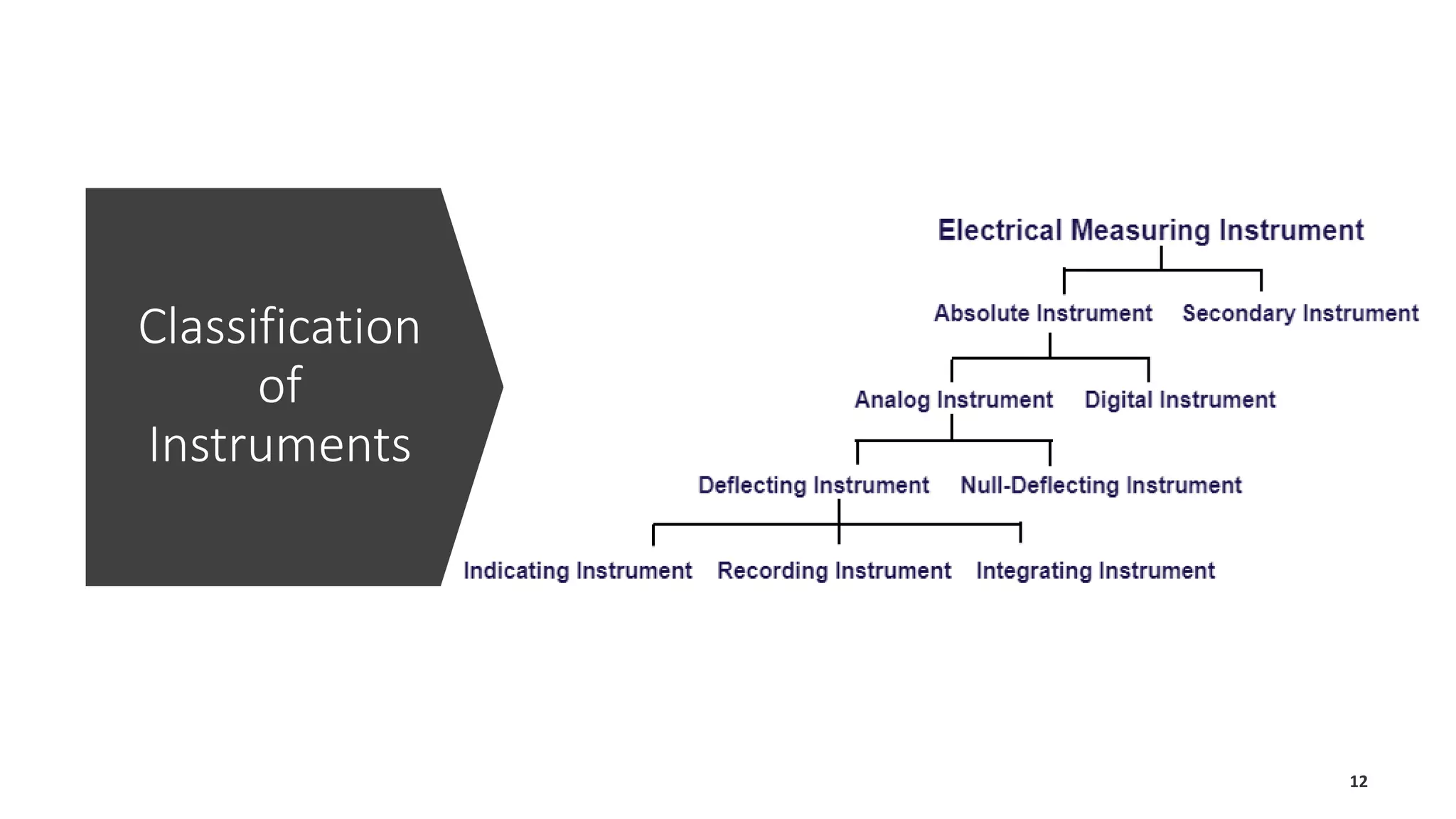

This document provides an overview of measurements and measurement systems for a first year electrical engineering course. It discusses key concepts such as the definition of measurements, importance of measurements, types of measurements including direct and indirect, and real-world applications of electrical and electronic measurements. The document also covers instruments and measurement systems, types of instruments including mechanical, electrical, electronic, classifications of instruments such as absolute vs secondary and deflection vs null types. It concludes with discussing the analog and digital modes of operation and functions of instruments including indicating, recording, and integrating instruments.