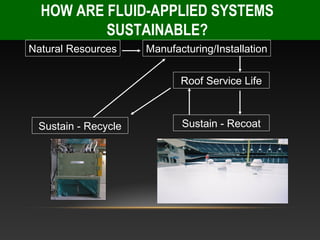

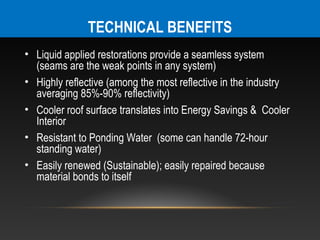

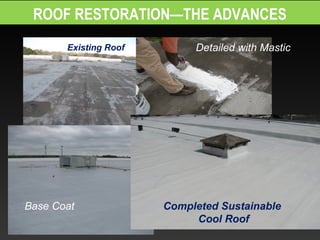

Washington Roofing & Insulation provides polyurethane spray foam and fluid-applied roof coatings with over 30 years of experience. They serve several Midwestern states from multiple office locations. Fluid-applied roof coatings offer a proven, high-performance, and sustainable alternative to traditional re-roofing through ease of installation, maintenance, and the ability to be renewed through re-coating. Building owners choose restoration over re-roofing for technical, economic, and environmental benefits like minimal disruption and ease of long-term maintenance.