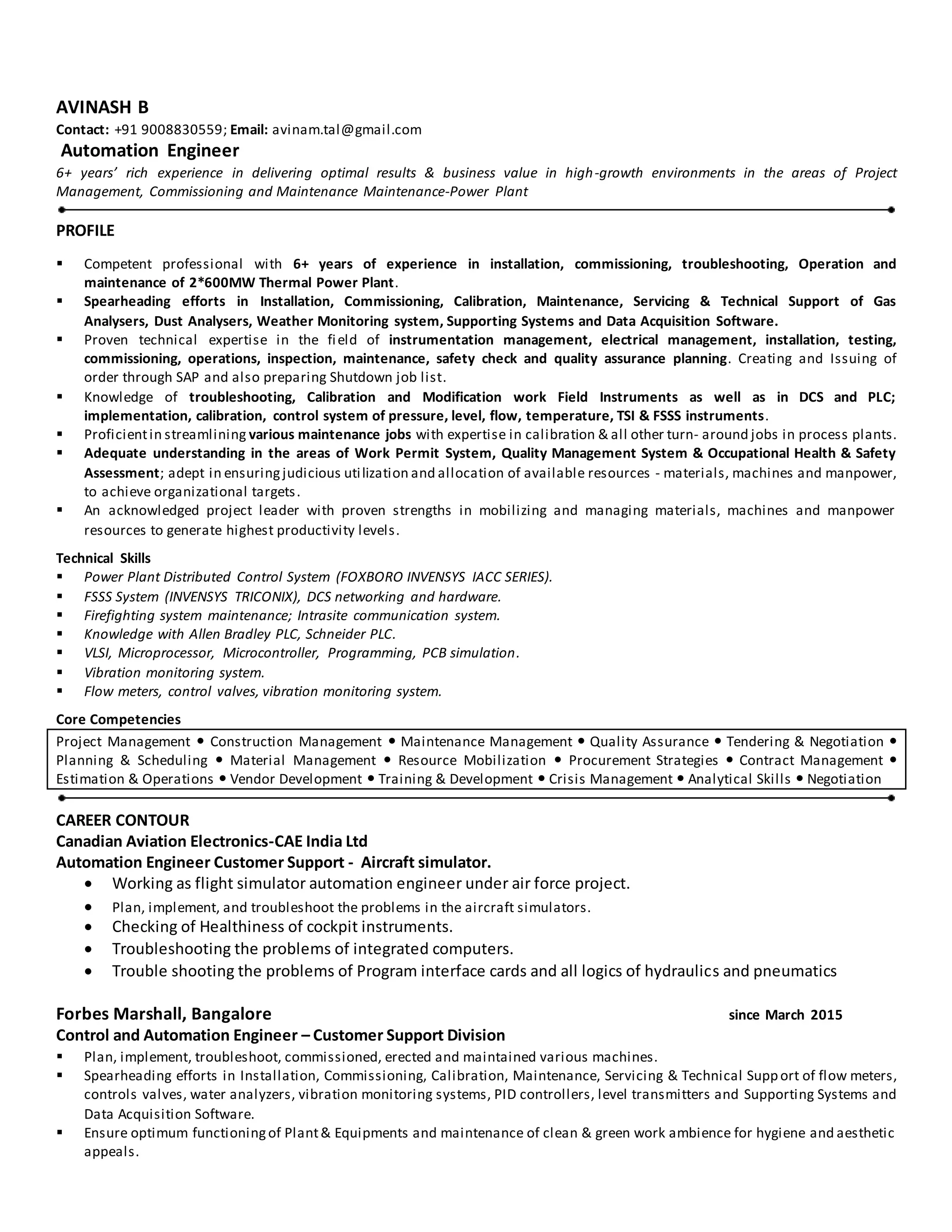

This document contains the resume of Avinash B, an automation engineer with over 6 years of experience in power plant maintenance, commissioning, and operations. He has spearheaded installation, calibration, and maintenance of various instrumentation systems like gas analyzers, weather monitoring systems, and DCS. He is proficient in PLCs, process instrumentation, and has experience working with control systems from manufacturers like Foxboro, Allen Bradley, and Schneider. His career includes roles supporting aircraft simulators, process plants, and serving as a senior engineer at a gas analyzer company. He holds a diploma in electronics and has attended various technical trainings.