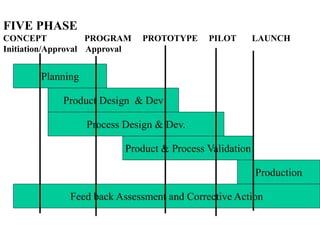

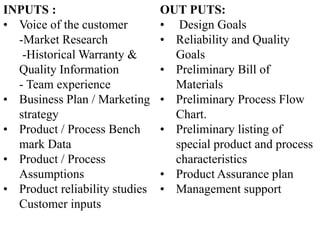

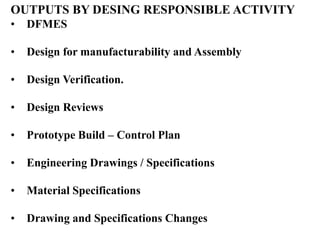

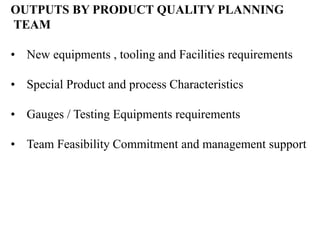

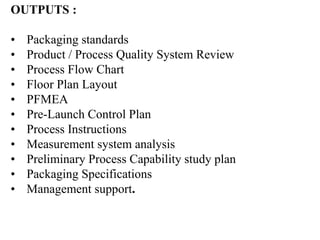

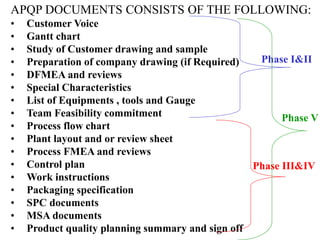

The document discusses ISO 9000 quality standards and the Advanced Product Quality Planning (APQP) process. It provides an overview of the ISO 9000 series including ISO 9001, 9002, 9003, 9004, and QS-9000. It then describes the five phases of APQP: planning, product design, process design, validation, and feedback/improvement. Each phase lists typical inputs, outputs, and goals to ensure products satisfy customer requirements through effective planning and continuous improvement.