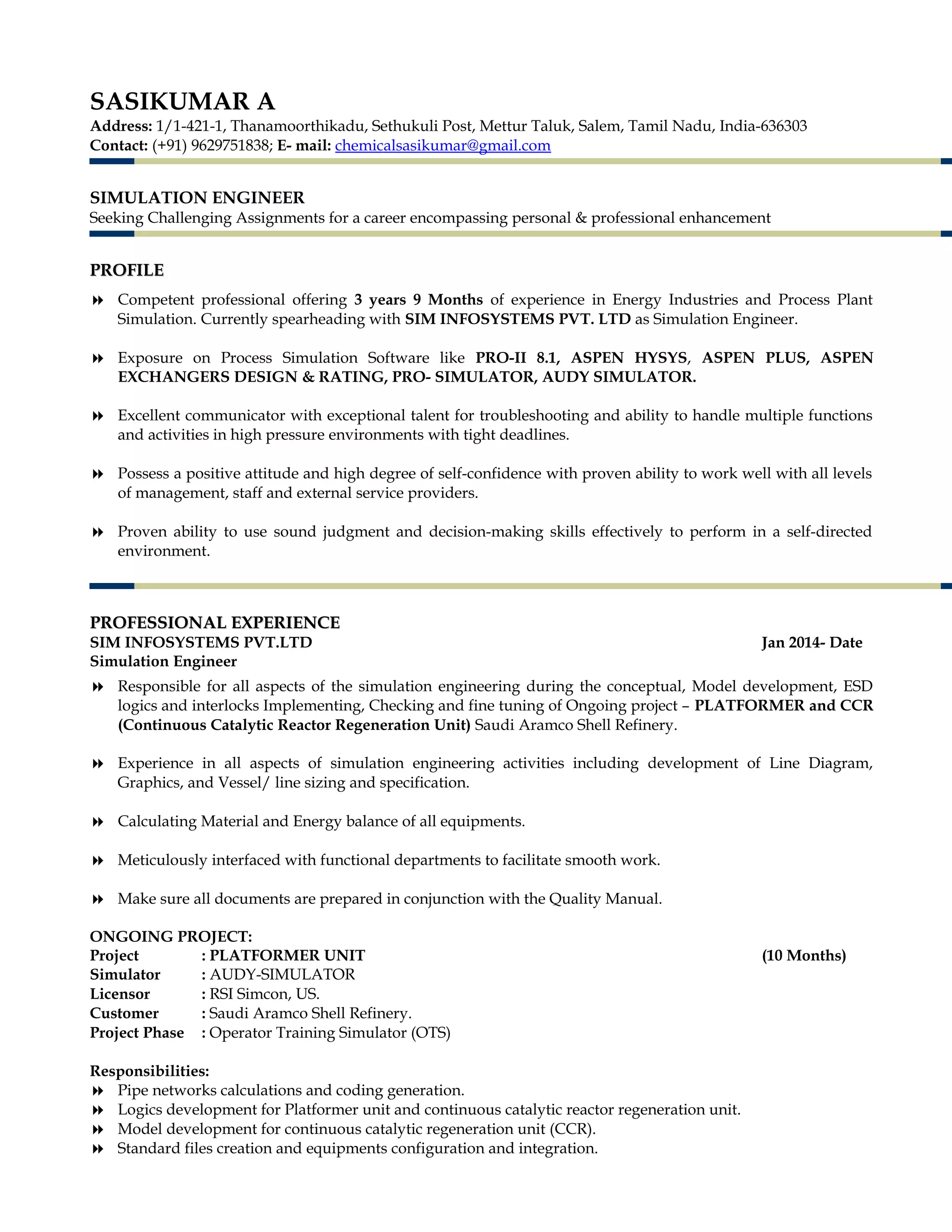

Sasikumar is a simulation engineer with over 3 years of experience using software like PRO-II, ASPEN HYSYS, ASPEN PLUS. He is currently working as a simulation engineer for SIM INFOSYSTEMS PVT. LTD on projects for Saudi Aramco Shell Refinery. He has experience developing models, logics, and simulations for units like platformers, CCR units, steam systems, and hydro-treating units. Previously he worked as a commissioning engineer and ASPEN HYSYS faculty. He holds a BTech in chemical engineering.