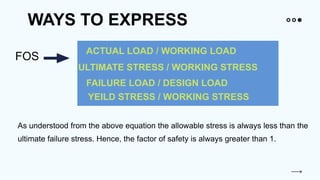

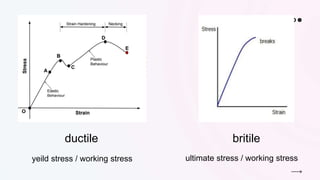

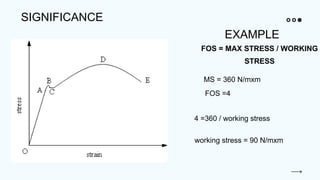

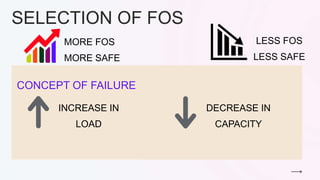

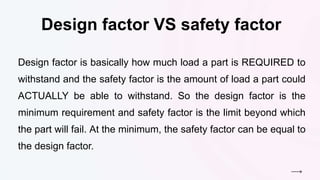

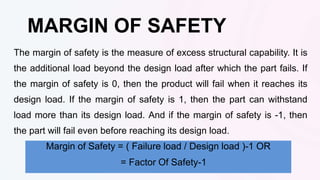

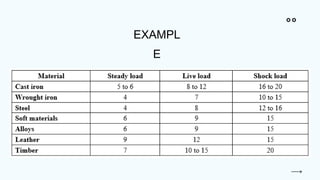

The document discusses the importance of the factor of safety (FOS) in machine design, emphasizing that components must be designed to withstand more load than their expected operational loads to ensure safety. It explains the implications of selecting appropriate FOS, including its impact on product reliability, regulatory approval, and market launch. The document also differentiates between design factor and safety factor, highlighting the need for an optimal FOS to avoid over-engineering while maintaining safety.