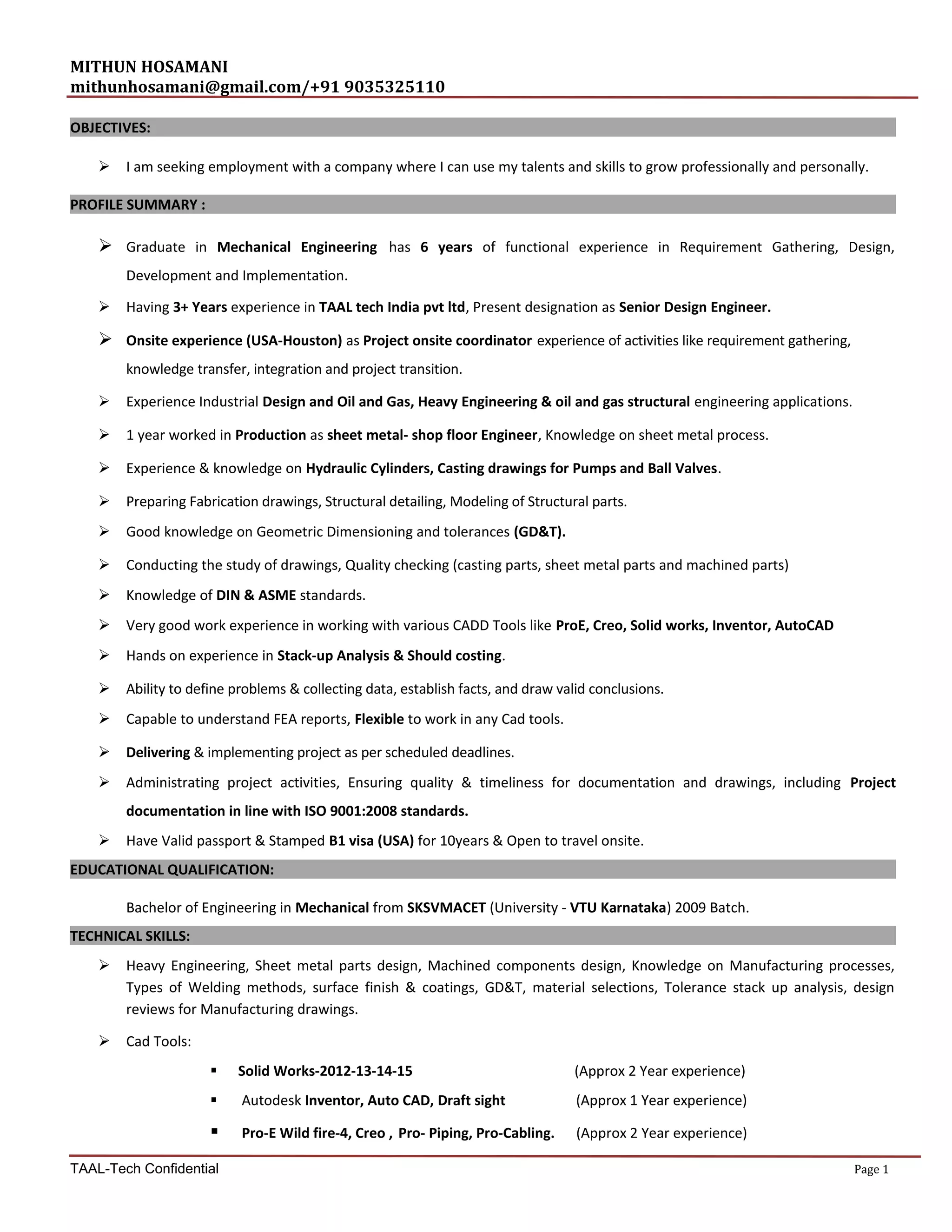

Mithun Hosamani is seeking a role where he can use his 6 years of experience in mechanical engineering. He has worked as a senior design engineer developing products for oil/gas industries. His skills include CAD tools like SolidWorks and Creo, designing mechanical parts, preparing drawings, and ensuring projects meet deadlines and quality standards. He has onsite experience in the US and is open to additional travel.