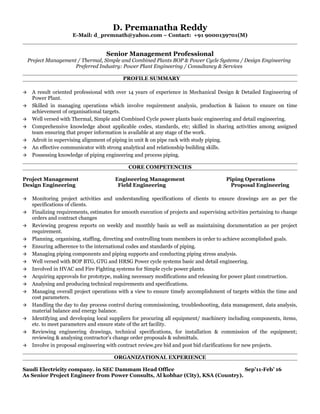

This document provides a summary of D. Premanatha Reddy's professional experience and qualifications. He has over 14 years of experience in mechanical design and engineering for power plants. Some of his roles and responsibilities have included basic and detailed engineering for BOP and power cycle systems, reviewing contractor drawings and documents, project monitoring, and proposal engineering. He has worked on various power plant projects in India and Saudi Arabia for companies like Saudi Electricity Company, Citec Engineering, and Nagarjuna Construction Company.