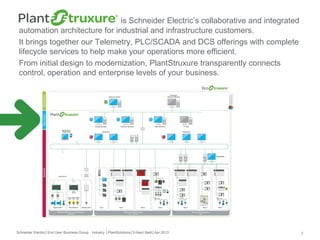

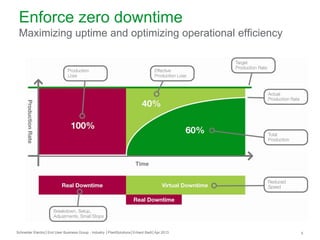

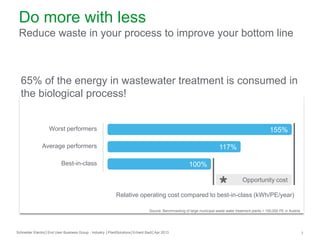

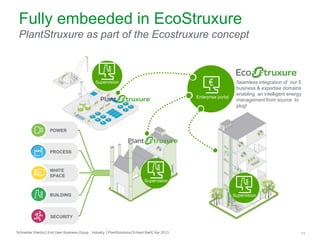

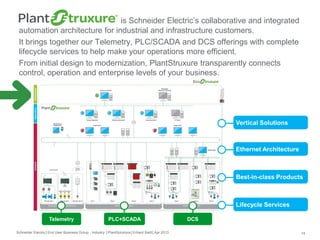

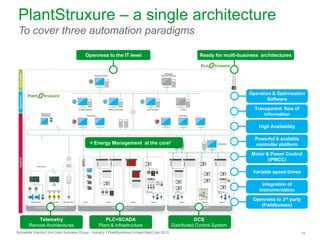

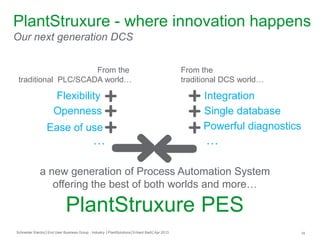

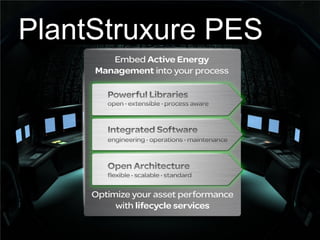

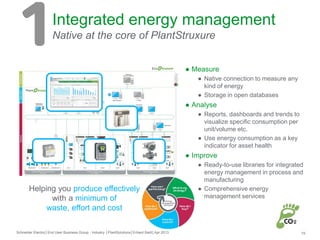

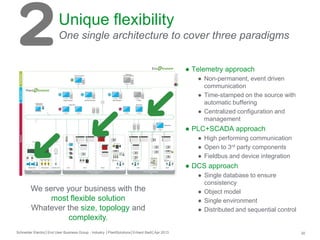

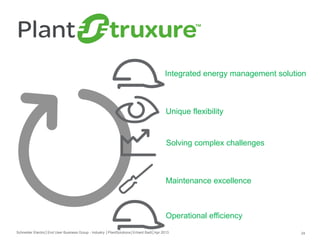

PlantStruxure is Schneider Electric's integrated automation architecture that unifies telemetry, PLC/SCADA, and DCS solutions to enhance operational efficiency throughout the lifecycle of industrial and infrastructure projects. It addresses key industry challenges such as safety, uptime, and regulatory compliance while offering a flexible and scalable architecture for diverse applications. The architecture aims to improve energy management and operational effectiveness by providing intelligent solutions tailored to the needs of various sectors.