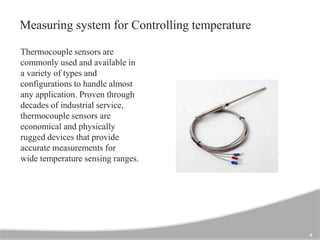

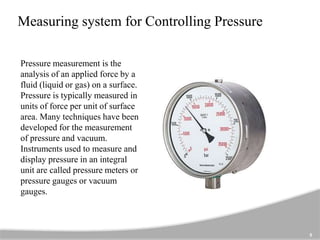

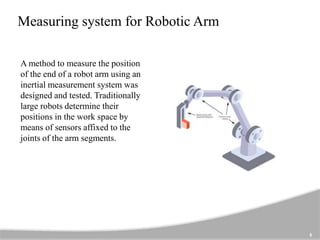

The document discusses various applications of measurement systems in instrumentation and control, including devices for monitoring temperature, pressure, shaft speed, fluid flow, and robotic arm positioning. It highlights the significance of feedback systems in controlling various parameters across diverse industries. Specific measuring devices like thermocouples, pressure gauges, tachometers, and the pitot-static tube system are described for their roles in accurate measurements.