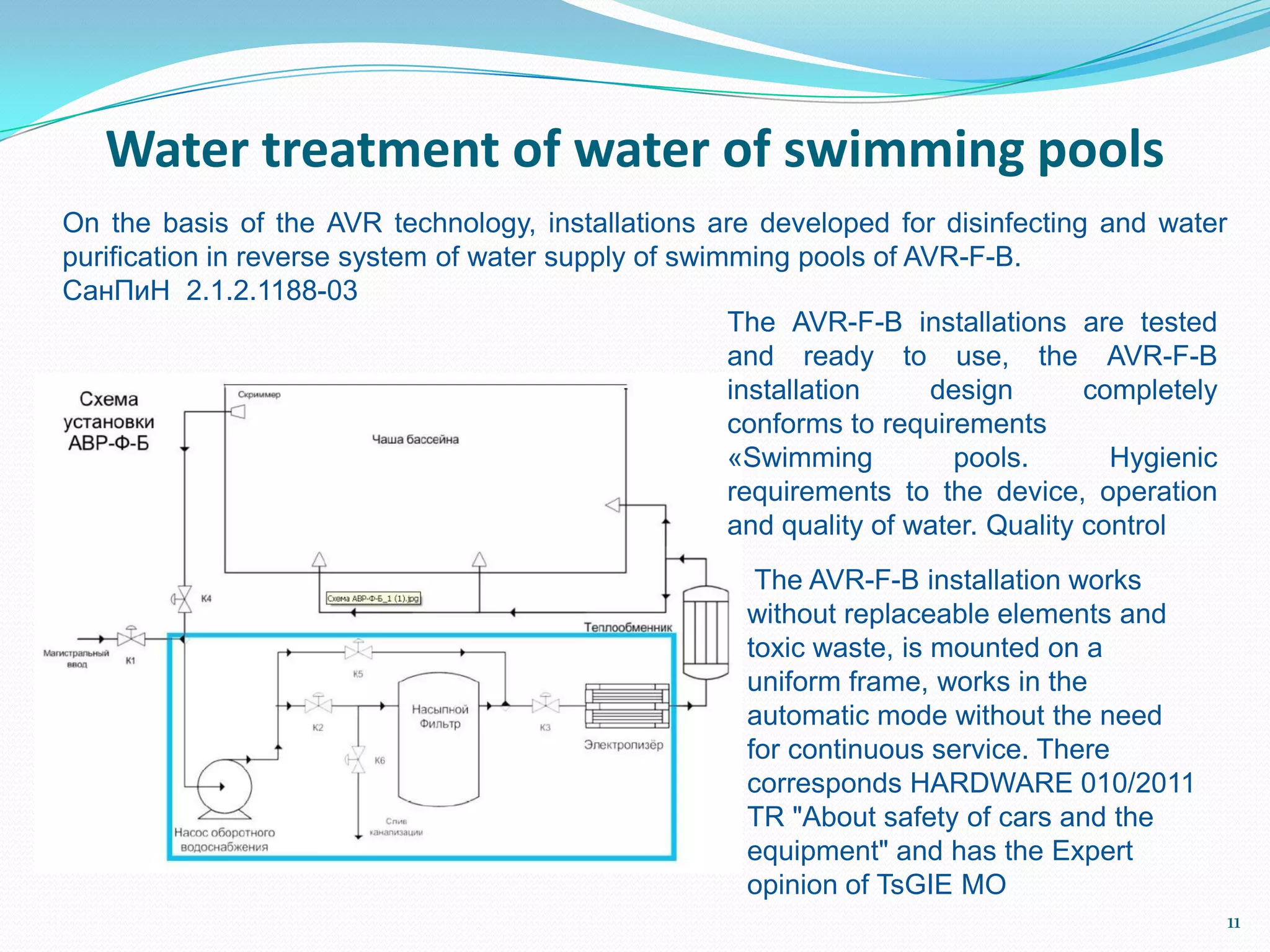

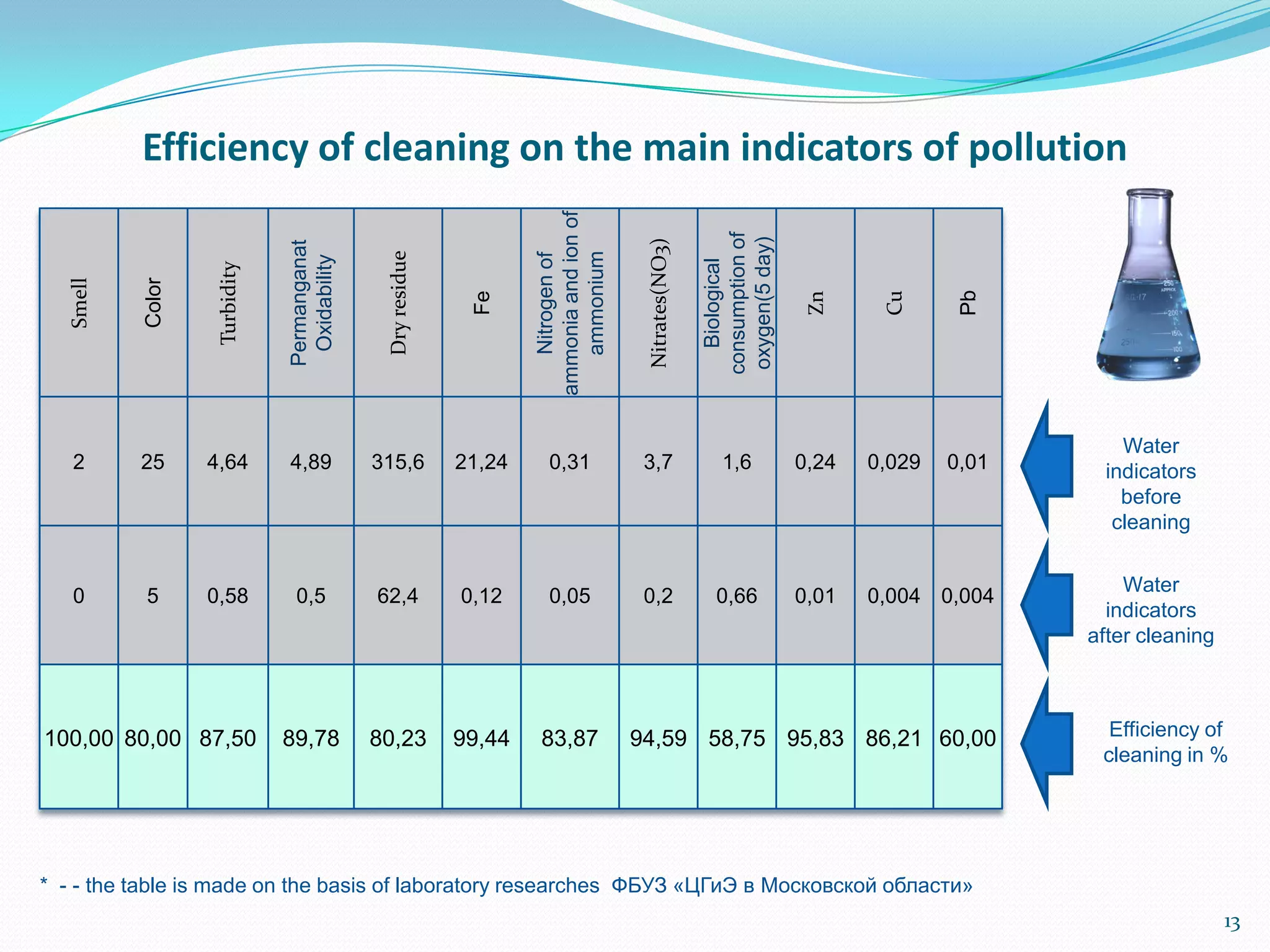

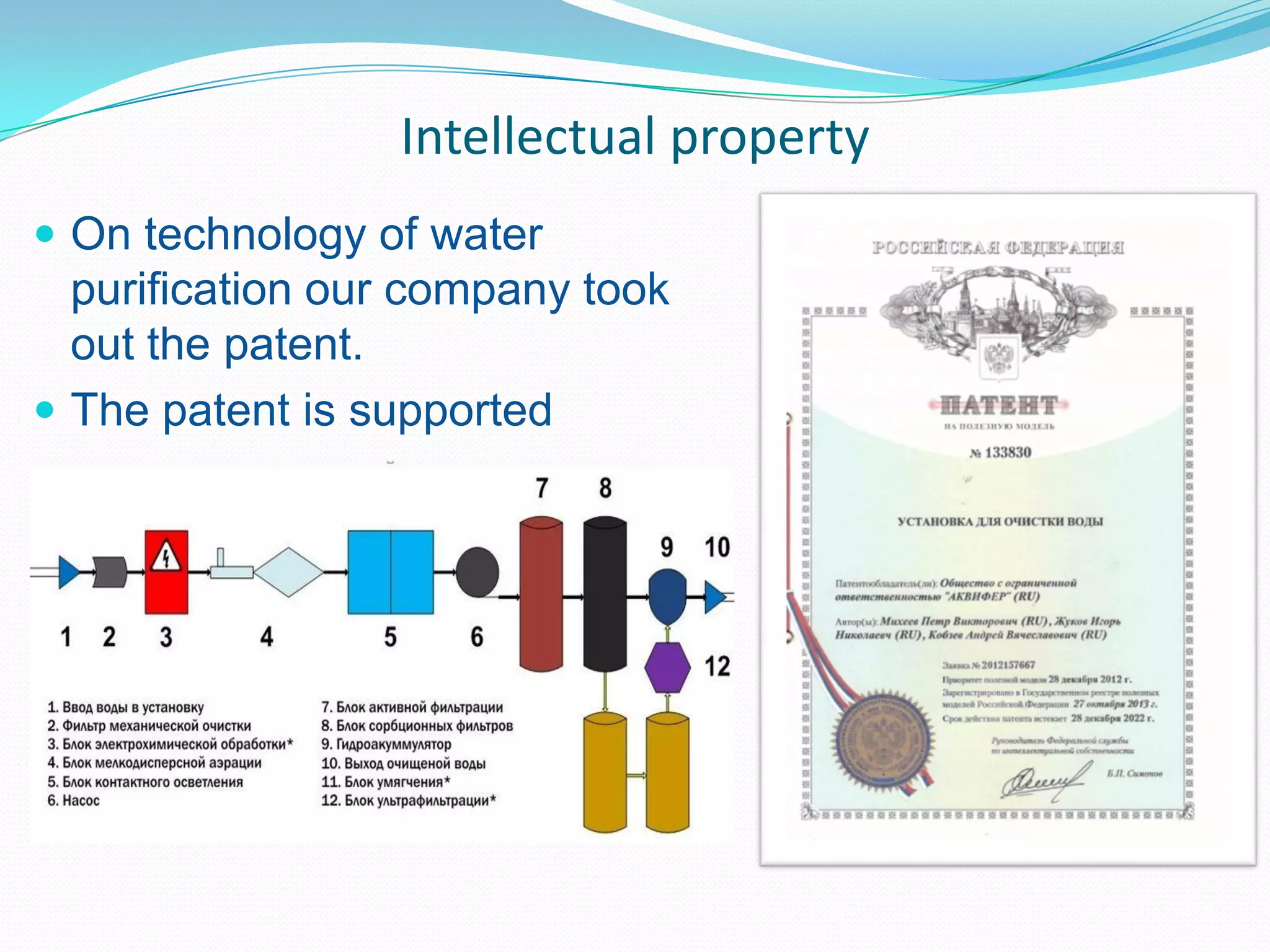

The document discusses the challenges of water purification, particularly the need for cost-effective solutions that avoid the use of chlorine and expensive reagents. It details the advantages of the AVR installations developed by Aquifer, which utilize advanced technologies for efficient water treatment without the need for toxic chemicals, thus reducing overall operational costs. Additionally, the text highlights the market potential for Aquifer's products in various sectors, including municipal and industrial applications.