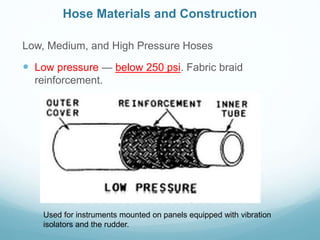

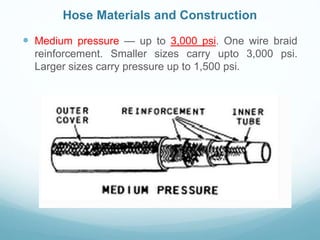

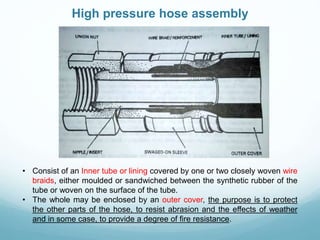

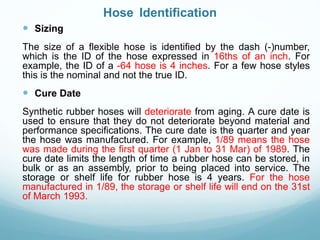

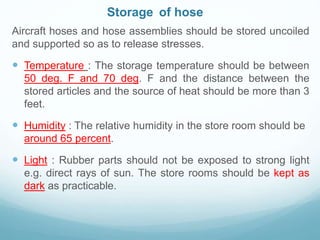

The document discusses aircraft hoses. It defines hoses and their uses in aircraft fluid systems. Hoses are classified into two groups: Group A for fuel, oil, pneumatic and hydraulic pressure hoses and Group B for other hoses like hydraulic return lines. The document discusses hose materials, construction, identification, storage, installation, and service lives. Hoses have shelf lives of 10 years and service lives of 4-6 years for Group A hoses and 6-8 years for Group B hoses.