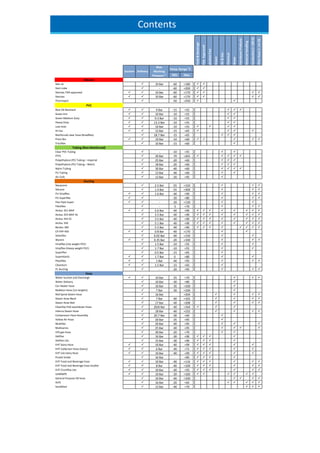

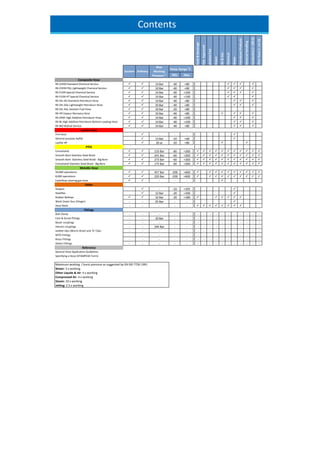

The document is a product guide from ERIKS Hose Technology (EHT) that provides information on their selection of hoses, ducting, fittings and other products. It includes details on various hose types made from materials like silicone, PVC, PTFE, composite and metallic hoses. Product specifications are provided in a table that lists information like temperature range, pressure ratings and applications for different industries. The guide aims to help customers select the right hose or ducting for their needs and also provides contact details for EHT.

![Tricoflex

Water hose

692-693 Stirling Road No.12 Osyth Close

Slough Brackmills Industrial Estate

Berkshire Northampton

SL1 4ST NN4 7DY

Tel: +44 (0)1753 570863 Tel: +44 (0)1604 877668

Email: eht-sales@eriks.co.uk Web: http://www.eriks-hose-technology.com

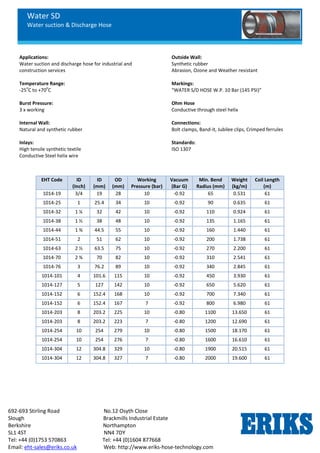

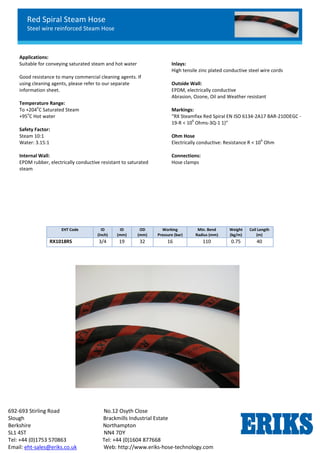

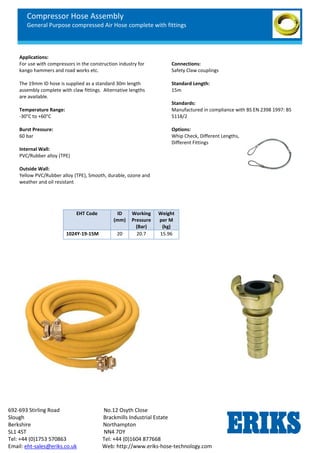

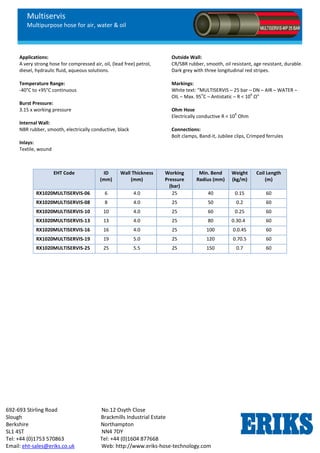

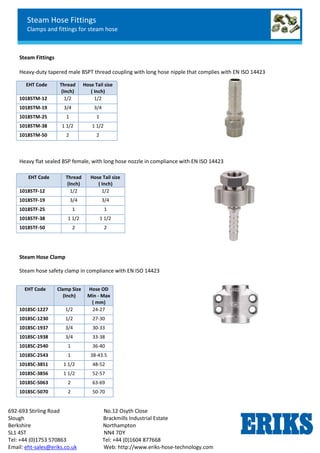

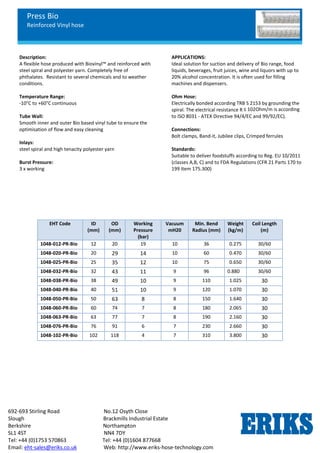

Applications:

The multilayer design, made of an exclusive woven fibre and

a double core layer, ensures that Tricoflex is highly flexible

for easy handling, with excellent resistance to repeated

bending, crushing and pulling as well as minor deformation

under pressure.

In addition, the lining is extremely smooth, thereby

maintaining even flow. Especially thick and made of high

quality materials, Tricoflex offers remarkable ageing

resistance with exceptional preservation of flexibility. Its

exterior yellow PVC covering gives it good protection against

abrasion and UV rays.

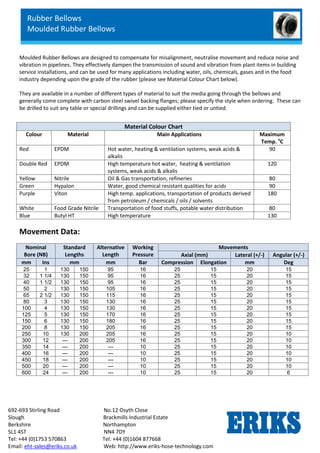

Temperature Range:

-15

o

C to +60

o

C

Internal Wall:

Smooth black two-layer inner tube

Inlays:

Wound textile inlays

Outside Wall:

Yellow PVC coating

Markings:

TRICOFLEX Soft & Flex Technology [batch number]

Connections:

RX ® hose clamps, Band-it, Jubilee clips, Bolt Clamps.

Connectors with band, screw or ‘O’ type clamps. Automatic

connectors for watering.

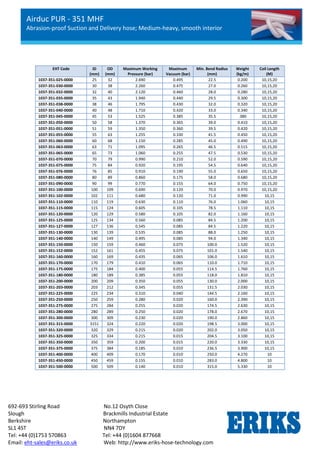

EHT Code ID

(mm)

Wall Thickness

(mm)

Working Pressure

Water (bar)

Burst Pressure

water (bar)

Min. Bend

Radius

Coil Length

1003T-12-25M 12.5 2.75 10 25 125 25, 50 & 100

1003T-15-25M 15 2.75 10 25 135 25, 50 & 100

1003T-19-25M 19 3.25 9.2 23 180 25, 50 & 100

1003T-25-25M 25 3.75 8 20 240 25, 50 & 100

1003T-30-25M 30 4.5 8 20 300 25, 50 & 100

1003T-35-25M 35 5 8 20 350 25, 50 & 100

1003T-40-25M 40 5.5 8 20 400 25, 50 & 100

1003T-50-50M 50 6.5 8 20 500 25, 50 & 100](https://image.slidesharecdn.com/dab7f1e6-78ce-44c3-b180-3cee56e5549c-160425211307/85/Product-Guide-18-320.jpg)