Cyanoacrylates

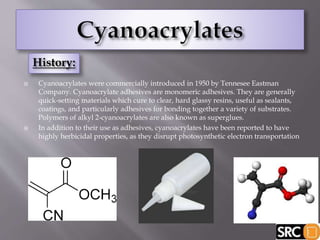

- 1. Cyanoacrylates were commercially introduced in 1950 by Tennesee Eastman Company. Cyanoacrylate adhesives are monomeric adhesives. They are generally quick-setting materials which cure to clear, hard glassy resins, useful as sealants, coatings, and particularly adhesives for bonding together a variety of substrates. Polymers of alkyl 2-cyanoacrylates are also known as superglues. In addition to their use as adhesives, cyanoacrylates have been reported to have highly herbicidal properties, as they disrupt photosynthetic electron transportation

- 2. In 1895 von Auwers and Thorpe attempted to synthesize diethyl-2,2- dicyanoglutarate by base-catalyzed condensation of aqueous formaldehyde and ethyl cyanoacetate. They isolated a mixture of oily oligomers and an amorphous polymer of higher molecular weight. In fact, ethyl cyanoacrylate monomer was synthesized as an intermediate, which underwent an immediate polymerization reaction. The condensation of formaldehyde with cyanoacetate is still the most important method for the commercial production of the monomers. The reaction mechanism takes place as a base-catalyzed Knoevenagel condensation of cyanoacetate and formaldehyde to give an intermediate disubstituted methylol derivative.

- 3. A.E. Ardis at B.F. Goodrich (in 1947) found that the polymer-oligomer mixture obtained in the formaldehyde-cyanoacetate condensation reaction could be thermally depolymerized with acid catalysts. However, the monomer prepared by utilizing these methods was unstable and the yields were low. Later it was realized that the water is responsible for polymerization. Instead of aqueous formaldehyde, paraformaldehyde was used with an organic solvent to remove the water by azeotropic distillation. The stability of the monomer can be enhanced by the redistillation of the crude monomer in the presence of small quantities of acidic stabilizers, e.g., sulfur dioxide. Several other methods for cyanoacrylate monomer production have been described, including the pyrolysis of 3-alkoxy-2-cyanopropionates , trans esterification of ethyl cyanoacrylate, and displacement of cyanoacrylate monomer from its anthracene Diels- Alder adduct by treatment with maleic anhydride. This last method is used for the synthesis of monomers that are not accessible or may be difficult to prepare by the retro polymerization route, for example difunctional cyanoacrylates , thiocyanoacrylates , and per fluorinated monomers. To improve the cohesive strength, difunctional monomeric crosslinking agents may be added to the monomer compositions. These include alkyl bis(2- cyanoacrylates), triallyl isocyanurates, alkylene diacrylates, alkylene dimethacrylates, trimethylol propane triacrylate, and alkyl bis(2-cyanoacrylates)

- 4. Commercial products consist mainly of monofunctional monomers. The monomers are usually low-viscosity liquids with excellent wetting properties. The monomers are usually low-viscosity liquids with excellent wetting properties. The basic structure of cyanoacrylate monomers and polymers is

- 5. The synthesis of the monomers and the raw materials are shown Because of the high electronegativity of the nitrile group and the carboxylate groups, they undergo rapid anionic polymerization on contact with basic catalysts. The anionic polymerization is facilitated by the possibility of resonance structures. The polymers formed in this way exhibit high molecular weights, usually more than 106 Da.

- 6. Adhesives based on cyanoacrylate esters are effective bonding agents for a wide variety of materials, but do not give a permanent bond in joints involving glass. A strong bond to glass is obtained initially but generally the joint fails after a period of weeks or months at room temperature conditions. The extremely rapid curing rate on glass caused by the basic nature of the surface is responsible for high stresses that are generated in the bond line immediately adjacent to the glass, at a molecular level. These stresses make the polymer in the bond line uniquely susceptible to chemical or physical degradation. For glass bonding, dibutyl phthalate is a suitable plasticizer in n-butyl cyanoacrylate Typical plasticizers include various alkyl esters and diesters and alkyl and aromatic phosphates and phosphonates, diallyl phthalates, and aryl and diaryl ethers. The bond strength decreases with increasing proportions of plasticizer. Levels greater than about 40% result in bonds of reduced strength.

- 7. Also, comonomers for cyanoacrylate polymers and polymeric additives have been described as plasticizers. The esters of 2-cyanoacrylic acid are also commonly called quick-set adhesives, since they generally harden after a few seconds when used or the joined parts exhibit at least a certain degree of initial strength. However, in the case of some substrates, especially acidic substrates such as wood or paper, the polymerization reaction may be very greatly delayed. Acidic materials exhibit a pronounced tendency to draw the adhesive, which is often highly liquid, out of the joint gap by capillary action before hardening has taken place in the gap. Therefore, attempts have been made to accelerate the polymerization for such applications by means of certain additives. The methods used may roughly be divided into three categories: 1. Addition of accelerators directly to the adhesive formulation. This is possible to only a very limited extent, however, since substances having a basic or nucleophilic action, which would normally bring about a pronounced acceleration of the polymerization of the cyanoacrylate adhesive, are generally used at the expense of the storage stability of such compositions.

- 8. 2. The second common method is the addition of the accelerators shortly before application of the adhesive in virtually a two-component system. However, this method has the disadvantage that the working life is limited after the activator has been mixed in. In addition, with the small amounts of activator that are required, the necessary accuracy of metering and homogeneity of mixing are difficult to achieve. 3. A third process is the use of activators in the form of a dilute solution. The solution is sprayed onto the parts before they are bonded onto the places where the adhesive is still liquid after the substrates have been joined. The solvents used for such dilute solutions of activators are generally low-boiling organic solvents. Silacrown compounds as additives give substantially reduced fixture and cure times on wood and other deactivating surfaces such as leather, ceramic, plastics, and metals with chromate-treated or acidic oxide surfaces. Silacrown accelerators have significantly lower reported acute toxicity than the crown ether compounds. The lower observed toxicity of silacrowns in comparison to crown ethers may be related to the hydrolytic instability of the Si–O–C linkage. Silacrowns are prepared by transesterification of alkoxysilanes with poly(ethylene glycol)s (PEGs), i.e., they are reaction products of silanes but are not themselves silanes.

- 9. Cyanoacrylate adhesive compositions that employ calixarene compounds as additives give substantially reduced fixture and cure times on wood and other deactivating surfaces such as leather, ceramic, plastics, and metals with chromate-treated or ceramic oxide surfaces Solutions of lower fatty amines, aromatic amines, and dimethylamine are used that are sprayed on the surface before the cyanoacrylate is applied, or at the same time. Examples are N,N-dimethylbenzylamine, N-methyl morpholine, and N,N- diethyltoluidine. N,N-Dimethyl-p-toluidine, when subsequently applied to the joined parts, causes even relatively large amounts of adhesive to harden within seconds. The poly(cyanoacrylate) so formed is completely free of turbidity. Disadvantages include the very high volatility of the substance, which does not permit long waiting times between the application of the accelerator solution to the substrates to be bonded and the subsequent bonding process. The compound is also toxic Examples of disulfides are dibenzodiazyl disulfide, 6,6-dithiodinicotinic acid, 2,2- dipyridyl disulfide, or bis(4-tert-butyl-1-isopropyl-2-imidazolyl) disulfide. The disulfides have a good accelerating action, but they nevertheless permit a long waiting time between application of the activator and application of the adhesive. In addition, they avoid spontaneous, merely superficial hardening.

- 10. Stabilizers have to be added both for the production and for storage. The stabilizer systems are added so that no polymerization occurs during transportation and storage in sealed drums, even at elevated temperatures and after long periods. After application polymerization occurs immediately. Accordingly, besides radical polymerization inhibitors, inhibitors against anionic polymerization are generally added to cyanoacrylate adhesives. Stabilizers are summarized in Table 13.6. A typical stabilizer to prevent radical polymerization is hydroquinone. Boron trifluoride prevents anionic polymerization.

- 11. Thickeners are added to increase the viscosity of 2- cyanoacrylate adhesive compositions. The 2-cyanoacrylate monomer generally has a low viscosity of several centipoise, and therefore the adhesive penetrates into porous materials such as wood and leather or adherents with a rough surface. Thus, good adhesion bond strengths are difficult to achieve. Thickeners are summarized as It has been proposed to add a strongly acidic cation exchanger as inhibitor. Cation exchangers are based on crosslinked poly(styrene)-containing sulfonic acid groups. The disadvantage of this approach is that the ion exchanger added can easily impede the outflow of the adhesive and that, as a solid, it does not act throughout the entire volume of the adhesive.

- 12. It has been proposed to modify the surface of storage containers for cyanoacrylate adhesives in such a way that they contain acid groups [32]. Although this proposal can be successfully implemented, it is afflicted by the problem that the inhibition occurs in the vicinity of the container wall. Sulfur Dioxide. Another method of stabilizing cyanoacrylate adhesives is to add sulfur dioxide as an inhibitor. Dioxathiolanes. Cyclic organic sulfates, sulfites, sulfoxides, and sulfinates, for example 2-oxo-1,3,2- dioxathiolanes, act in raising the ceiling temperature and hence to improve the thermal stability of the adhesives It is well known in the adhesive field that there are plastic substrates made from certain types of plastic materials which are extremely difficult to bond. Such difficult-to-bond materials include low surface energy plastics such as poly(ethylene) and poly(propylene) and highly crystalline materials such as polyacetals and poly(butylene terephthalate). As a consequence of the difficulty in bonding substrates made from these plastics materials with adhesives, various surface treatments have been employed where such materials require bonding.

- 13. 1,5-Diazabicyclo[4.3.0]non-5-ene, 1,8-diazabicyclo- [5.4.0]undec-7-ene, and 1,5,7- triazabicyclo[4.4.0]dec- 5-ene are shown

- 14. Compounds with a variety of highly branched architectures are known, including cascade, dendrimer, hyperbranched, and comb-like architectures. The term multi-amine compounds refers to compounds with such branched architectures in which branching occurs via tertiary amine groups. For example, polyamine dendrimers are prepared by the condensation of tris(2- aminoethyl)amine and dodecyl aldehyde followed by reduction with tetran- butylammonium cyanoborohydride . The reaction is shown as

- 15. Cyanoacrylates can be polymerized both by radical and by anionic mechanisms. The polymerization of cyanoacrylates has been monitored by Raman spectroscopy. with free-radical initiators. However, in the presence of catalytic amounts of anionic bases and in the presence of covalent bases such as amines and phosphines, they polymerize extremely rapidly. The exceptionally fast rate of anionic polymerization of cyanoacrylates in the presence of a base, including water, made this class of monomers unique among all acrylic and vinyl monomers. Consequently, the anionic polymerization is initiated by traces of moisture which are to be found on almost all surfaces. Accordingly, cyanoacrylate adhesives set very quickly when introduced between two surfaces stored under ambient conditions. Although the predominant mechanism by which cyanoacrylate monomers undergo polymerization is anionic, free-radical polymerization is also known to occur. Radical polymerization of cyanoacrylate can be achieved in the presence of a radical-forming component and a photosensitizer. The radical-generating component can be dibenzoyl peroxide and the photoinitiator component is 2,4,6-triphenylpyrylium tetrafluoroborate . The chemical structures of these compounds are shown

- 16. The particular advantage of cyanoacrylate adhesives in terms of adhesives technology lies precisely in the high reactivity coupled with the high bond strengths of the final materials, especially to polar substrates. Due to high molar mass, good wetting properties, and polarity, poly(cyanoacrylate)s exhibit excellent adhesive properties. In addition, they have been found useful as polymeric binding agents in controlled drug delivery systems. They are also useful for dry etching processes. Of the alkyl cyanoacrylate family of monomers, the methyl and ethyl esters are used extensively in industrial and consumer-type adhesives. Rapid Prototyping: A three-dimensional printing process uses a powder material as a substrate and a liquid binder as the ink. The three-dimensional printed specimens as such exhibit a porous structure and low mechanical strength. Therefore, three-dimensional prints are usually finished by an infiltration agent prior to their final use. For this, an epoxy resin, a cyanoacrylate, and a poly(urethane) are commonly used . The type of infiltration agent greatly influences the final properties of the prints. High-resolution Lithography: In the microelectronics industry involving the construction of micro machines or magneto resistive heads, there is a continued need to reduce the size of structural features . The ability to obtain a finer resolution is limited by the wavelength of the light used to create the lithographic pattern. The trend has been to move from so-called I-line radiation at 350–248 nm radiation with the goal to further reduce the wavelength.

- 17. Cosmetic and Medical Applications: Cyanoacrylates are also used as adhesives in the ordinary household. A case of an accidental aspiration of a cyanoacrylate adhesive has been reported . The use of cyanoacrylate compounds in medical applications has been reviewed . Poly(alkyl cyanoacrylate)s are biodegradable and biocompatible polymers. Ethyl cyanoacrylate, butyl cyanoacrylate, and octyl cyanoacrylate have been approved by the US Food and Drug Administration (FDA) . Such polymers have also been proposed as raw materials for the synthesis of nanoparticles to be used for drug delivery. Manicure Composition: Cyanoacrylate compositions are used as manicure compositions in treating chapped nails. When nails are manicured, it is generally observed that the moisture content in the nails becomes out of balance or lipids are eluted out from the nails. As a result, nail chapping proceeds under the manicure coating. Therefore, the nail chapping can be prevented by adding to manicure compositions a substance capable of keeping nails in good health or improving the nail health. Leak Control Embolization of Blood Vessel Ruptures: A traumatic rupture of the abdominal aorta commonly results in a rapid exsanguination and death before the patient reaches the hospital. In certain cases an open surgical repair can be performed. However, there are other methods, such as a repair using stent grafts. An embolization can be done using N-butyl- 2-cyanoacrylate with or without associated metallic coils

- 18. 2-Octyl cyanoacrylate was used as an adjunct to control air leaks after lung resection by application directly onto the visceral pleura. The indications of this treatment included a lack of standard sealants in patients with emphysematous lung that would not hold suture and vast air leaks after decortications or extensive nonanatomic resections in patients that would not tolerate the loss of tidal volume. All the air leaks sealed immediately. Cyanoacrylates can be used for skin surface biopsy because the polymers are formed with moisture and adhere to the skin . The stratum corneum is responsible for maintaining a skin barrier function. In a medical study, samples of the stratum corneum were collected for in vitro investigations . One drop of a cyanoacrylate resin was placed on a glass slide. Afterwards the glass slide was attached to the test site with slight pressure and after a short time of 1 min removed. The isobutyl, n-butyl, and n-octyl cyanoacrylate esters are used clinically as blocking agents, sealants, and tissue adhesives due to their much lower toxicity as compared with their more reactive methyl and ethyl counterparts. Cyanoacrylate ester compositions can be sterilized using visible light irradiation at room temperature.