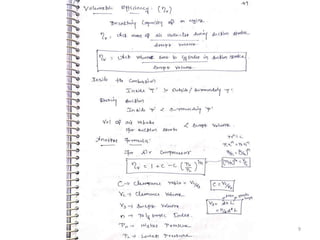

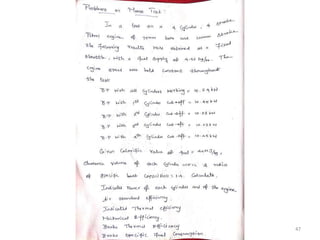

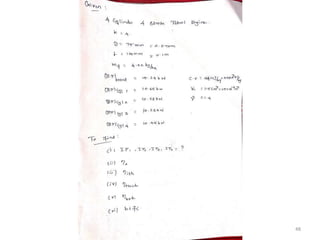

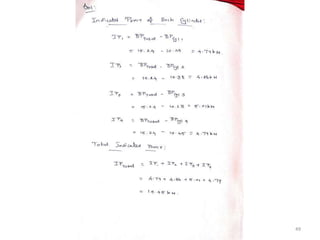

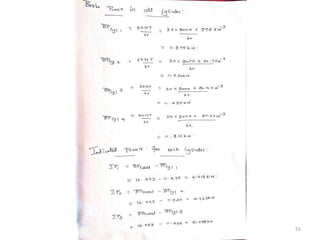

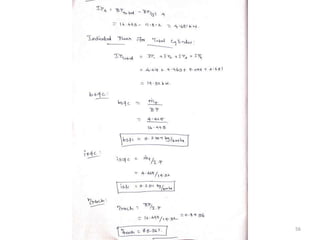

The document discusses various terminology used in internal combustion engines. It defines terms like cylinder bore, piston area, stroke, dead center, displacement volume, clearance volume, and compression ratio. It describes that cylinder bore is the inner diameter of the working cylinder, piston area is the area of the circle with diameter equal to the cylinder bore, and stroke is the distance the piston moves between reversals. It also defines top dead center and bottom dead center as the positions of the piston at the extremes of the stroke.