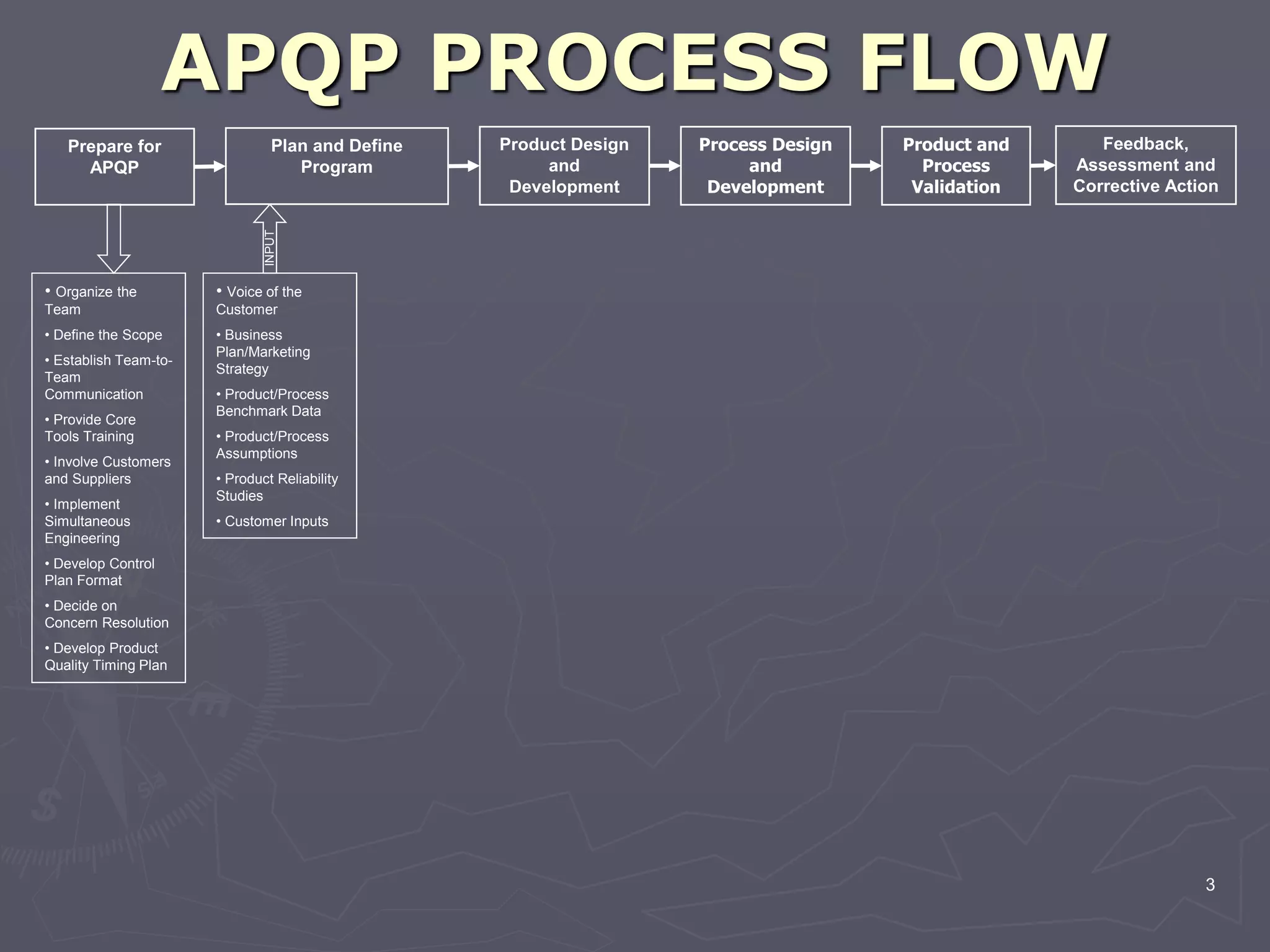

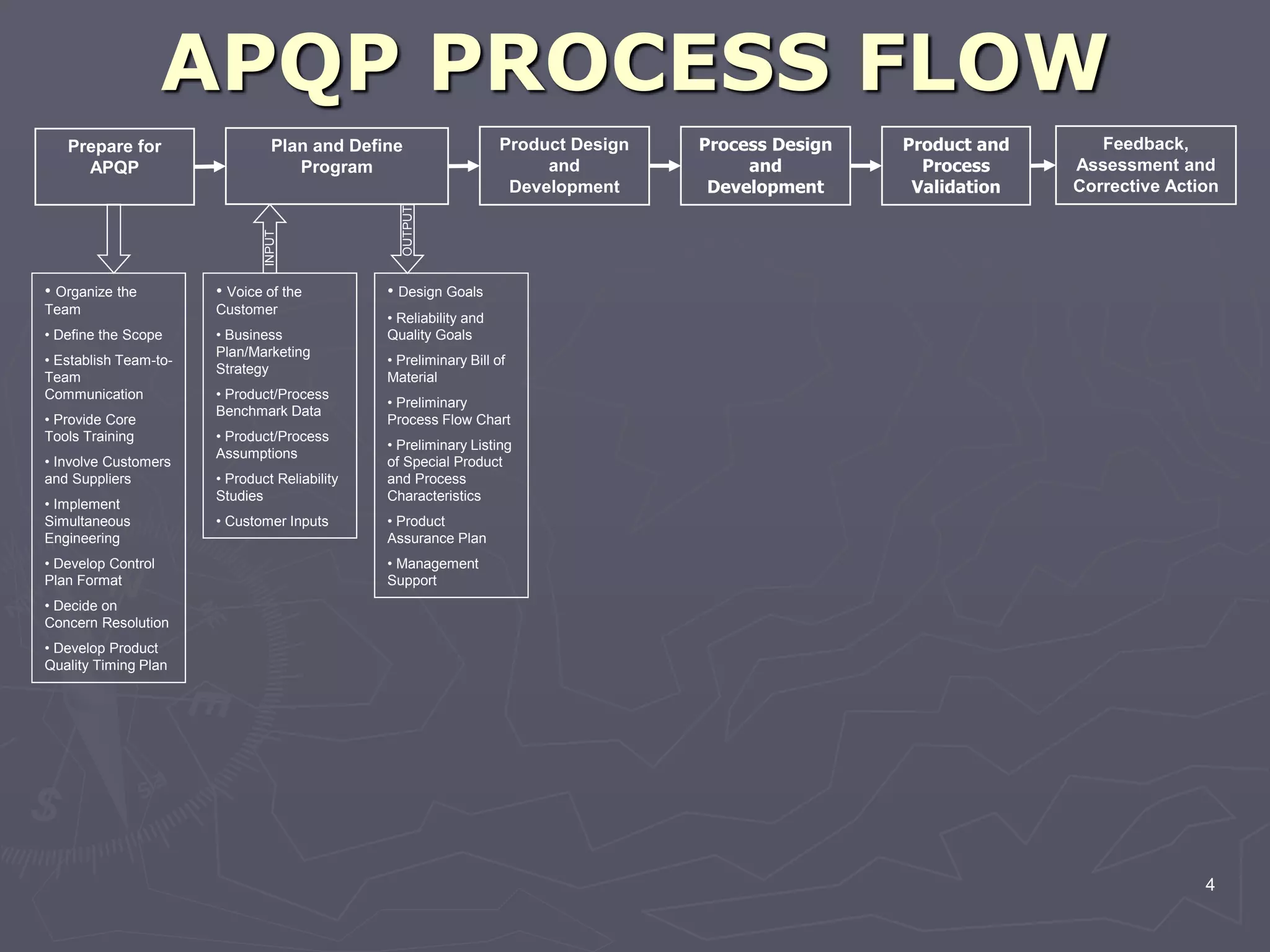

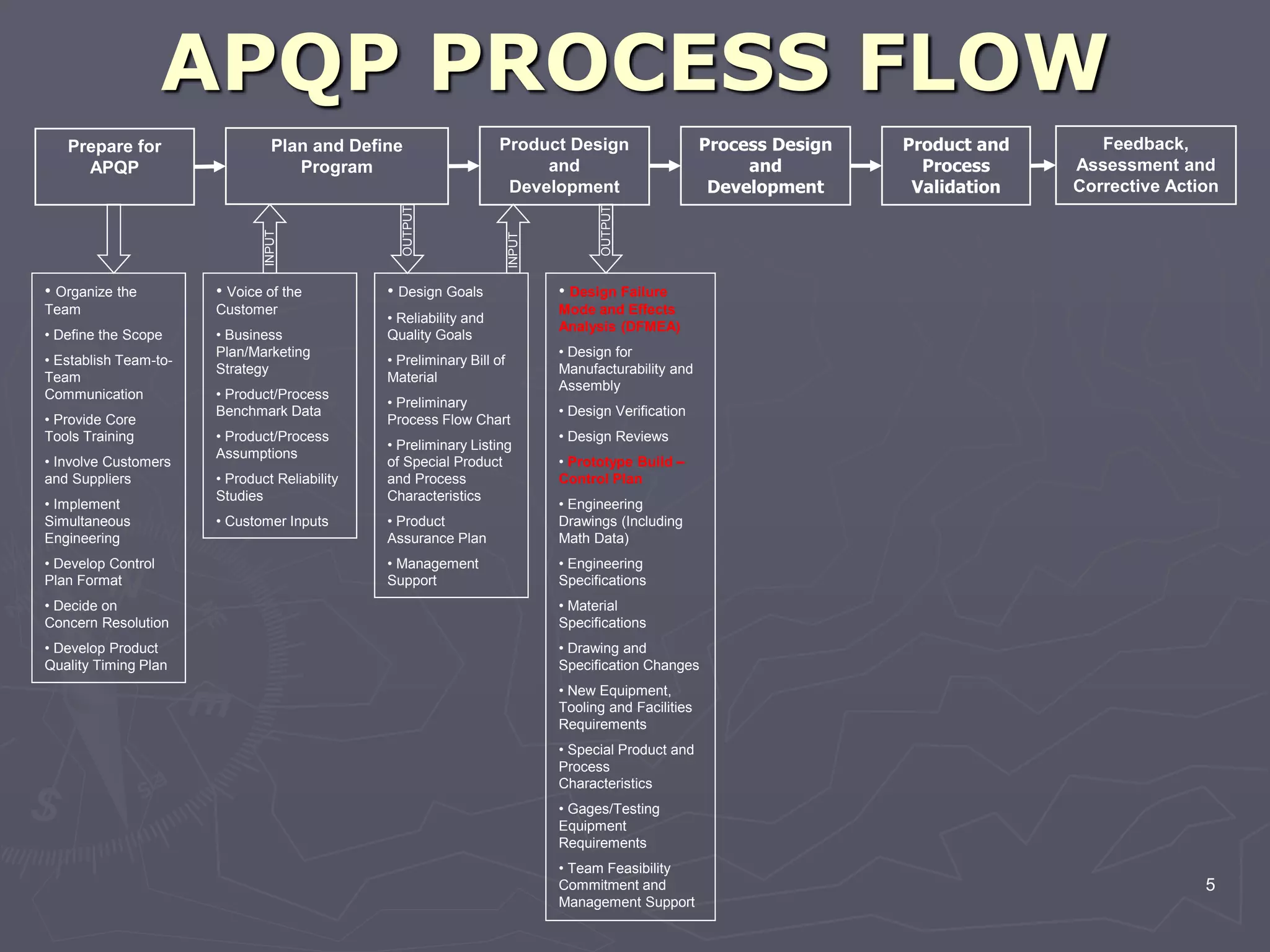

The document outlines the Advanced Product Quality Planning (APQP) process, which consists of several phases: Prepare for APQP, Plan and Define Program, Product Design and Development, Process Design and Development, Product and Process Validation, and Feedback, Assessment and Corrective Action. It provides inputs and outputs for each phase to ensure new products and processes meet quality objectives and customer requirements. The goal of APQP is to reduce variation and improve customer satisfaction through cross-functional teamwork and planning across the entire product development lifecycle.