Application of cement in various grade

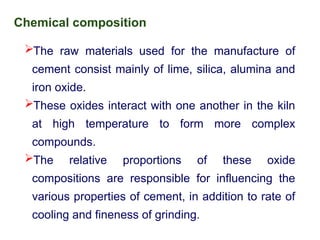

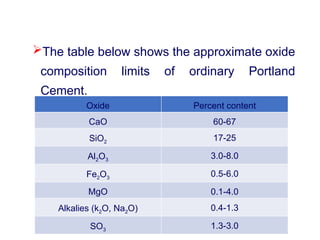

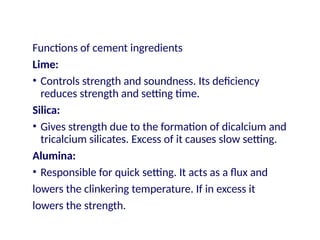

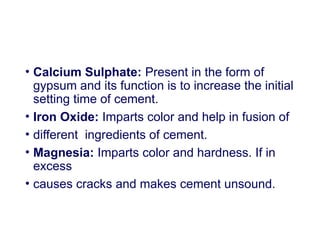

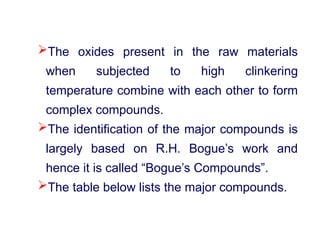

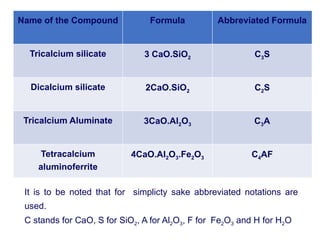

Cement and its composition

Properties of cement

Tests on cement

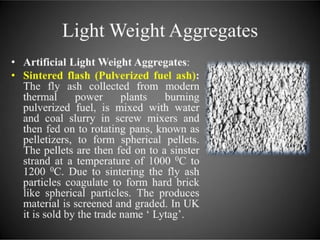

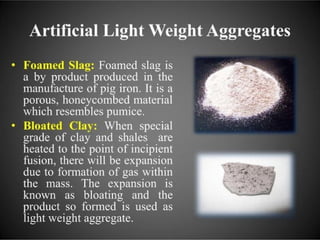

Aggregate and its classification

Grading and Tests on aggregate

Alkali aggregate reaction

Thermal properties aggregate

Water quality of water use in concrete

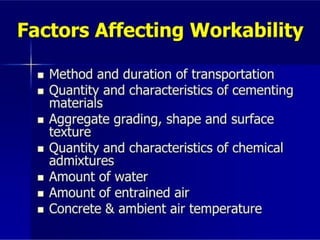

Accelerators ,Retarders

Plasticizers

Super Plasticizers

Water proofers

Mineral Admixtures

Fly ash, Silica fume

GGBS

Metakaoline

Effects on concrete properties