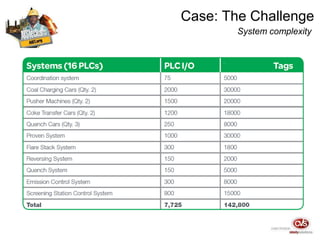

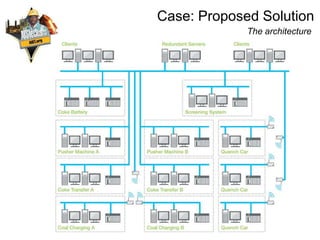

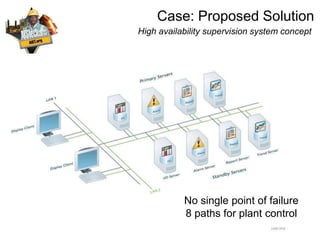

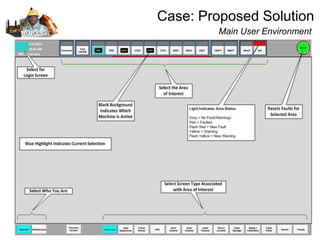

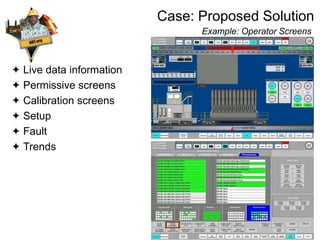

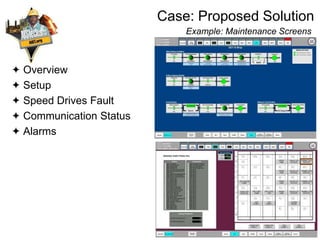

The document outlines a new advanced supervisory control system for coke plants, designed to improve automation and coordination among various processes while ensuring operational continuity even during subsystem failures. Key features include a scalable architecture with redundant systems, real-time monitoring capabilities, and a user-friendly graphical interface for operators and maintenance personnel. The solution aims to enhance efficiency and safety, significantly reducing downtime and development time for large production environments.