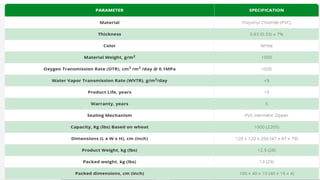

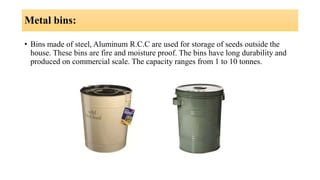

The document discusses various advances in seed storage methods. It notes that proper storage is important to maintain seed quality until planting. Methods discussed include drying seeds to safe moisture levels, using structurally sound storage structures in cool areas, hermetic bags, metal bins, treated jute and paper bags, and modern fumigation techniques using gases like methyl bromide to kill insects in stored seeds and grains. Good storage practices involve cleaning, pest control, and regular inspection and treatment if needed.