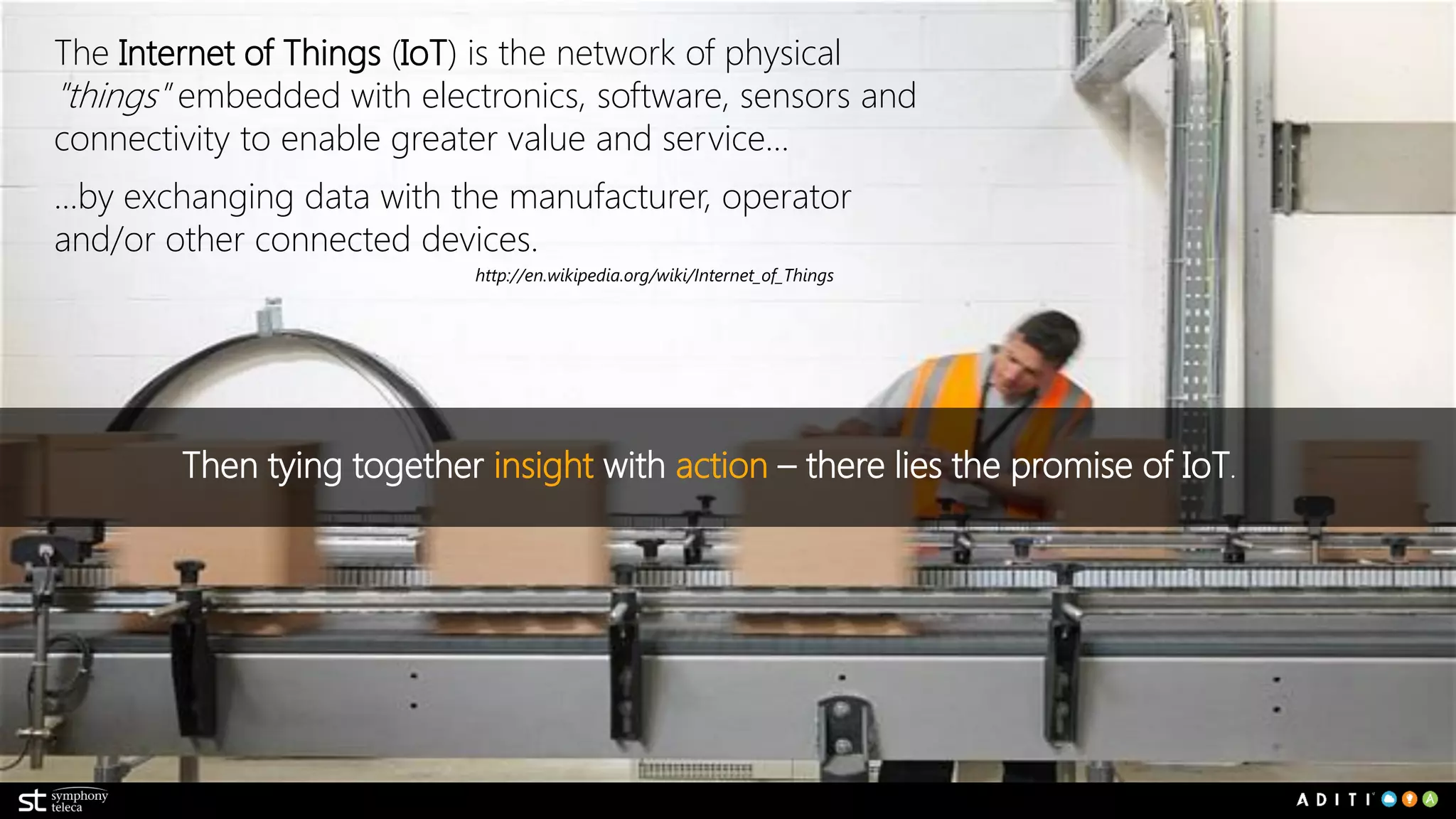

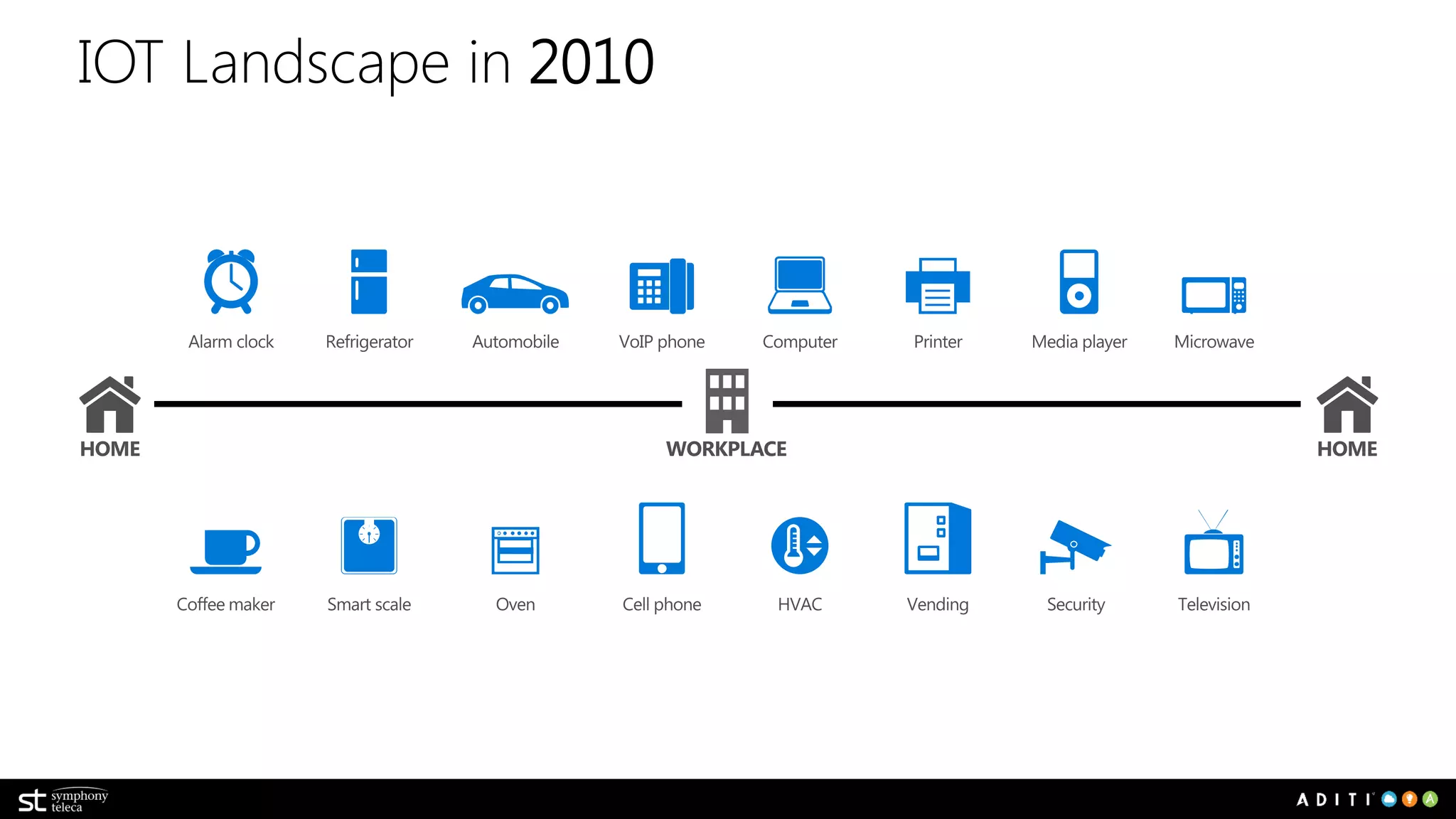

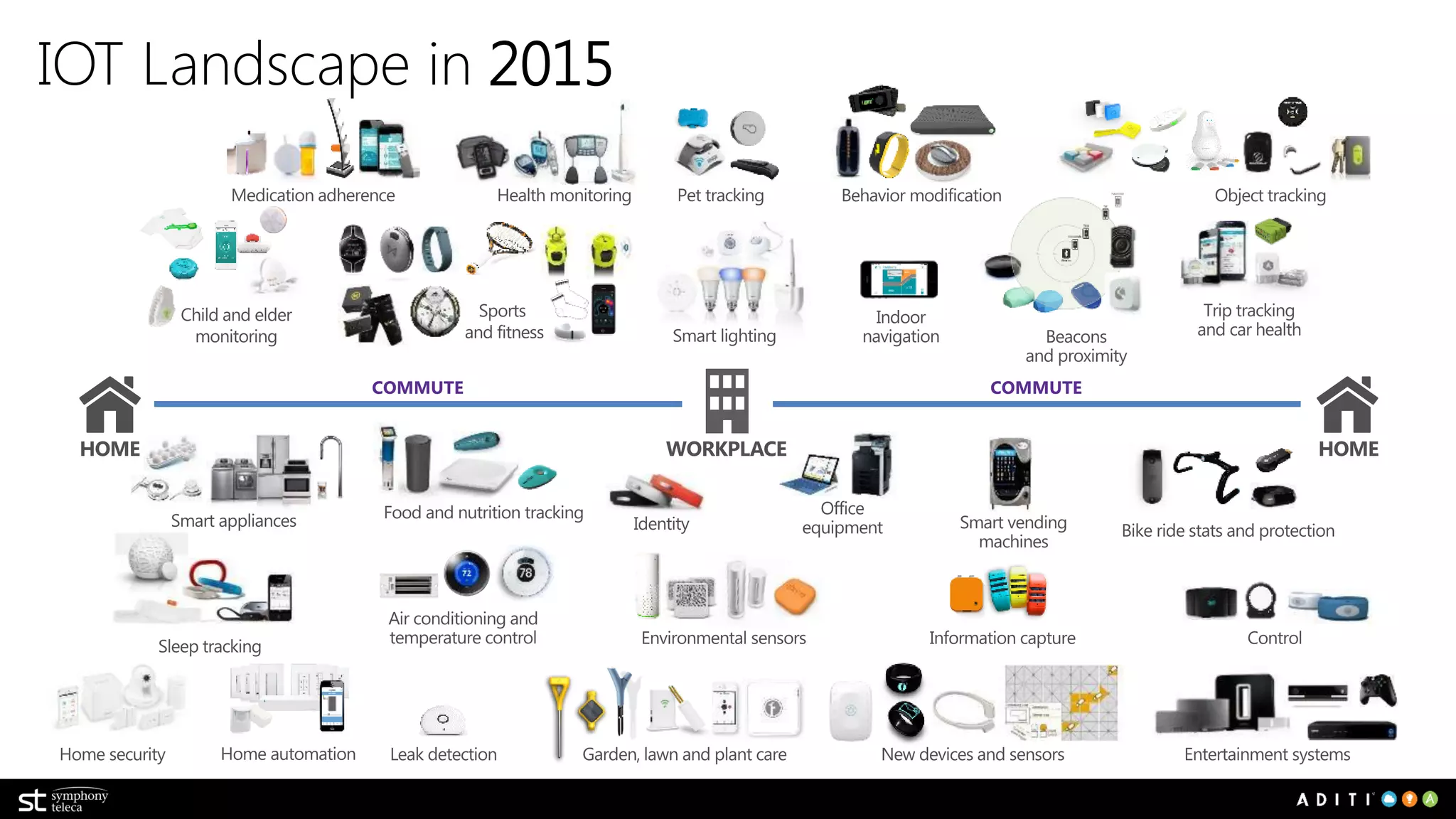

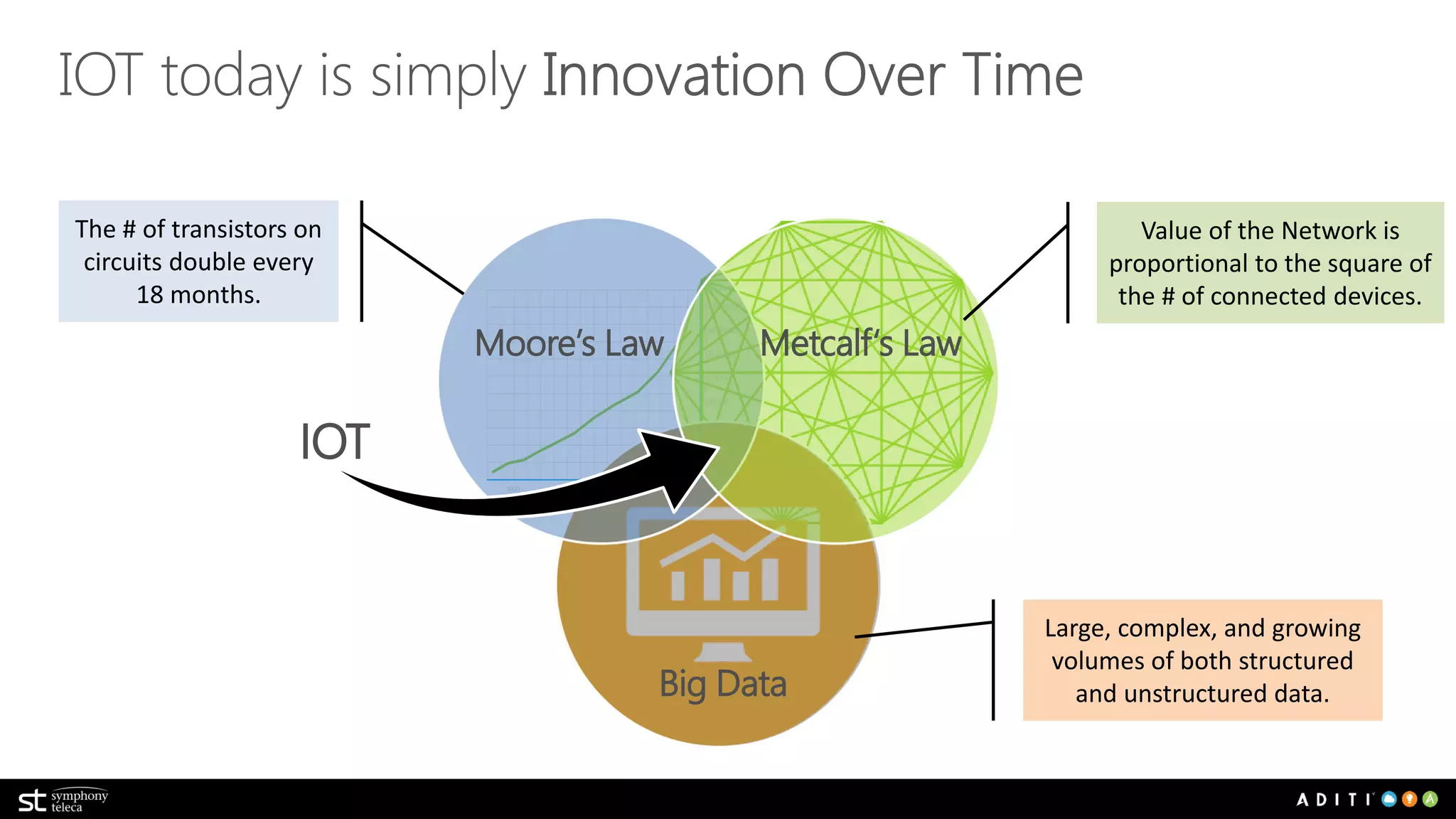

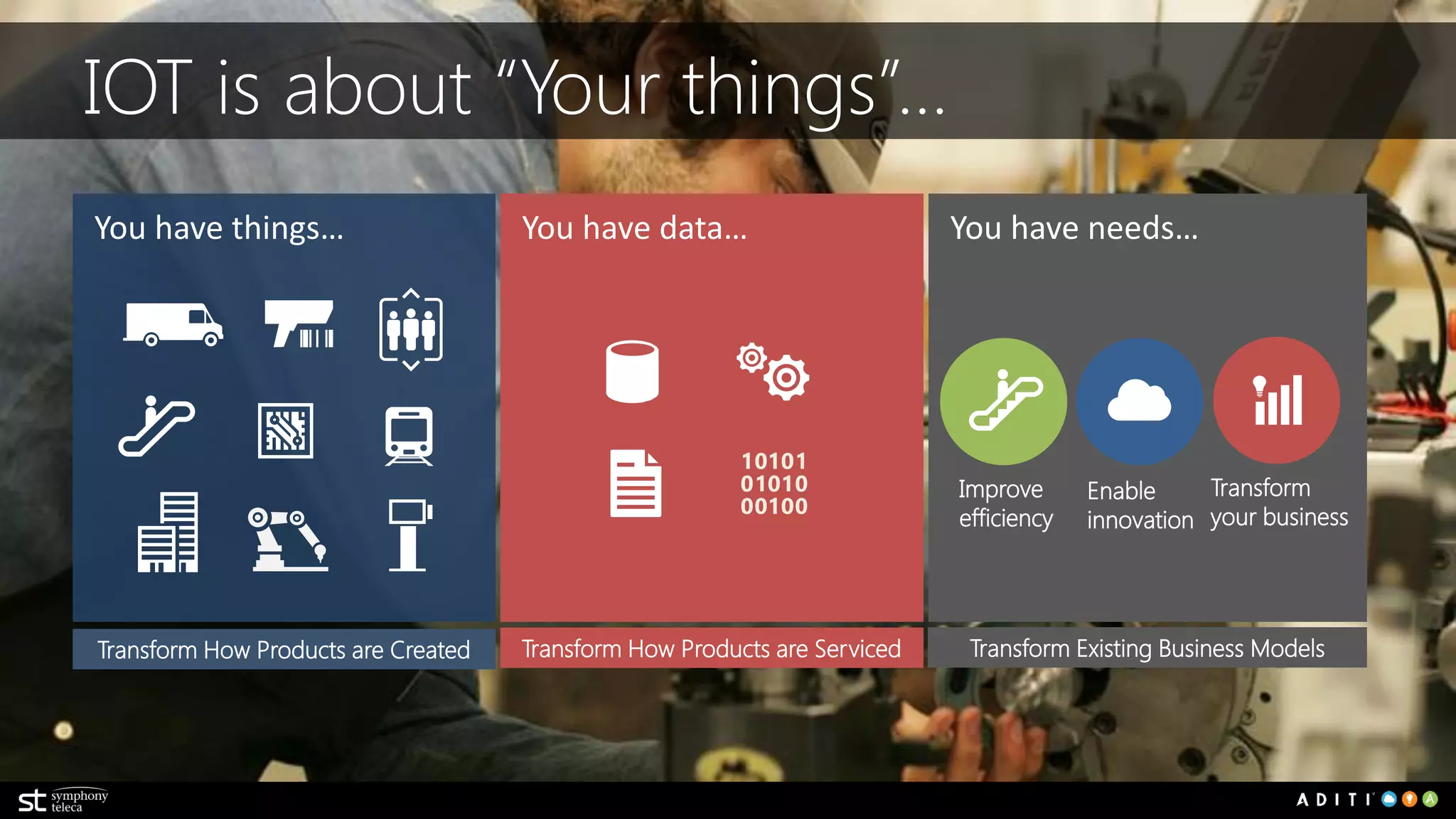

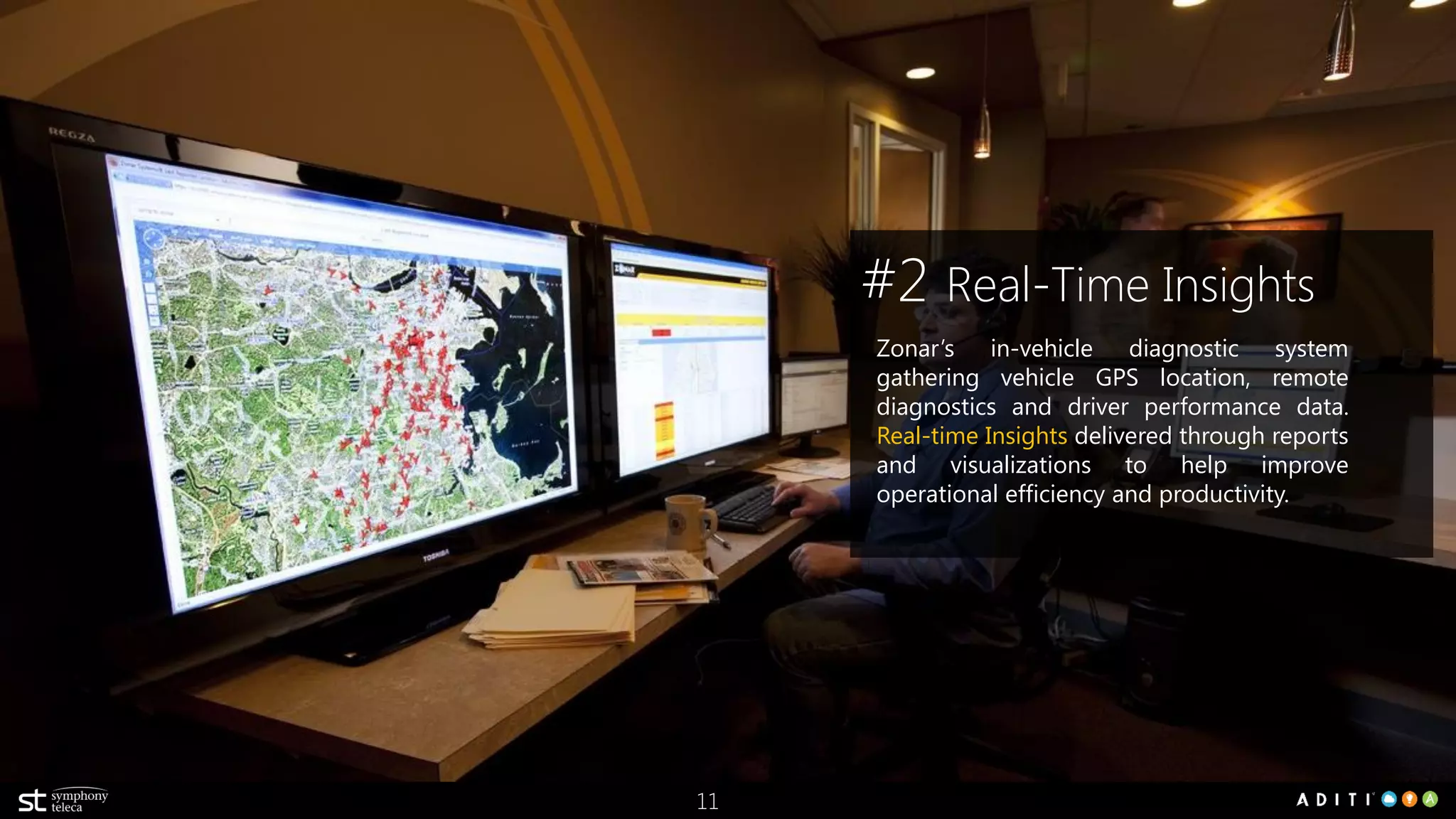

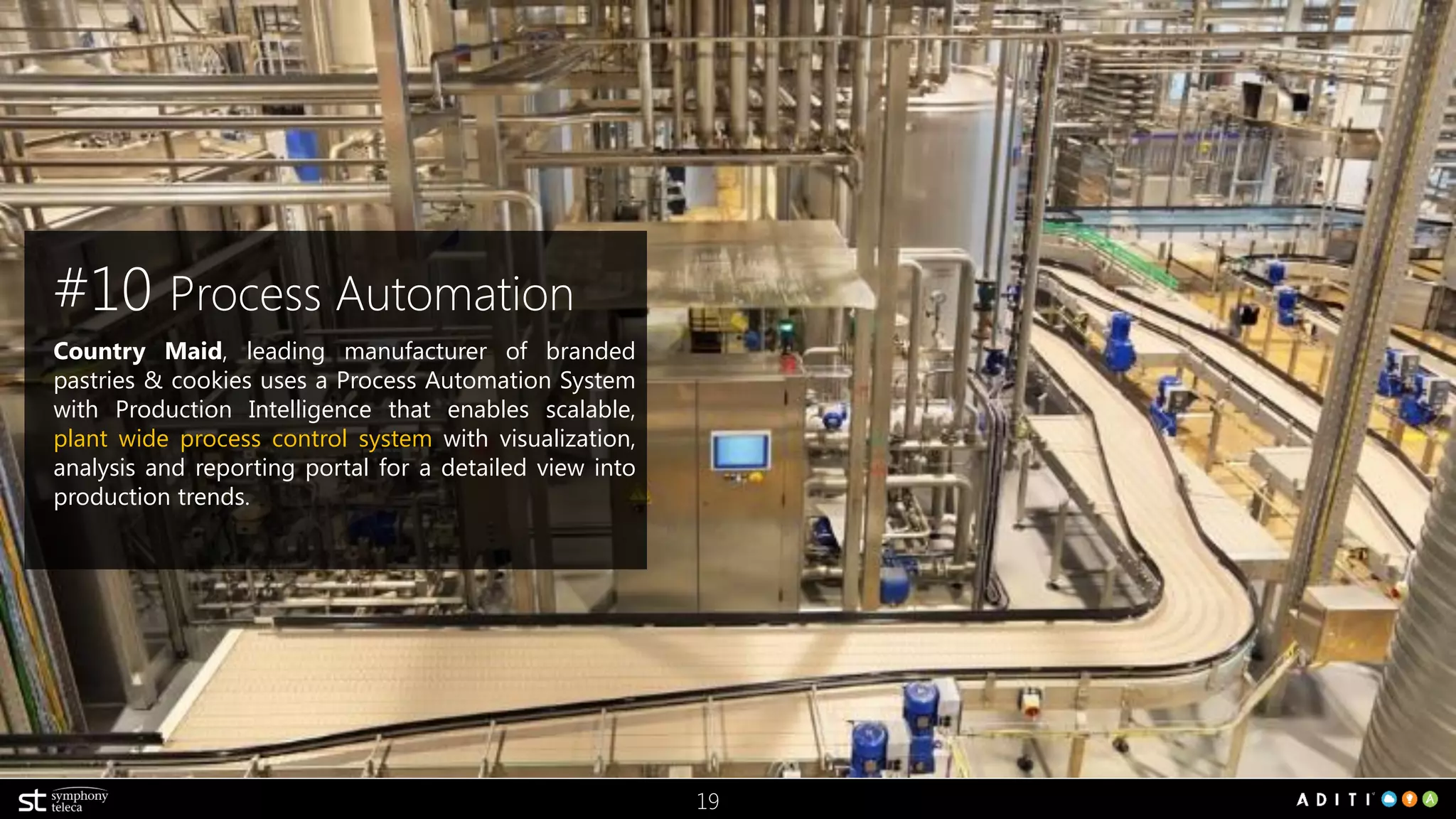

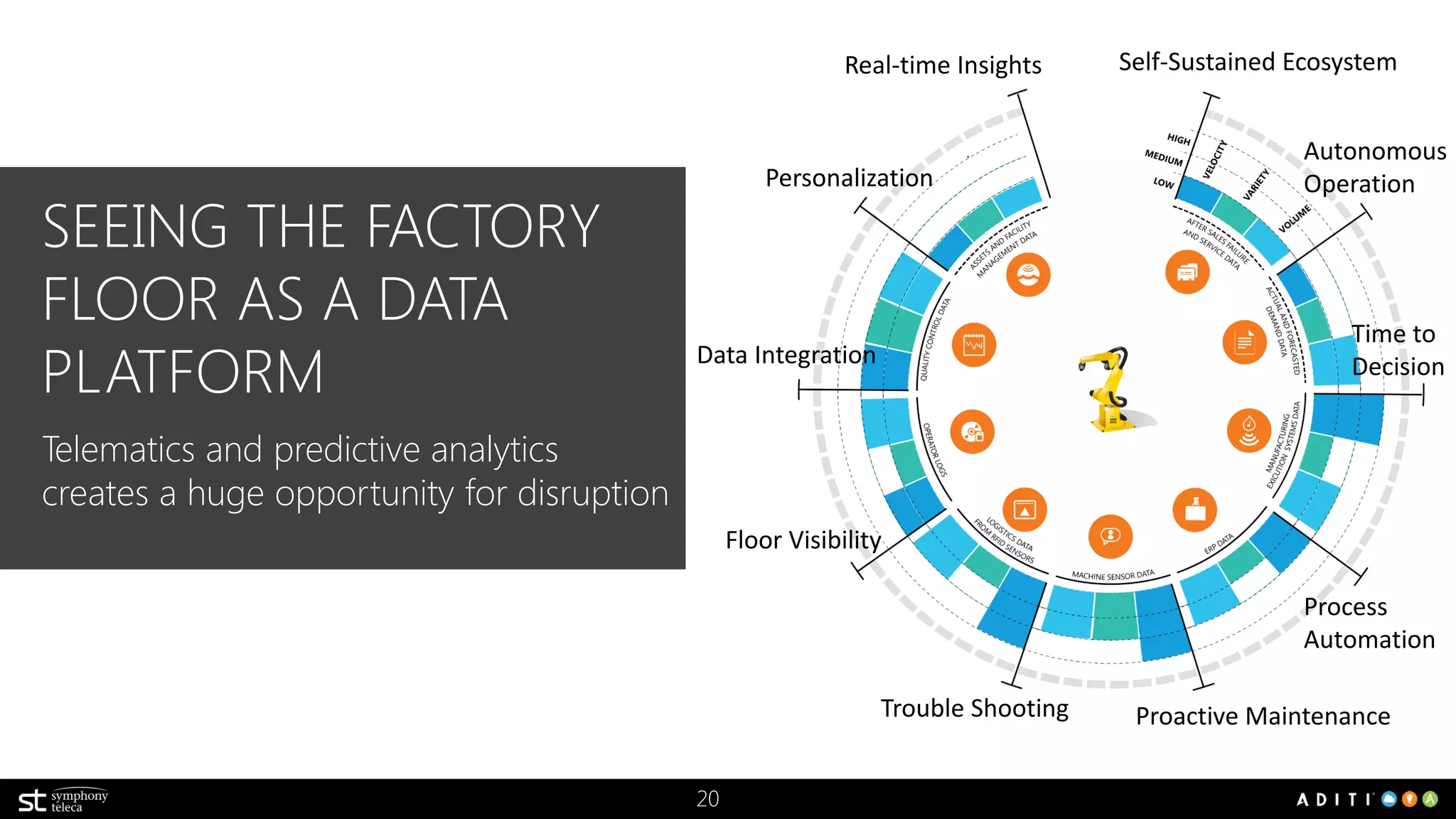

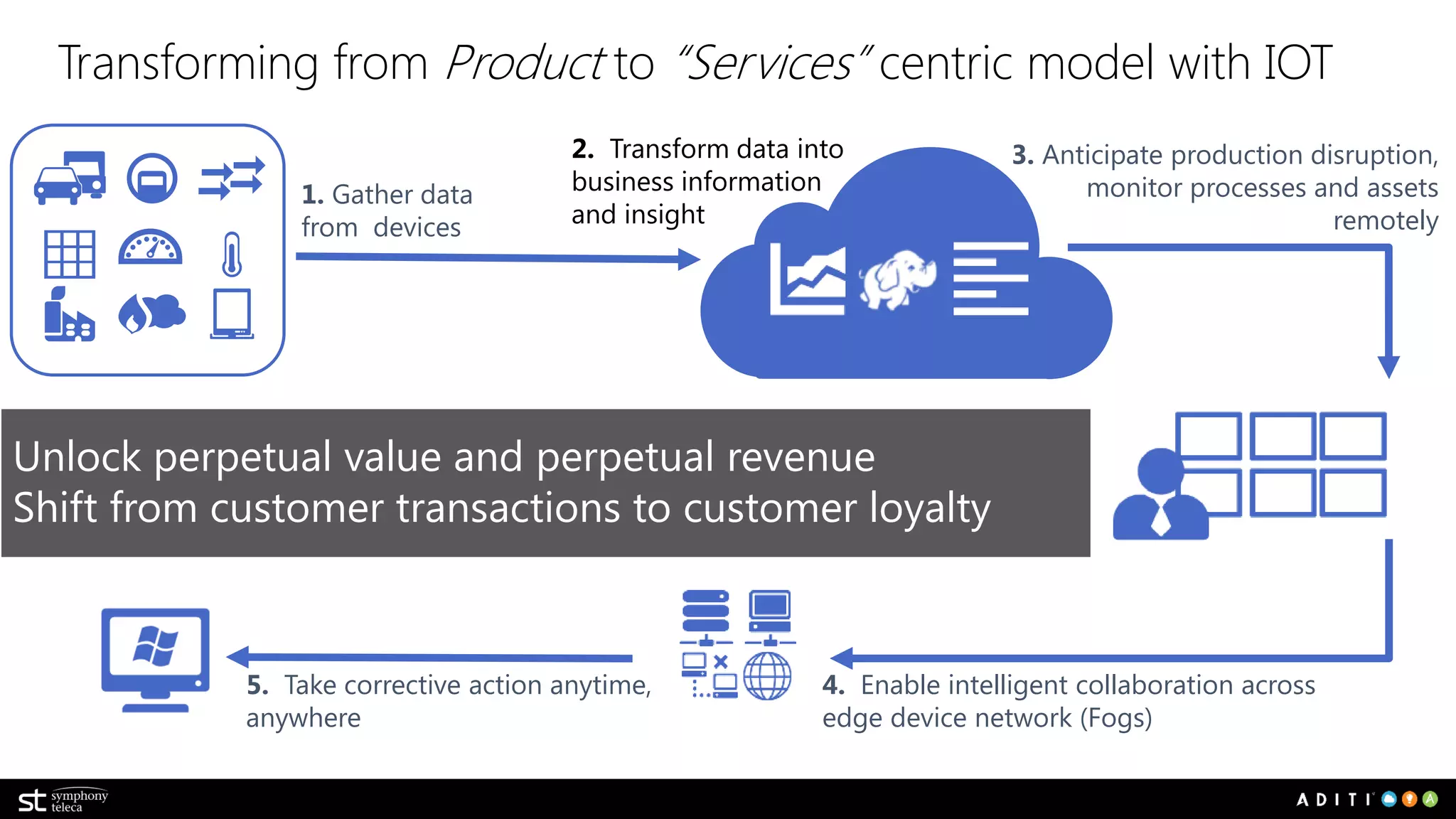

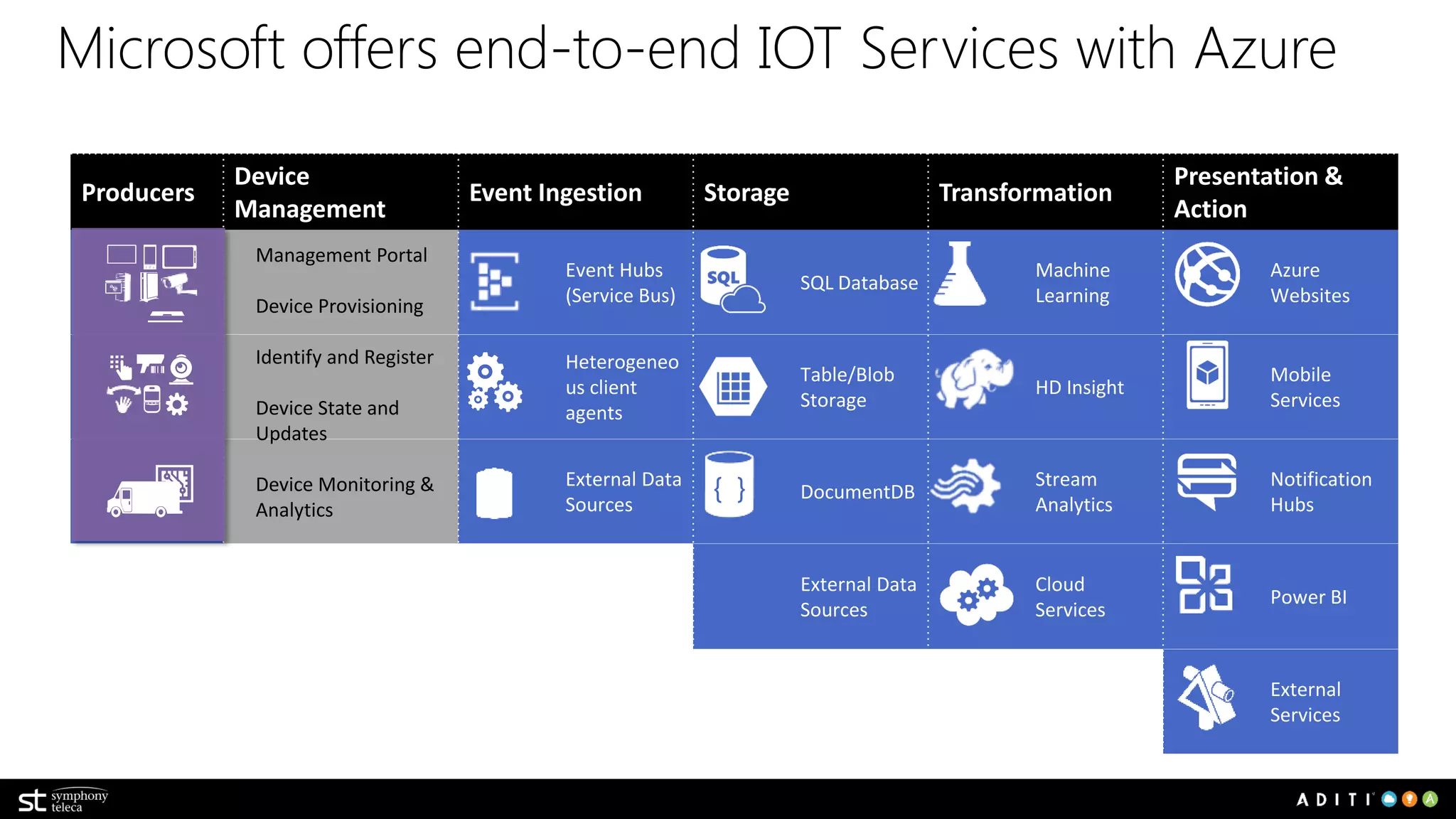

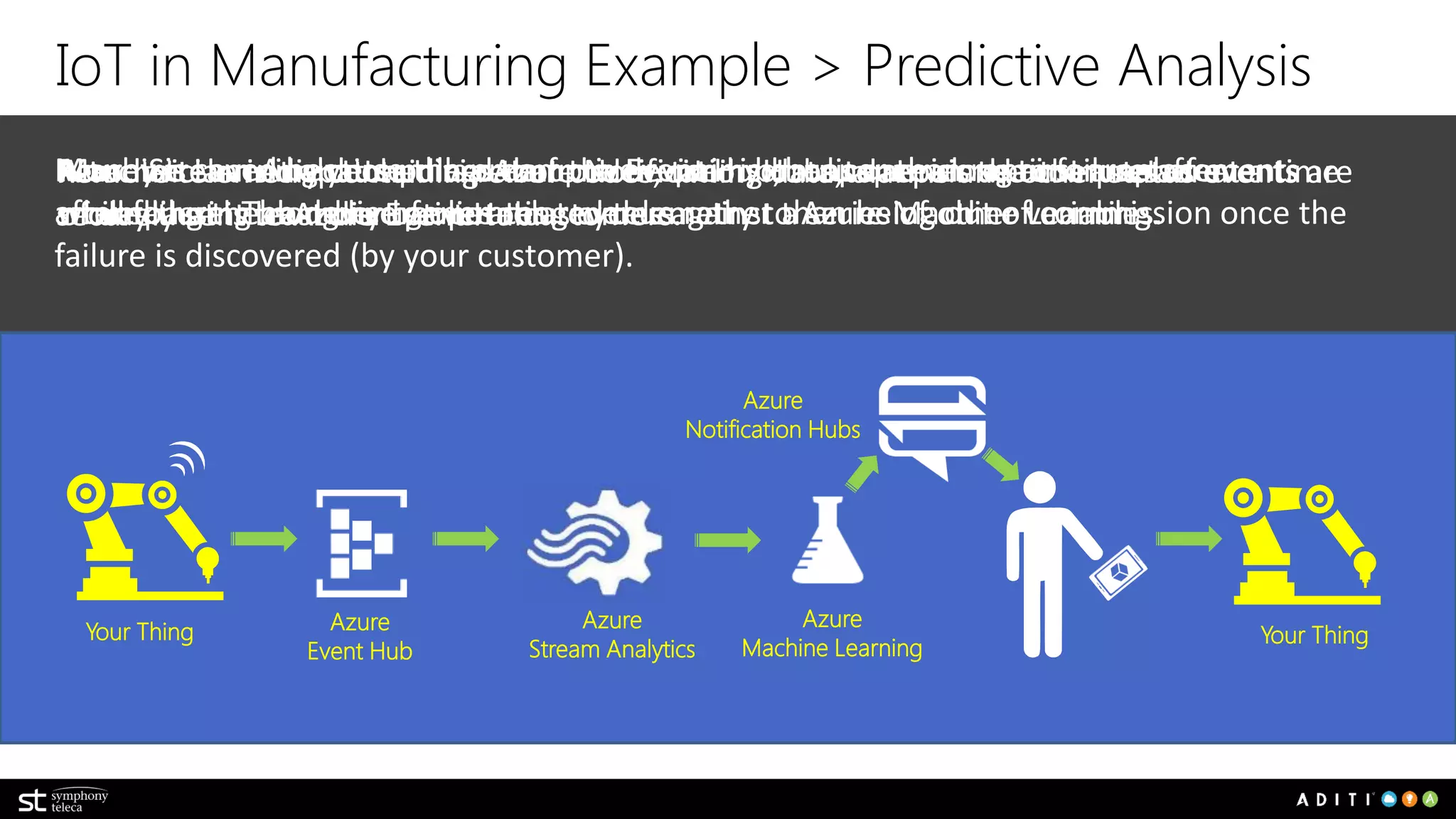

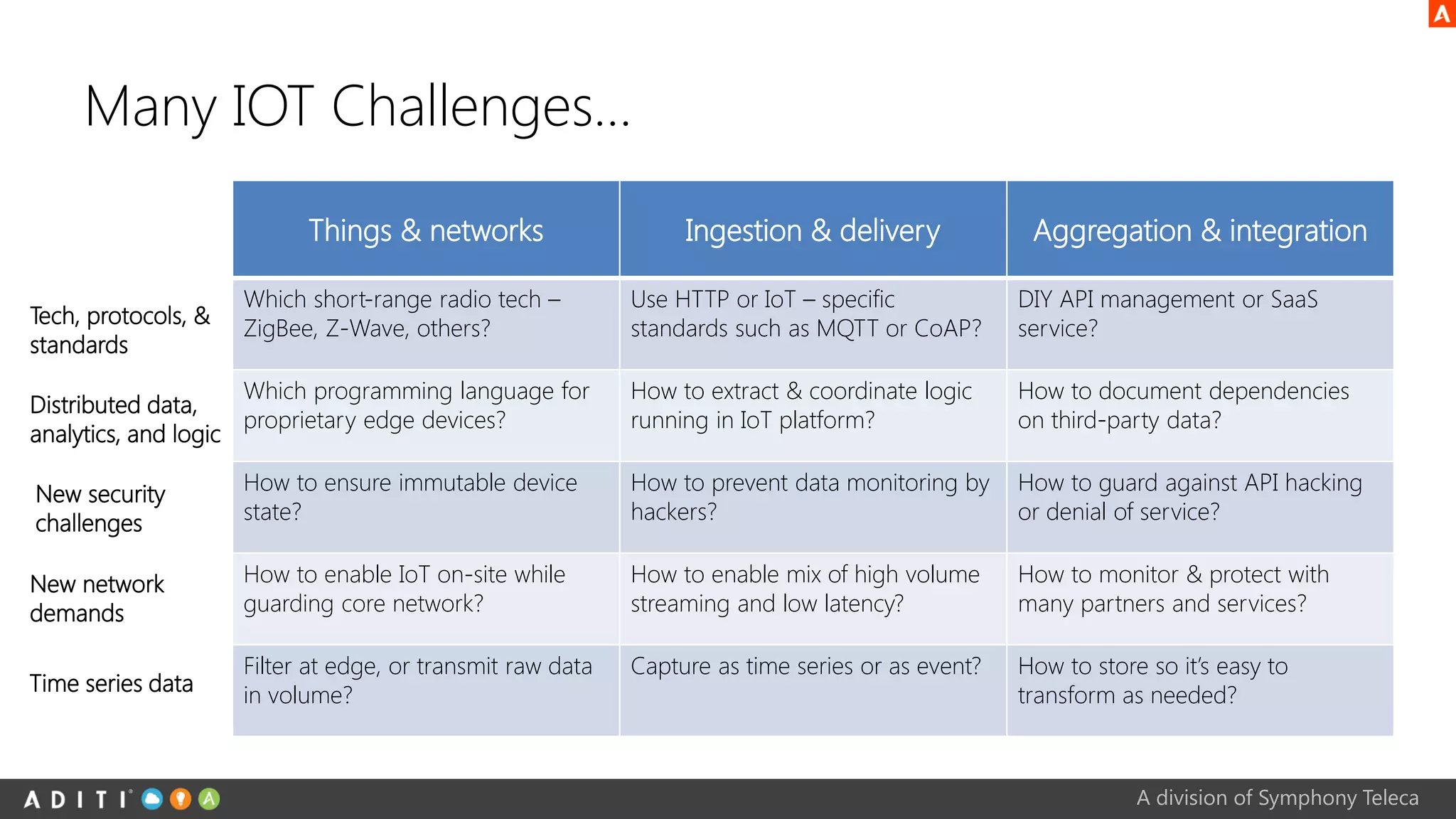

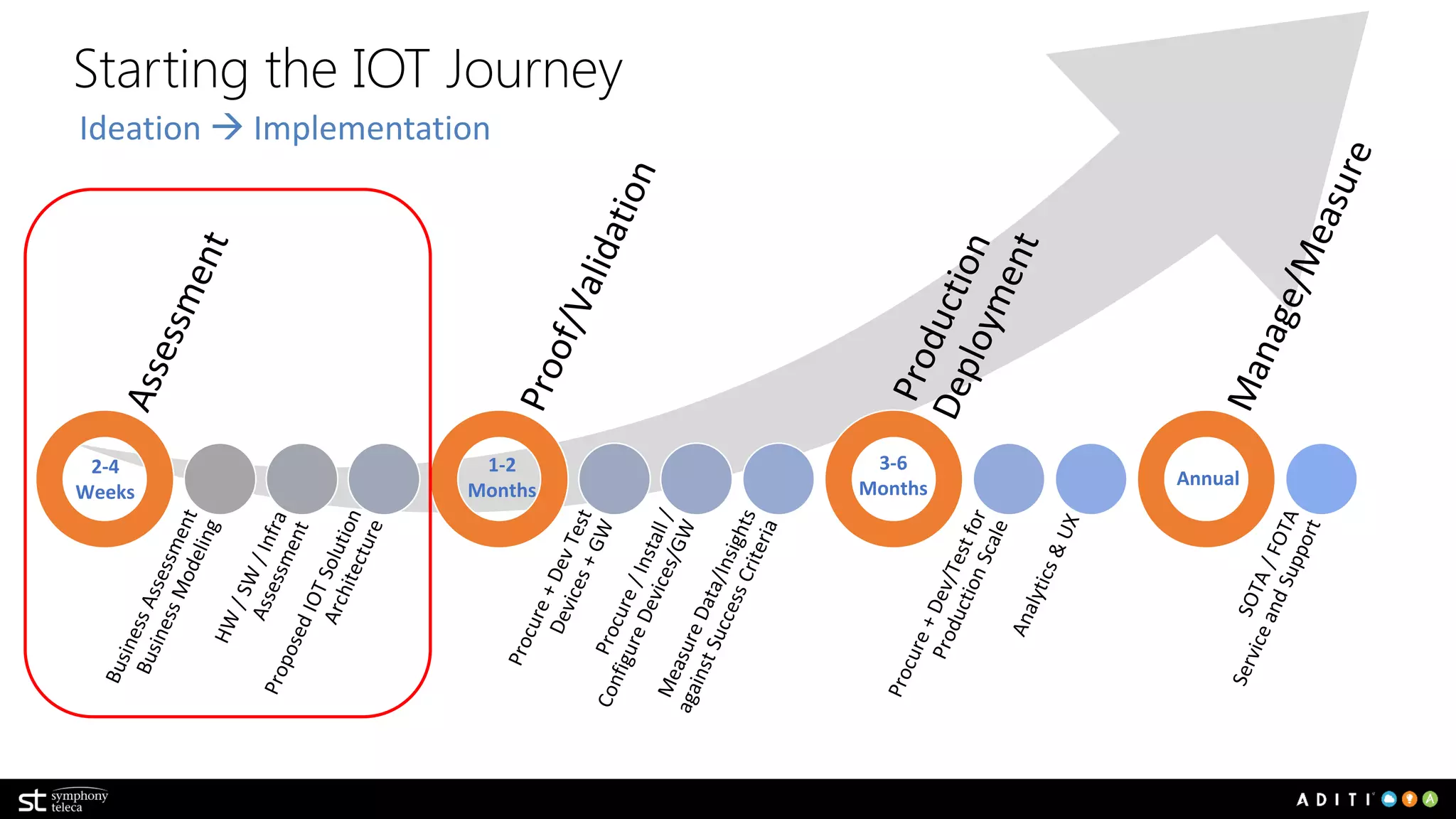

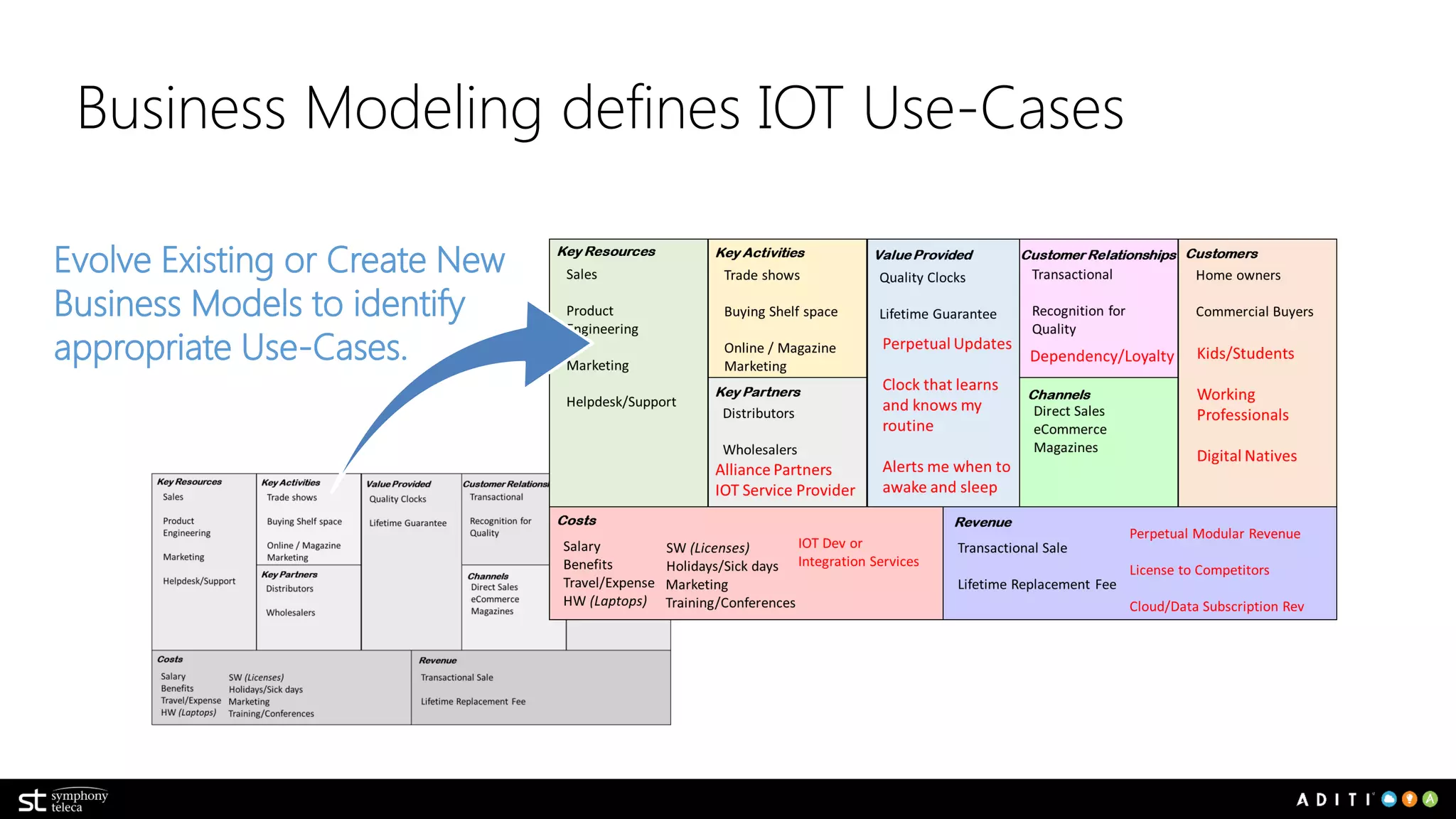

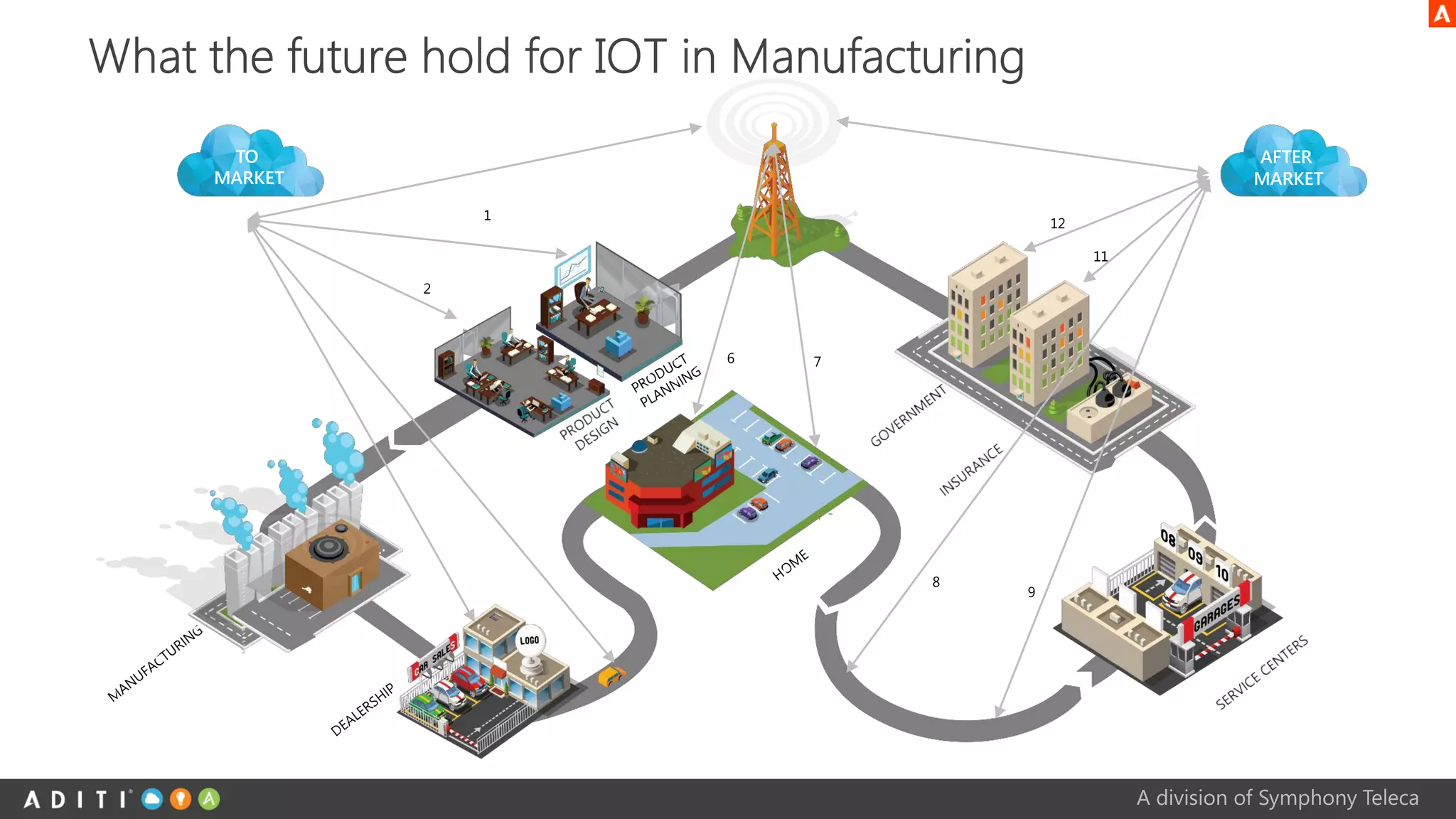

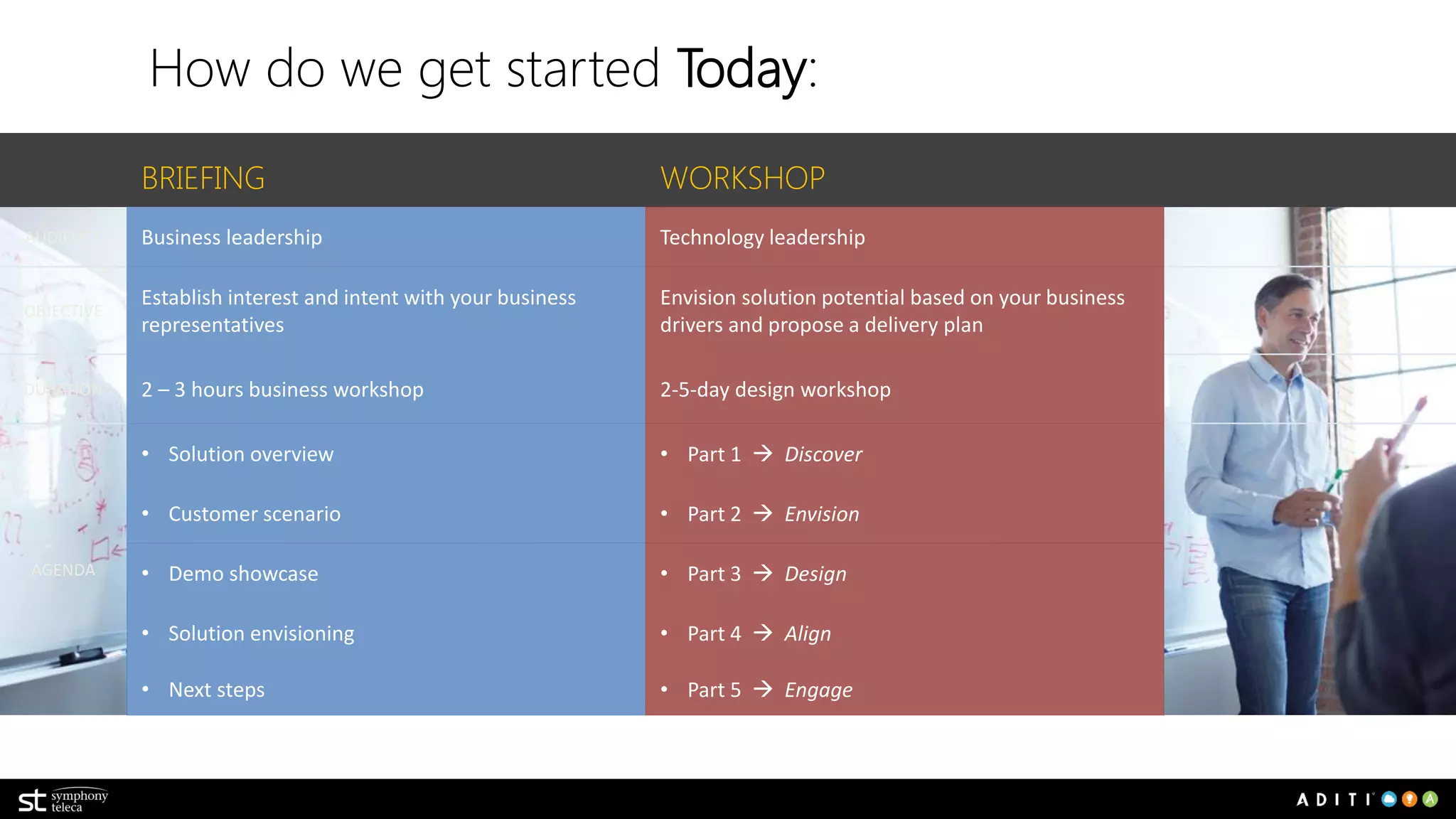

The document discusses the transformative impact of the Internet of Things (IoT) on manufacturing, shifting value from hardware to software and from products to services. It provides real-world examples of IoT applications that enhance personalization, efficiency, and operational capabilities in various industries. The aim is to guide businesses in leveraging IoT to create new business models and improve customer loyalty through data-driven insights and analytics.