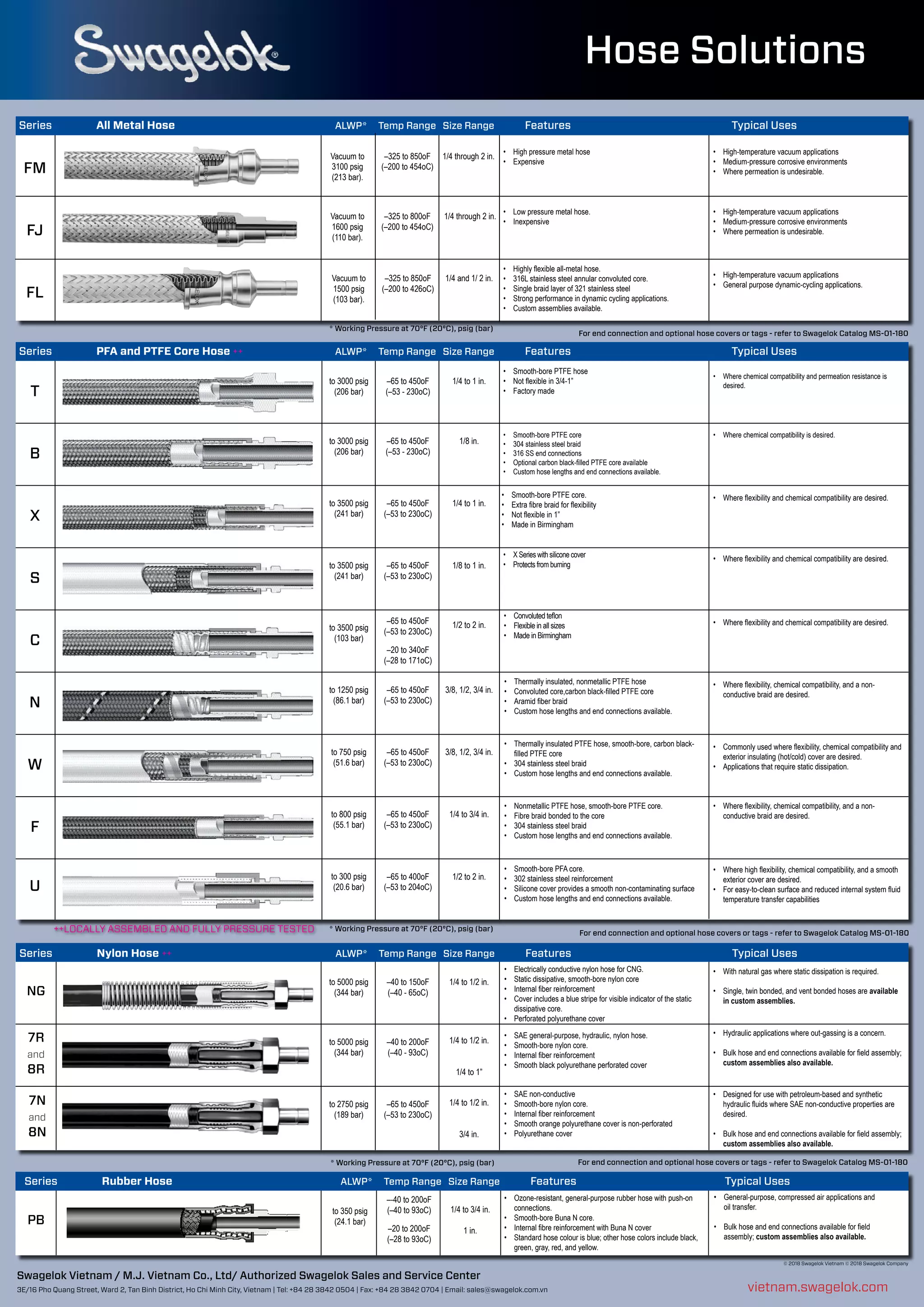

This document summarizes various hose solutions from a company including the type of hose material, temperature and pressure ranges, sizes, features, and typical uses. It includes metal hoses with stainless steel cores for high pressures and temperatures. It also includes PTFE and nylon hoses for flexibility and chemical compatibility in various industries. Rubber hoses are listed for general purpose air and fluid transfer applications. Contact information is provided for the Vietnam authorized distributor of these hoses.